Mylar tape offers excellent tensile strength and electrical insulation, making it ideal for applications requiring durability and resistance to heat. Polyimide tape, renowned for its high-temperature resistance and chemical stability, excels in environments exposed to extreme heat and harsh conditions. Choosing between Mylar and polyimide tape depends on the specific thermal and mechanical requirements of the project.

Table of Comparison

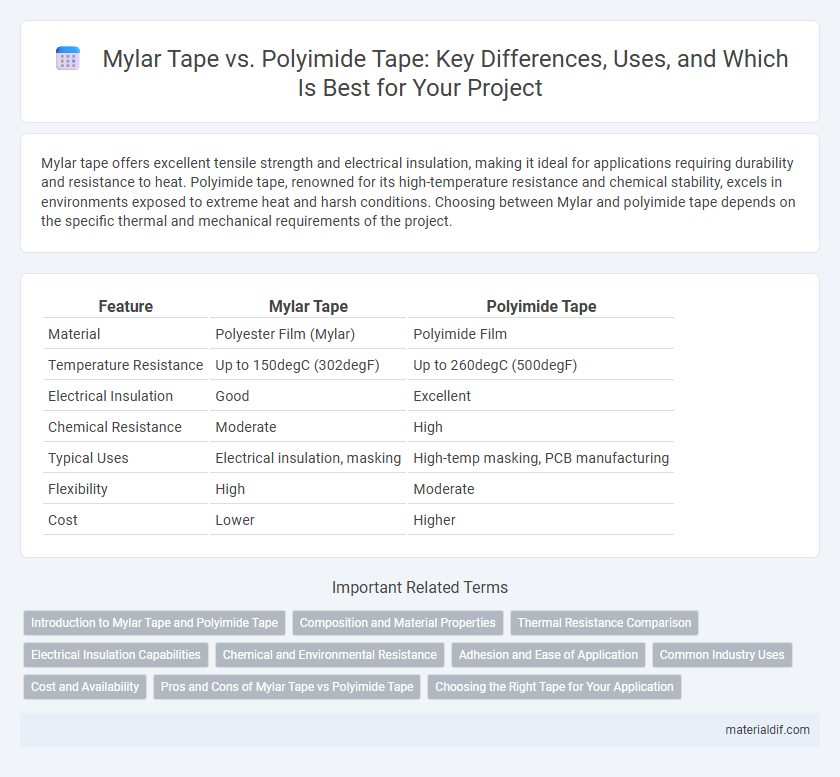

| Feature | Mylar Tape | Polyimide Tape |

|---|---|---|

| Material | Polyester Film (Mylar) | Polyimide Film |

| Temperature Resistance | Up to 150degC (302degF) | Up to 260degC (500degF) |

| Electrical Insulation | Good | Excellent |

| Chemical Resistance | Moderate | High |

| Typical Uses | Electrical insulation, masking | High-temp masking, PCB manufacturing |

| Flexibility | High | Moderate |

| Cost | Lower | Higher |

Introduction to Mylar Tape and Polyimide Tape

Mylar tape, made from biaxially oriented polyethylene terephthalate (PET), offers excellent tensile strength, electrical insulation, and chemical resistance, making it ideal for general-purpose electrical and sealing applications. Polyimide tape, composed of a heat-resistant polyimide film, provides superior thermal stability, withstanding temperatures up to 260degC, and is commonly used in high-temperature electronics and aerospace industries. While both tapes serve insulation and protection functions, Mylar tape excels in durability and chemical resistance, whereas polyimide tape is favored for its exceptional heat tolerance and dimensional stability.

Composition and Material Properties

Mylar tape is made from biaxially-oriented polyethylene terephthalate (PET), offering strong tensile strength, excellent dimensional stability, and UV resistance. Polyimide tape, composed of polyimide film, excels in high-temperature resistance, chemical stability, and electrical insulation properties. Mylar tape is ideal for general-purpose applications, while polyimide tape suits extreme thermal environments and demanding electrical insulation requirements.

