Mylar film offers superior tensile strength and chemical resistance compared to polycarbonate film, making it ideal for applications requiring durability and stability under harsh conditions. Polycarbonate film, known for its exceptional impact resistance and optical clarity, excels in protective layers and transparent components where flexibility and toughness are essential. Both films provide unique benefits, but Mylar's heat resistance and electrical insulation properties make it the preferred choice in electronics and insulation industries.

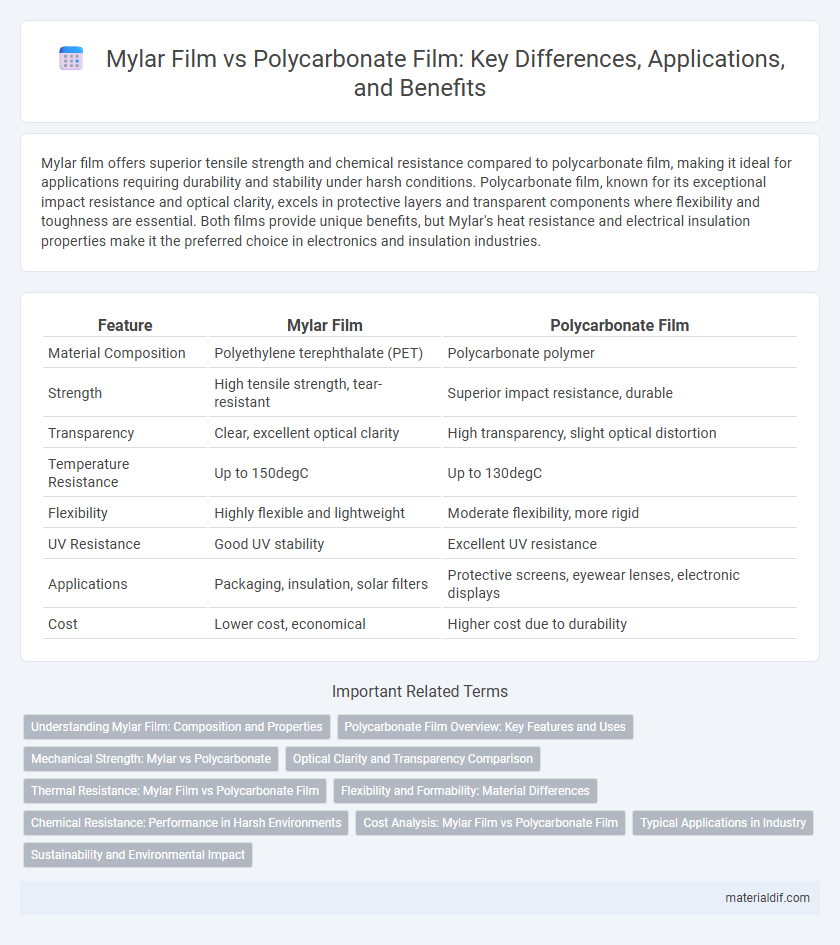

Table of Comparison

| Feature | Mylar Film | Polycarbonate Film |

|---|---|---|

| Material Composition | Polyethylene terephthalate (PET) | Polycarbonate polymer |

| Strength | High tensile strength, tear-resistant | Superior impact resistance, durable |

| Transparency | Clear, excellent optical clarity | High transparency, slight optical distortion |

| Temperature Resistance | Up to 150degC | Up to 130degC |

| Flexibility | Highly flexible and lightweight | Moderate flexibility, more rigid |

| UV Resistance | Good UV stability | Excellent UV resistance |

| Applications | Packaging, insulation, solar filters | Protective screens, eyewear lenses, electronic displays |

| Cost | Lower cost, economical | Higher cost due to durability |

Understanding Mylar Film: Composition and Properties

Mylar film, composed primarily of biaxially-oriented polyethylene terephthalate (BoPET), offers exceptional tensile strength, chemical stability, and thermal resistance, making it ideal for insulation and packaging applications. In contrast, polycarbonate film is a thermoplastic polymer known for impact resistance and optical clarity but lacks Mylar's superior dimensional stability and chemical inertness. Understanding Mylar's polyester base explains its unique durability, moisture barrier properties, and electrical insulation capabilities compared to polycarbonate alternatives.

