Mylar lamination offers superior durability and enhanced moisture resistance compared to PVC lamination, making it ideal for protecting sensitive documents and artwork. Unlike PVC, Mylar is environmentally friendly and does not release harmful chemicals when heated, ensuring safer use in various applications. Its clarity and strength provide a long-lasting, professional finish that preserves the integrity of laminated materials better than PVC options.

Table of Comparison

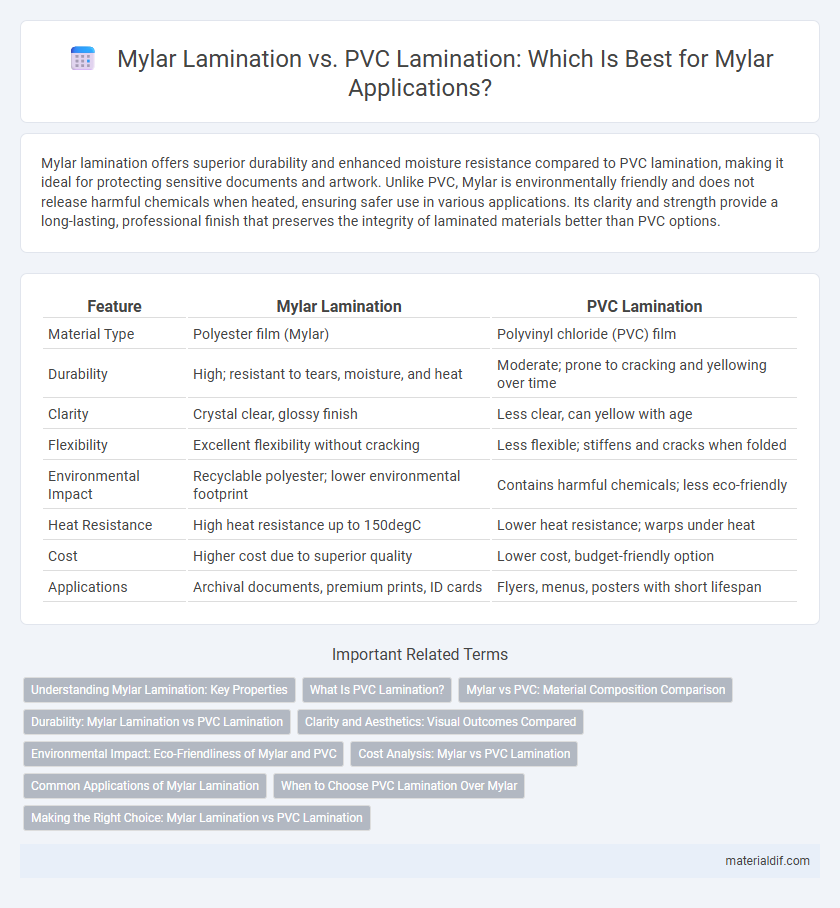

| Feature | Mylar Lamination | PVC Lamination |

|---|---|---|

| Material Type | Polyester film (Mylar) | Polyvinyl chloride (PVC) film |

| Durability | High; resistant to tears, moisture, and heat | Moderate; prone to cracking and yellowing over time |

| Clarity | Crystal clear, glossy finish | Less clear, can yellow with age |

| Flexibility | Excellent flexibility without cracking | Less flexible; stiffens and cracks when folded |

| Environmental Impact | Recyclable polyester; lower environmental footprint | Contains harmful chemicals; less eco-friendly |

| Heat Resistance | High heat resistance up to 150degC | Lower heat resistance; warps under heat |

| Cost | Higher cost due to superior quality | Lower cost, budget-friendly option |

| Applications | Archival documents, premium prints, ID cards | Flyers, menus, posters with short lifespan |

Understanding Mylar Lamination: Key Properties

Mylar lamination offers superior clarity, enhanced tensile strength, and excellent moisture resistance compared to PVC lamination, making it ideal for preserving documents and artwork. Its chemical stability ensures long-term durability without yellowing or cracking, unlike PVC which may degrade and emit harmful fumes over time. The eco-friendly nature of Mylar, being recyclable and free from plasticizers, further distinguishes it as a preferred choice for archival-quality lamination.

