Mylar tape offers superior heat resistance and durability compared to traditional electrical tape, making it ideal for insulation in high-temperature environments. Unlike electrical tape, which can stretch and degrade over time, Mylar tape maintains its structural integrity and electrical insulation properties for extended periods. Its thin, reflective surface also aids in protecting sensitive components from electrical interference and moisture.

Table of Comparison

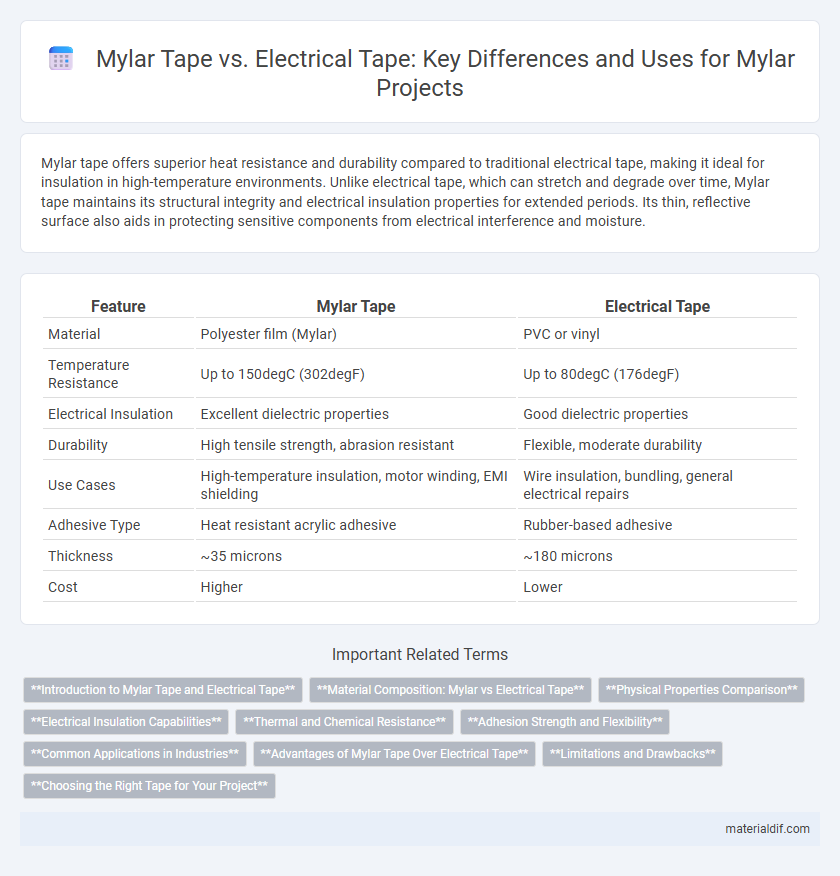

| Feature | Mylar Tape | Electrical Tape |

|---|---|---|

| Material | Polyester film (Mylar) | PVC or vinyl |

| Temperature Resistance | Up to 150degC (302degF) | Up to 80degC (176degF) |

| Electrical Insulation | Excellent dielectric properties | Good dielectric properties |

| Durability | High tensile strength, abrasion resistant | Flexible, moderate durability |

| Use Cases | High-temperature insulation, motor winding, EMI shielding | Wire insulation, bundling, general electrical repairs |

| Adhesive Type | Heat resistant acrylic adhesive | Rubber-based adhesive |

| Thickness | ~35 microns | ~180 microns |

| Cost | Higher | Lower |

Introduction to Mylar Tape and Electrical Tape

Mylar tape is a polyester film tape known for its high tensile strength, resistance to heat, chemicals, and moisture, making it ideal for insulation and reflective applications. Electrical tape, typically made from vinyl, offers flexibility and insulation properties designed for protecting electrical wires and components from abrasion, moisture, and corrosion. Understanding the material composition and performance differences between Mylar tape and electrical tape is crucial for selecting the appropriate tape in electrical and industrial environments.