Polycarbonate Film Overview: Key Features and Uses

Polycarbonate film offers exceptional impact resistance, high optical clarity, and superior thermal stability, making it ideal for applications requiring durability and transparency. Commonly used in electronic displays, automotive glazing, and protective eyewear, its ability to withstand harsh environmental conditions ensures long-term performance. Unlike Mylar film, polycarbonate film provides enhanced toughness and resistance to scratching, expanding its use in more demanding industrial and consumer products.

Mechanical Strength: Mylar vs Polycarbonate

Mylar film exhibits excellent tensile strength and dimensional stability, making it highly resistant to stretching and tearing under mechanical stress. Polycarbonate film offers superior impact resistance and higher toughness, providing greater durability against bending and impact forces. Choosing between Mylar and polycarbonate films depends on whether tensile strength or impact resilience is the primary mechanical requirement.

Optical Clarity and Transparency Comparison

Mylar film offers exceptional optical clarity with a high degree of transparency, making it ideal for applications requiring clear, distortion-free viewing. Polycarbonate film, while durable and impact-resistant, typically exhibits slightly lower transparency and can have a subtle haze under certain lighting conditions. Choosing between Mylar and polycarbonate films depends on the priority of optical performance versus mechanical toughness in the intended use.

Thermal Resistance: Mylar Film vs Polycarbonate Film

Mylar film exhibits superior thermal resistance with a continuous operating temperature up to 150degC, making it ideal for high-heat applications. Polycarbonate film typically withstands temperatures up to 125degC but tends to degrade faster under prolonged thermal stress. This makes Mylar film a more reliable choice for environments requiring consistent high-temperature performance.

Flexibility and Formability: Material Differences

Mylar film offers superior flexibility and exceptional formability due to its polyester composition, allowing it to bend and stretch without cracking, making it ideal for applications requiring durable, flexible materials. In contrast, polycarbonate film is more rigid and impact-resistant but less flexible, providing excellent structural strength while limiting formability for complex shapes. The choice between Mylar and polycarbonate films hinges on the need for either enhanced flexibility or higher impact resistance in demanding product designs.

Chemical Resistance: Performance in Harsh Environments

Mylar film exhibits superior chemical resistance compared to polycarbonate film, making it highly effective in harsh environments involving exposure to solvents, acids, and alkaline substances. Its polyester composition allows Mylar to maintain structural integrity and clarity without degradation, whereas polycarbonate films often suffer from swelling, cracking, or discoloration under similar chemical attacks. This resistance to chemical damage makes Mylar the preferred choice for applications requiring long-term durability and stable performance in aggressive chemical settings.

Cost Analysis: Mylar Film vs Polycarbonate Film

Mylar film generally costs less than polycarbonate film, making it a more budget-friendly option for applications requiring good tensile strength and chemical resistance. Polycarbonate film, while more expensive, offers superior impact resistance and optical clarity, which can justify the higher price for high-performance uses. Cost analysis should weigh initial investment against durability and specific application needs to determine the most economical choice.

Typical Applications in Industry

Mylar film is widely used in electrical insulation, packaging, and flexible printed circuits due to its excellent dielectric strength, chemical resistance, and dimensional stability. Polycarbonate film is preferred in automotive glazing, optical lenses, and impact-resistant applications because of its high impact resistance, transparency, and thermal stability. Both films serve critical roles in electronics and packaging industries, but Mylar excels in insulation and barrier properties while polycarbonate dominates in structural and optical uses.

Sustainability and Environmental Impact

Mylar film, made from biaxially-oriented polyethylene terephthalate (BoPET), offers superior recyclability and lower carbon footprint compared to polycarbonate film, which is derived from bisphenol-A (BPA) and exhibits more challenging recycling processes. Mylar's durability and resistance to chemicals extend product lifespan, reducing waste accumulation in landfills. Polycarbonate film, while tough and impact-resistant, tends to release harmful substances during production and disposal, raising environmental concerns.

Mylar Film vs Polycarbonate Film Infographic

materialdif.com

materialdif.com