Anti-static Mylar is designed to prevent the buildup of static electricity, making it ideal for protecting sensitive electronic components from electrostatic discharge without conducting electricity. Conductive Mylar, on the other hand, contains conductive materials that allow it to dissipate static charges by providing a path for electrical conductivity, often used in applications requiring electromagnetic interference shielding. Choosing between anti-static and conductive Mylar depends on whether you need to merely prevent static buildup or actively conduct and dissipate electrical charges in your packaging or protective solution.

Table of Comparison

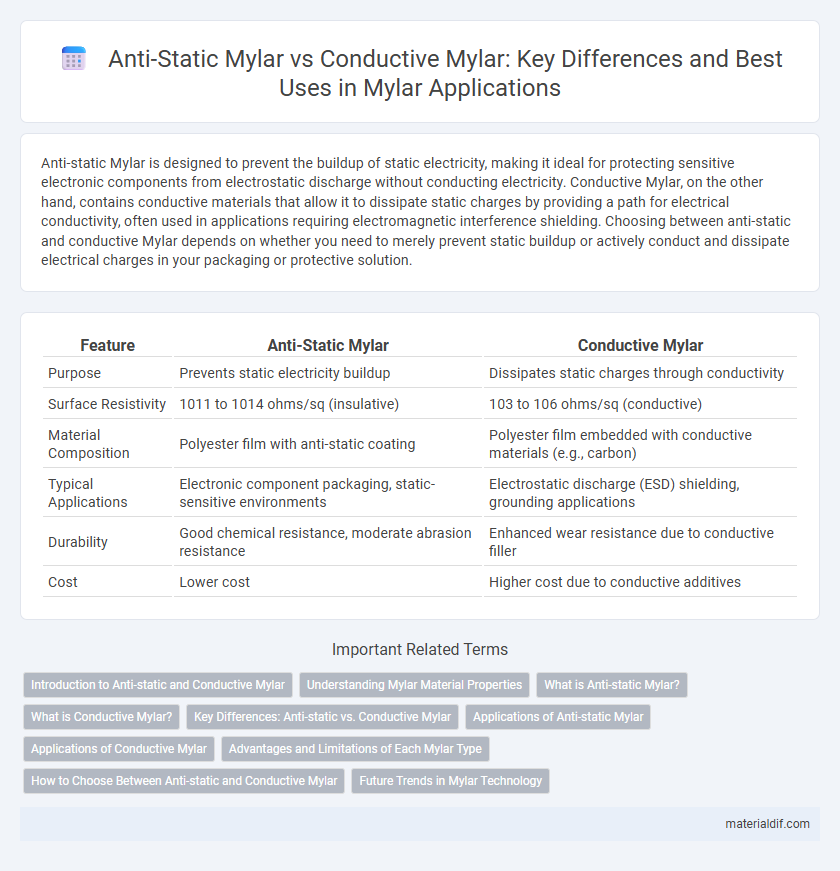

| Feature | Anti-Static Mylar | Conductive Mylar |

|---|---|---|

| Purpose | Prevents static electricity buildup | Dissipates static charges through conductivity |

| Surface Resistivity | 1011 to 1014 ohms/sq (insulative) | 103 to 106 ohms/sq (conductive) |

| Material Composition | Polyester film with anti-static coating | Polyester film embedded with conductive materials (e.g., carbon) |

| Typical Applications | Electronic component packaging, static-sensitive environments | Electrostatic discharge (ESD) shielding, grounding applications |

| Durability | Good chemical resistance, moderate abrasion resistance | Enhanced wear resistance due to conductive filler |

| Cost | Lower cost | Higher cost due to conductive additives |

Introduction to Anti-static and Conductive Mylar

Anti-static Mylar is engineered to prevent the buildup of static electricity by dissipating low levels of electrical charge, making it ideal for packaging sensitive electronic components. Conductive Mylar contains embedded conductive materials that provide a low-resistance path for electrical discharge, offering enhanced protection against electrostatic discharge (ESD) in more demanding environments. Both variants serve critical roles in safeguarding electronics, with anti-static Mylar suited for minimal static control and conductive Mylar designed for robust ESD shielding.

