UV-curable coatings provide a durable, scratch-resistant finish that cures quickly under ultraviolet light, enhancing the surface hardness without adding bulk. In contrast, Mylar lamination involves bonding a clear polyester film onto the substrate, offering superior protection against moisture, UV rays, and physical damage while maintaining flexibility. Choosing between UV-curable coatings and Mylar lamination depends on the desired balance of surface protection, durability, and aesthetic requirements.

Table of Comparison

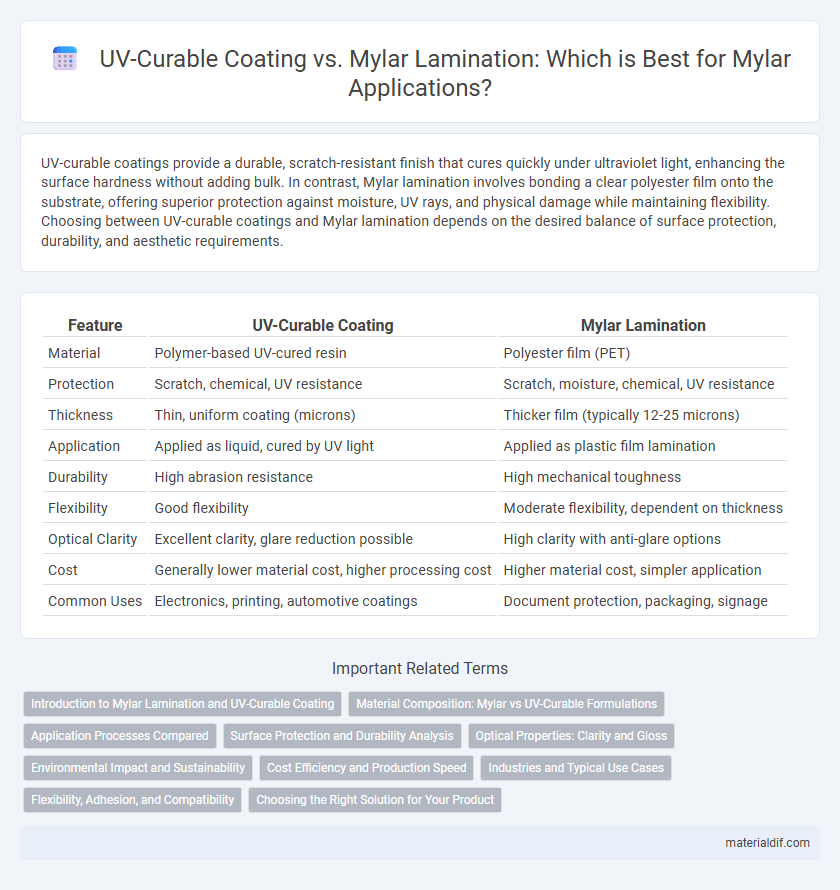

| Feature | UV-Curable Coating | Mylar Lamination |

|---|---|---|

| Material | Polymer-based UV-cured resin | Polyester film (PET) |

| Protection | Scratch, chemical, UV resistance | Scratch, moisture, chemical, UV resistance |

| Thickness | Thin, uniform coating (microns) | Thicker film (typically 12-25 microns) |

| Application | Applied as liquid, cured by UV light | Applied as plastic film lamination |

| Durability | High abrasion resistance | High mechanical toughness |

| Flexibility | Good flexibility | Moderate flexibility, dependent on thickness |

| Optical Clarity | Excellent clarity, glare reduction possible | High clarity with anti-glare options |

| Cost | Generally lower material cost, higher processing cost | Higher material cost, simpler application |

| Common Uses | Electronics, printing, automotive coatings | Document protection, packaging, signage |

Introduction to Mylar Lamination and UV-Curable Coating

Mylar lamination involves applying a thin polyester film to surfaces, enhancing durability, moisture resistance, and clarity for various packaging and print applications. UV-curable coating uses ultraviolet light to instantly harden a liquid coating, providing a tough, glossy finish that improves scratch and chemical resistance. Both technologies improve product longevity but differ in application methods and end-use performance characteristics.

