Mylar wrapping offers superior moisture and oxygen barrier properties compared to traditional aluminum wrapping, making it ideal for preserving pet food freshness. Its lightweight and flexible nature allows for easier handling and better sealing, ensuring extended shelf life for pet products. Unlike aluminum, Mylar is also puncture-resistant and less prone to tearing, providing enhanced durability during storage and transportation.

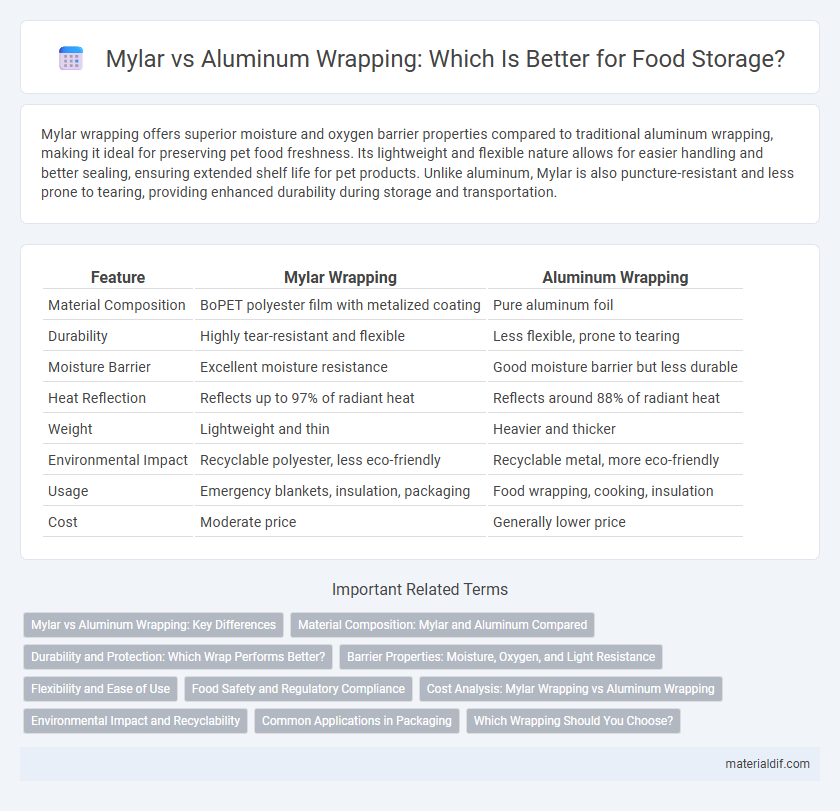

Table of Comparison

| Feature | Mylar Wrapping | Aluminum Wrapping |

|---|---|---|

| Material Composition | BoPET polyester film with metalized coating | Pure aluminum foil |

| Durability | Highly tear-resistant and flexible | Less flexible, prone to tearing |

| Moisture Barrier | Excellent moisture resistance | Good moisture barrier but less durable |

| Heat Reflection | Reflects up to 97% of radiant heat | Reflects around 88% of radiant heat |

| Weight | Lightweight and thin | Heavier and thicker |

| Environmental Impact | Recyclable polyester, less eco-friendly | Recyclable metal, more eco-friendly |

| Usage | Emergency blankets, insulation, packaging | Food wrapping, cooking, insulation |

| Cost | Moderate price | Generally lower price |

Mylar vs Aluminum Wrapping: Key Differences

Mylar wrapping offers superior moisture resistance and durability compared to aluminum wrapping, making it ideal for long-term food storage and insulation. Unlike aluminum, Mylar is lightweight, flexible, and tear-resistant, which enhances its usability in packaging and emergency blankets. While aluminum wrapping excels in heat reflection, Mylar provides better protection against oxygen and light, preserving freshness more effectively.

