Mylar offers superior durability and resistance to tearing compared to PVC, making it ideal for long-lasting pet products such as collars and tags. Its reflective surface provides enhanced visibility for pets in low-light conditions, promoting safety during nighttime walks. Unlike PVC, Mylar is more environmentally friendly due to its recyclability and lower chemical emissions during production.

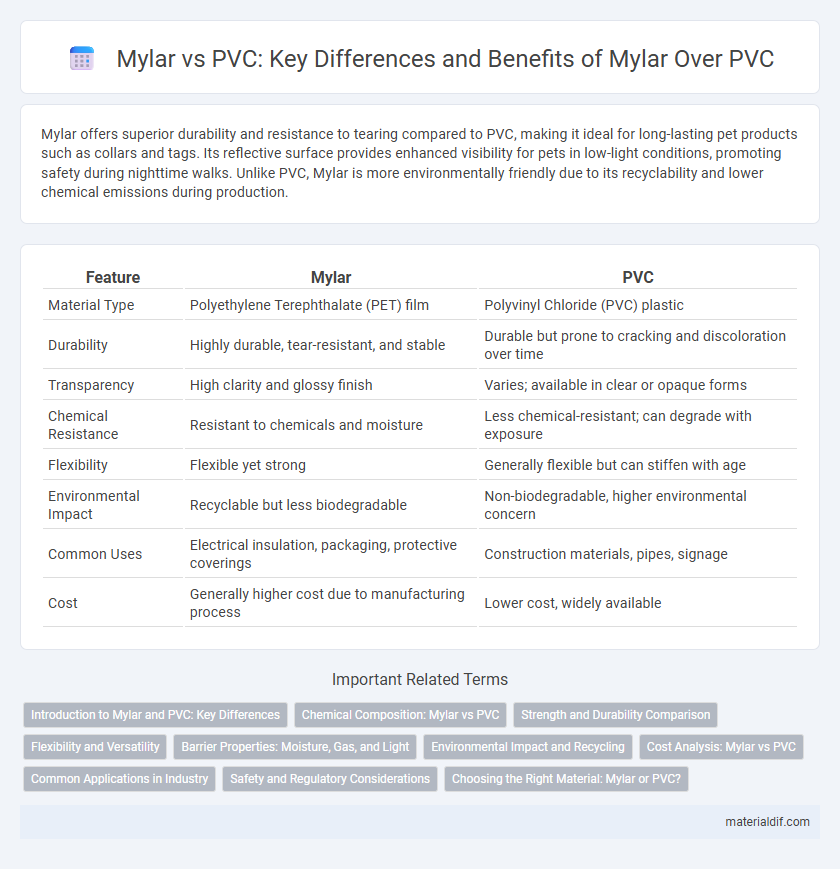

Table of Comparison

| Feature | Mylar | PVC |

|---|---|---|

| Material Type | Polyethylene Terephthalate (PET) film | Polyvinyl Chloride (PVC) plastic |

| Durability | Highly durable, tear-resistant, and stable | Durable but prone to cracking and discoloration over time |

| Transparency | High clarity and glossy finish | Varies; available in clear or opaque forms |

| Chemical Resistance | Resistant to chemicals and moisture | Less chemical-resistant; can degrade with exposure |

| Flexibility | Flexible yet strong | Generally flexible but can stiffen with age |

| Environmental Impact | Recyclable but less biodegradable | Non-biodegradable, higher environmental concern |

| Common Uses | Electrical insulation, packaging, protective coverings | Construction materials, pipes, signage |

| Cost | Generally higher cost due to manufacturing process | Lower cost, widely available |

Introduction to Mylar and PVC: Key Differences

Mylar is a biaxially-oriented polyethylene terephthalate (BoPET) film known for its exceptional tensile strength, chemical stability, and reflective properties, making it ideal for insulation, packaging, and electronics. PVC (polyvinyl chloride) is a versatile plastic commonly used in construction, medical devices, and signage due to its flexibility, durability, and resistance to environmental degradation. Unlike PVC, Mylar offers superior thermal resistance and lower permeability, whereas PVC provides better impact resistance and easier fabrication options.