Understanding Mylar Material Properties

Anti-static Mylar is engineered to resist static electricity by incorporating a surface coating that prevents charge buildup, making it ideal for protecting sensitive electronic components. Conductive Mylar, on the other hand, contains embedded conductive particles or metalized layers that allow it to dissipate static charges quickly, providing effective shielding against electromagnetic interference. Understanding the differences in electrical conductivity and surface resistivity between anti-static and conductive Mylar is crucial for selecting the appropriate material in electronics packaging and static control applications.

What is Anti-static Mylar?

Anti-static Mylar is a specially treated polyester film designed to reduce static electricity buildup, protecting sensitive electronic components from electrostatic discharge (ESD). Unlike conductive Mylar, which actively dissipates charge through electrical conductivity, anti-static Mylar provides a controlled surface resistivity that prevents static charge accumulation without conducting electricity. This makes anti-static Mylar ideal for packaging and handling delicate electronics where static prevention is critical but conductivity could cause damage.

What is Conductive Mylar?

Conductive Mylar is a specially coated polyester film designed to dissipate static electricity by allowing electrical charges to flow through its surface. It incorporates a thin layer of conductive material, such as carbon or metal, enabling it to prevent static buildup and protect sensitive electronic components. This type of Mylar is essential in environments where electrostatic discharge (ESD) could damage devices or interfere with their operation.

Key Differences: Anti-static vs. Conductive Mylar

Anti-static Mylar is designed to prevent static charge buildup by dissipating surface charges, making it ideal for protecting sensitive electronic components from electrostatic discharge. Conductive Mylar, on the other hand, contains conductive materials that allow electrical current to flow through the material, providing shielding against electromagnetic interference (EMI) and radio-frequency interference (RFI). The key difference lies in their function: anti-static Mylar reduces static electricity without conductivity, while conductive Mylar offers both static protection and electrical conductivity for advanced shielding applications.

Applications of Anti-static Mylar

Anti-static Mylar is widely used in electronics packaging to prevent static discharge that can damage sensitive components, making it ideal for storing semiconductors, circuit boards, and other electronic devices. Its non-conductive properties ensure that static electricity is dissipated without creating a short circuit, which is critical in cleanroom environments and manufacturing processes. Common applications include protective bags, covers, and linings for electronics assembly and transport.

Applications of Conductive Mylar

Conductive Mylar is widely used in electronic packaging and shielding due to its ability to dissipate static electricity and protect sensitive components from electromagnetic interference (EMI). Its applications extend to flexible printed circuits, touchscreens, and antistatic bags in the semiconductor industry, where maintaining signal integrity is crucial. The material's exceptional conductivity and durability make it ideal for use in environments requiring reliable electrostatic discharge (ESD) protection and EMI shielding.

Advantages and Limitations of Each Mylar Type

Anti-static Mylar offers excellent protection against electrostatic discharge without conducting electricity, making it ideal for sensitive electronic components and preventing dust attraction. Conductive Mylar provides superior shielding against electromagnetic interference through its ability to dissipate static charges, but it may cause grounding issues in delicate circuitry. Choosing between Anti-static and Conductive Mylar depends on balancing static protection needs with conductivity requirements in specific applications.

How to Choose Between Anti-static and Conductive Mylar

Choosing between anti-static Mylar and conductive Mylar depends on the specific electrostatic discharge (ESD) protection requirements of your application. Anti-static Mylar provides a low-resistance surface that prevents static build-up by dissipating charges slowly, ideal for protecting sensitive electronic components during handling and storage. Conductive Mylar offers a much lower resistance to ground charges rapidly, suitable for environments requiring fast discharge of static electricity to avoid damage from sudden ESD events.

Future Trends in Mylar Technology

Future trends in Mylar technology highlight advancements in anti-static and conductive variants, emphasizing improved electrical properties and enhanced durability. Innovations include integrating nano-coatings to boost conductivity and reduce static buildup, catering to electronics and packaging industries. Research focuses on sustainable Mylar formulations, balancing performance with environmental impact for next-generation applications.

Anti-static Mylar vs Conductive Mylar Infographic

materialdif.com

materialdif.com