Material Composition: Mylar vs Electrical Tape

Mylar tape is composed of biaxially-oriented polyethylene terephthalate (PET) film, known for its high tensile strength, thermal stability, and resistance to moisture and chemicals. Electrical tape typically consists of a vinyl (PVC) material that provides flexibility, electrical insulation, and moderate heat resistance. The polyester base of Mylar tape ensures superior durability and dimensional stability compared to the more elastic and softer vinyl composition of standard electrical tape.

Physical Properties Comparison

Mylar tape features high tensile strength and excellent thermal resistance, withstanding temperatures up to 250degC, making it ideal for insulating electrical components and protecting against abrasion. Electrical tape, typically made from vinyl or PVC, offers moderate heat resistance around 80degC and greater elasticity for flexible applications but lacks the durability and chemical resistance of Mylar tape. The thin, reflective surface of Mylar tape also provides superior dielectric strength and moisture resistance compared to the more porous structure of standard electrical tape.

Electrical Insulation Capabilities

Mylar tape offers superior electrical insulation capabilities due to its high dielectric strength and resistance to heat, chemicals, and moisture, making it ideal for demanding electrical applications. Electrical tape, typically made from vinyl, provides good insulation but may degrade faster under high temperatures or harsh environments, limiting its effectiveness over time. The enhanced thermal stability and electrical resistance of Mylar tape ensure reliable insulation performance in critical electrical and electronic components.

Thermal and Chemical Resistance

Mylar tape outperforms electrical tape in thermal and chemical resistance, withstanding temperatures up to 260degC compared to electrical tape's typical limit of 80degC. Its polyester film construction provides superior resistance to solvents, oils, and chemicals, making it ideal for high-temperature applications and harsh environments. Electrical tape, usually made of vinyl, degrades faster under heat and chemical exposure, limiting its durability in demanding conditions.

Adhesion Strength and Flexibility

Mylar tape offers superior adhesion strength with a polyester backing that maintains strong bonding on smooth surfaces, making it ideal for long-term insulation and heat resistance applications. Electrical tape provides excellent flexibility and stretchability, allowing it to conform easily around irregular shapes and wires but may have lower adhesion durability under high temperatures. Mylar tape's rigidity ensures dimensional stability, whereas electrical tape excels in elasticity and quick installation on curved surfaces.

Common Applications in Industries

Mylar tape is widely used in aerospace, automotive, and electronics industries for insulation, shielding, and labeling due to its heat resistance and durability. Electrical tape mainly finds application in electrical wiring, cable bundling, and insulation tasks within construction, telecommunications, and household electrical repairs. Both tapes offer unique properties, with Mylar tape favored for high-temperature environments and electrical tape preferred for general electrical insulation.

Advantages of Mylar Tape Over Electrical Tape

Mylar tape offers superior temperature resistance, maintaining stability in environments up to 260degC compared to electrical tape's lower heat tolerance. Its excellent electrical insulation and chemical resistance make it ideal for high-performance applications in electronics and aerospace industries. The dimensional stability and strength of Mylar tape prevent stretching and deformation, ensuring long-lasting, reliable protection that electrical tape often cannot provide.

Limitations and Drawbacks

Mylar tape has limited flexibility and can crack or peel when subjected to frequent bending or movement, making it less suitable for dynamic environments compared to electrical tape. Unlike electrical tape, Mylar tape offers lower adhesive strength on uneven or rough surfaces, reducing its long-term reliability in those conditions. Its resistance to stretch and lower elasticity also limit its effectiveness in applications requiring tight, conformal wrapping.

Choosing the Right Tape for Your Project

Mylar tape offers superior heat resistance, electrical insulation, and dimensional stability compared to traditional electrical tape, making it ideal for high-temperature or precision applications. Electrical tape provides flexibility and ease of use for general-purpose electrical insulation and minor repairs. Selecting the right tape depends on project requirements such as thermal endurance, dielectric strength, and mechanical durability.

Mylar Tape vs Electrical Tape Infographic

materialdif.com

materialdif.com