Material Composition: Mylar vs UV-Curable Formulations

Mylar is a polyester film primarily composed of polyethylene terephthalate (PET), offering excellent durability, chemical resistance, and dimensional stability. UV-curable coatings consist of acrylate-based formulations containing photoinitiators that polymerize rapidly upon UV exposure, forming a hard, protective layer. The inherent flexibility and strength of Mylar differ significantly from the rigid, cross-linked structure of UV-cured coatings, impacting their applications in surface protection and finishing.

Application Processes Compared

UV-curable coating offers a rapid, environmentally friendly application process through UV light exposure, enabling instant curing and durable surface protection without the need for drying time. Mylar lamination involves applying a thin polyester film layer via heat and pressure, providing enhanced strength, moisture resistance, and a glossy finish but requires longer processing times and specialized equipment. The choice between UV-curable coating and Mylar lamination depends on production speed, desired surface qualities, and specific durability requirements in packaging or print industries.

Surface Protection and Durability Analysis

UV-curable coatings provide a hard, chemically resistant surface that enhances scratch and abrasion resistance beyond traditional Mylar lamination, which primarily offers physical barrier protection. The polymerized UV coatings form a cross-linked network that significantly improves durability against environmental factors such as moisture and UV exposure, whereas Mylar lamination mainly resists mechanical wear but can degrade under prolonged UV radiation. Surface protection by UV-curable coatings thus results in superior longevity and maintains optical clarity longer compared to Mylar laminated films.

Optical Properties: Clarity and Gloss

UV-curable coatings offer superior optical clarity and a higher gloss finish compared to Mylar lamination, making them ideal for applications requiring a seamless, glass-like appearance. Mylar lamination provides durable protection with moderate clarity but may exhibit slight haziness and reduced gloss under certain lighting conditions. The choice between UV-curable coating and Mylar lamination depends on the desired balance between optical performance and protective durability.

Environmental Impact and Sustainability

UV-curable coatings offer a more environmentally friendly alternative to Mylar lamination by eliminating the need for solvent-based adhesives and reducing VOC emissions. Unlike Mylar lamination, which relies on plastic films that contribute to long-term landfill waste and microplastic pollution, UV-curable coatings create a durable, recyclable surface with a lower carbon footprint. This sustainable approach supports greener manufacturing practices through energy-efficient curing and reduced material waste.

Cost Efficiency and Production Speed

UV-curable coatings offer higher cost efficiency than Mylar lamination due to reduced material waste and lower energy consumption during curing processes. Production speed is significantly faster with UV-curable coatings, as they cure instantly under UV light compared to the slower drying and cooling times required for Mylar lamination. This makes UV-curable coatings ideal for high-volume manufacturing environments where minimizing downtime and operational costs is critical.

Industries and Typical Use Cases

UV-curable coatings are widely used in electronics and automotive industries for their fast curing times and excellent chemical resistance, enabling durable protective layers on circuit boards and vehicle parts. Mylar lamination is prevalent in packaging, printing, and insulation sectors, offering superior moisture barrier properties and enhanced mechanical strength for flexible packaging, durable labels, and thermal insulation materials. Both technologies cater to industries requiring robust surface protection, but UV-curable coatings excel in high-precision, high-speed manufacturing, while Mylar lamination dominates applications demanding longevity and flexibility.

Flexibility, Adhesion, and Compatibility

UV-curable coatings offer superior flexibility compared to Mylar lamination, allowing better adaptation to curved or irregular surfaces without cracking. Adhesion strength of UV-curable coatings is generally higher due to chemical bonding with the substrate, ensuring long-lasting durability beyond the mechanical adhesion of Mylar films. UV-curable coatings provide broader compatibility with various substrates including plastics, metals, and glass, whereas Mylar lamination is primarily effective on flat surfaces and limited to certain materials.

Choosing the Right Solution for Your Product

UV-curable coatings offer rapid curing times and superior chemical resistance, making them ideal for high-performance applications requiring precision and durability. Mylar lamination provides enhanced flexibility, excellent barrier properties, and long-term protection against moisture and oxygen, suitable for packaging and display purposes. Selecting the right solution depends on factors such as product exposure, desired durability, clarity, and production speed, ensuring optimal performance and cost-efficiency.

UV-Curable Coating vs Mylar Lamination Infographic

materialdif.com

materialdif.com