Chemical Composition: Mylar vs PVC

Mylar is a polyester film primarily composed of polyethylene terephthalate (PET) known for its durable molecular structure and chemical stability. In contrast, PVC (polyvinyl chloride) consists of vinyl chloride monomers with chlorine atoms integrated into its composition, making it more susceptible to chemical degradation and release of harmful compounds. The distinct chemical compositions of Mylar and PVC influence their physical properties, environmental impact, and suitability for various industrial applications.

Strength and Durability Comparison

Mylar exhibits superior tensile strength and puncture resistance compared to PVC, making it more durable in demanding applications. Its resistance to chemical corrosion and UV radiation extends its lifespan significantly beyond PVC materials. This enhanced durability makes Mylar ideal for protective coverings, insulation, and long-term outdoor use.

Flexibility and Versatility

Mylar offers superior flexibility compared to PVC, making it ideal for applications requiring bending and repeated handling without damage. Its versatility extends across insulation, packaging, and printing industries due to its chemical stability and resistance to moisture. In contrast, PVC is more rigid and less adaptable, limiting its use where flexibility is crucial.

Barrier Properties: Moisture, Gas, and Light

Mylar exhibits superior barrier properties against moisture, gases, and light compared to PVC, making it ideal for packaging applications requiring extended shelf life and product protection. Its dense polyester film structure significantly reduces permeability, effectively preserving freshness and preventing contamination. In contrast, PVC's higher permeability limits its effectiveness in environments demanding stringent barrier performance.

Environmental Impact and Recycling

Mylar, a polyester film made from polyethylene terephthalate (PET), has a significantly lower environmental impact compared to polyvinyl chloride (PVC) due to its recyclability and reduced toxic emissions during production and disposal. Unlike PVC, which releases harmful dioxins and chlorine-based compounds when incinerated, Mylar can be recycled efficiently into new products without releasing hazardous substances. The biodegradable challenges of PVC and its persistent environmental pollutants make Mylar a more sustainable choice in packaging and industrial applications.

Cost Analysis: Mylar vs PVC

Mylar offers a higher initial cost compared to PVC but provides long-term savings due to its durability and resistance to environmental factors, reducing replacement frequency. PVC is generally cheaper upfront but may incur higher maintenance and replacement expenses over time because of its susceptibility to UV degradation and brittleness. Evaluating lifecycle costs highlights Mylar's cost-effectiveness for projects requiring longevity and minimal upkeep.

Common Applications in Industry

Mylar is extensively used in electronics for insulating films and flexible printed circuits, while PVC dominates in construction for pipes and window frames due to its rigidity. Mylar's superior tensile strength and chemical resistance make it ideal for packaging, solar reflectors, and magnetic media, contrasting with PVC's use in cables, flooring, and automotive interiors. Industries prefer Mylar when lightweight, high-performance barrier materials are essential, whereas PVC is favored for cost-effective, durable, and fire-resistant applications.

Safety and Regulatory Considerations

Mylar, a polyester film, offers superior safety by being non-toxic, chemically stable, and resistant to UV degradation, meeting stringent regulatory standards such as FDA and RoHS compliance. In contrast, PVC contains potentially harmful plasticizers and chlorine, raising concerns over toxic fume emission during manufacturing and disposal, which often conflicts with environmental regulations. Mylar's recyclability and reduced environmental impact further enhance its regulatory acceptance over PVC in applications demanding high safety standards.

Choosing the Right Material: Mylar or PVC?

Mylar offers superior tensile strength, chemical resistance, and clarity compared to PVC, making it ideal for durable, high-visibility applications such as packaging and insulation. PVC, while more flexible and cost-effective, often lacks the long-term durability and environmental resistance of Mylar. Selecting between Mylar and PVC depends on the specific requirements for strength, flexibility, and exposure conditions in your project.

Mylar vs PVC Infographic

materialdif.com

materialdif.com