Material Composition: Mylar and Aluminum Compared

Mylar consists of stretched polyethylene terephthalate (PET) film coated with metal or clear layers, providing lightweight durability and superior moisture resistance. Aluminum wrapping is made from thin sheets of pure aluminum, offering excellent heat conductivity and barrier properties against light and oxygen. Mylar's flexible polymer base makes it less prone to tearing than aluminum foil, while aluminum excels in heat retention and reflective qualities.

Durability and Protection: Which Wrap Performs Better?

Mylar wrapping outperforms aluminum wrapping in durability due to its superior resistance to tearing, moisture, and UV radiation, ensuring long-lasting protection for stored items. Its multi-layer polyester composition provides an effective barrier against oxygen and contaminants, maintaining product freshness more reliably than aluminum foil. While aluminum offers decent protection, Mylar's enhanced flexibility and strength make it the preferred choice for extending shelf life and safeguarding sensitive materials.

Barrier Properties: Moisture, Oxygen, and Light Resistance

Mylar wrapping offers superior barrier properties compared to aluminum, providing exceptional resistance to moisture, oxygen, and light penetration. This high-performance polyester film ensures prolonged preservation of product freshness and integrity by minimizing exposure to environmental factors that cause degradation. Aluminum wrapping, while effective in blocking light and oxygen, is less flexible and moisture-resistant, making Mylar the preferred choice for packaging applications requiring enhanced barrier protection.

Flexibility and Ease of Use

Mylar wrapping offers superior flexibility compared to aluminum wrapping, allowing it to conform more easily to irregular shapes and contours. Its lightweight and pliable properties make Mylar easier to handle and manipulate during application. Aluminum wrapping, while durable, is stiffer and less adaptable, often requiring more effort to achieve a tight seal on complex surfaces.

Food Safety and Regulatory Compliance

Mylar wrapping provides superior food safety by creating an airtight, moisture-resistant barrier that preserves freshness and prevents contamination better than aluminum wrapping. Unlike aluminum, Mylar is non-reactive and complies with FDA regulations for food contact materials, reducing the risk of chemical leaching into food. Its compliance with food safety standards ensures reliable protection during storage and transportation.

Cost Analysis: Mylar Wrapping vs Aluminum Wrapping

Mylar wrapping typically offers a cost-effective solution compared to aluminum wrapping due to lower material and manufacturing expenses. While aluminum provides excellent heat reflection and durability, the lightweight nature and lower price point of Mylar reduce overall expenditure for large-scale applications. Evaluating long-term costs, Mylar's resistance to tearing and moisture can lower replacement frequency, enhancing its economic advantage over aluminum wrapping.

Environmental Impact and Recyclability

Mylar wrapping offers a lower environmental impact compared to aluminum wrapping due to its lightweight polyester composition, which requires less energy to produce and transport. Unlike aluminum foil, Mylar is more easily recyclable in facilities equipped to handle polyester films, reducing landfill waste. However, both materials have limitations in recycling availability, making the choice dependent on local recycling infrastructure and end-of-life disposal practices.

Common Applications in Packaging

Mylar wrapping is widely used for packaging electronics, food, and pharmaceuticals due to its excellent moisture barrier, high tensile strength, and clarity. Aluminum wrapping is common in food packaging, such as foil wraps for baked goods and meat products, because of its superior heat resistance and ability to block light and oxygen. Both materials excel in preserving freshness, but Mylar's flexibility and printability make it ideal for promotional packaging and multi-layered pouches.

Which Wrapping Should You Choose?

Mylar wrapping offers superior moisture and gas barrier properties compared to aluminum wrapping, making it ideal for long-term food storage and preservation of freshness. Aluminum wrapping excels at reflecting heat and light, which helps protect food from temperature fluctuations but is less effective against moisture penetration. Choosing Mylar wrapping is recommended when humidity control and airtight sealing are priorities, while aluminum wrapping suits applications requiring light and heat reflection.

Mylar Wrapping vs Aluminum Wrapping Infographic

materialdif.com

materialdif.com