What Is PVC Lamination?

PVC lamination involves coating paper or fabric with a thin layer of polyvinyl chloride, enhancing durability, water resistance, and surface gloss. Unlike Mylar lamination, which uses polyester films known for superior clarity and temperature resistance, PVC lamination offers a more flexible and cost-effective solution but with lower environmental sustainability. This lamination method is commonly used for ID cards, menus, and book covers, providing a protective barrier against wear and tear.

Mylar vs PVC: Material Composition Comparison

Mylar lamination is made from biaxially-oriented polyethylene terephthalate (BoPET) film, offering high tensile strength, chemical stability, and excellent clarity. In contrast, PVC lamination uses polyvinyl chloride, which is less durable, prone to yellowing, and emits harmful chemicals over time. The inherent properties of Mylar provide superior moisture resistance and longevity compared to the more flexible but less stable PVC material.

Durability: Mylar Lamination vs PVC Lamination

Mylar lamination offers superior durability compared to PVC lamination due to its resistance to moisture, heat, and chemicals, ensuring long-lasting protection for printed materials. Unlike PVC, Mylar maintains clarity and flexibility over time without yellowing or cracking, making it ideal for high-wear applications. Its robustness against environmental factors extends the lifespan of laminated products, outperforming PVC in maintaining structural integrity.

Clarity and Aesthetics: Visual Outcomes Compared

Mylar lamination offers superior clarity and a glossy finish that enhances the vibrancy and sharpness of printed images, making it ideal for high-quality presentation materials. In contrast, PVC lamination tends to have a slightly opaque appearance that can dull colors and reduce overall visual impact. The smooth, transparent surface of Mylar preserves fine details and ensures long-lasting aesthetic appeal without yellowing over time.

Environmental Impact: Eco-Friendliness of Mylar and PVC

Mylar lamination offers a more eco-friendly alternative to PVC lamination due to its lower environmental toxicity and higher recyclability. Unlike PVC, which releases harmful dioxins and requires chlorine-based processing, Mylar is made from polyethylene terephthalate (PET), a material with less environmental impact and better energy efficiency during production. This makes Mylar lamination preferable for sustainable packaging and document protection applications where reducing ecological footprint is a priority.

Cost Analysis: Mylar vs PVC Lamination

Mylar lamination generally incurs higher upfront costs compared to PVC lamination due to its superior durability and resistance to heat and chemicals. PVC lamination offers a more budget-friendly option with adequate protection, making it ideal for projects with limited financial resources. Cost-effectiveness depends on application needs, as Mylar's longevity can reduce replacement expenses over time despite its initial investment.

Common Applications of Mylar Lamination

Mylar lamination is commonly used in high-end packaging, ID cards, and book covers due to its superior clarity, durability, and moisture resistance compared to PVC lamination. It provides excellent protection for documents and photographs while maintaining a glossy finish that enhances visual appeal. Industries such as electronics, food packaging, and printing frequently choose Mylar lamination for its thermal stability and chemical resistance.

When to Choose PVC Lamination Over Mylar

PVC lamination is preferred over Mylar when flexibility and cost-effectiveness are primary concerns, as PVC films offer better pliability for items needing frequent handling or folding. It is also advantageous for applications requiring strong chemical resistance or waterproofing, since PVC provides superior protection against moisture and solvents. For projects on a tight budget or where a softer finish is desired, PVC lamination delivers practical benefits without compromising durability.

Making the Right Choice: Mylar Lamination vs PVC Lamination

Mylar lamination offers superior clarity, durability, and resistance to moisture and heat compared to PVC lamination, making it ideal for preserving important documents and high-quality prints. PVC lamination is more cost-effective and flexible, suitable for short-term protection and budget-conscious projects. Choosing between Mylar and PVC lamination depends on the intended use, required longevity, and budget constraints.

Mylar Lamination vs PVC Lamination Infographic

materialdif.com

materialdif.com