Thermal Resistance Comparison

Mylar Tape, made from biaxially-oriented polyethylene terephthalate (PET), offers moderate thermal resistance, typically withstanding temperatures up to 150degC (302degF). Polyimide Tape, composed of polyimide film, exhibits superior thermal resistance, functioning efficiently in environments reaching 260degC (500degF) or higher. This significant difference makes Polyimide Tape more suitable for high-temperature applications such as electronics manufacturing and aerospace insulation.

Electrical Insulation Capabilities

Mylar tape offers excellent electrical insulation properties with a high dielectric strength, making it suitable for various electronic applications. Polyimide tape, however, withstands higher temperatures up to 260degC while maintaining superior electrical insulation performance in harsh environments. Selecting between Mylar and Polyimide tape depends on the temperature resistance requirements and the electrical insulation demands of the specific application.

Chemical and Environmental Resistance

Mylar tape exhibits excellent chemical resistance, particularly against solvents, oils, and mild acids, making it suitable for applications demanding durability in harsh environments. Polyimide tape, known for its superior thermal stability, also provides exceptional resistance to aggressive chemicals and high temperatures, outperforming Mylar in extreme conditions. Environmental resistance in Mylar tape includes good UV protection and moisture resistance, whereas polyimide tape excels in prolonged exposure to heat and chemical degradation.

Adhesion and Ease of Application

Mylar tape offers strong adhesion suitable for general applications, while polyimide tape provides superior heat resistance and maintains adhesive strength under high temperatures. Polyimide tape typically features a thinner, more flexible backing, making it easier to apply on uneven surfaces compared to the stiffer Mylar tape. The choice between the two depends on the specific environmental conditions and surface requirements, with polyimide tape excelling in electronic and thermal insulation tasks.

Common Industry Uses

Mylar tape is commonly used in electrical insulation, packaging, and heat sealing applications due to its high tensile strength and resistance to moisture and chemicals. Polyimide tape, often recognized by its amber color, excels in high-temperature environments such as circuit board manufacturing, solder masking, and 3D printing. Both tapes play crucial roles in electronics and industrial settings, with Mylar favored for durability and polyimide for thermal stability.

Cost and Availability

Mylar tape is generally more affordable and widely available compared to polyimide tape, making it a cost-effective choice for many industrial and electrical applications. Polyimide tape, known for its high-temperature resistance and superior insulation properties, tends to be more expensive and less readily accessible in standard retail outlets. Businesses prioritizing budget and ease of procurement often opt for Mylar tape, while specialized environments with high thermal demands favor polyimide variants despite the higher cost.

Pros and Cons of Mylar Tape vs Polyimide Tape

Mylar tape offers excellent tensile strength and dimensional stability, making it ideal for applications requiring durability and resistance to stretching, while its lower heat resistance compared to polyimide tape limits use in high-temperature environments. Polyimide tape excels in thermal stability, withstanding temperatures up to 260degC, which is vital for electronics and soldering processes, but it is generally less resistant to tearing and abrasion than Mylar tape. Choosing between Mylar and polyimide tapes involves balancing the need for high-temperature performance against mechanical durability and flexibility.

Choosing the Right Tape for Your Application

Mylar tape offers excellent tensile strength and electrical insulation, making it ideal for general-purpose use in electronics and packaging, while polyimide tape excels in high-temperature environments up to 260degC, providing superior chemical and thermal resistance for demanding aerospace and industrial applications. Selecting the right tape depends on factors like operating temperature, chemical exposure, and mechanical stress; Mylar tape suits applications with moderate heat and less aggressive conditions, whereas polyimide tape ensures durability and performance under extreme thermal cycling and harsh chemicals. Understanding these distinctions enhances the reliability and safety of your project by matching tape properties to application requirements.

Mylar Tape vs Polyimide Tape Infographic

materialdif.com

materialdif.com