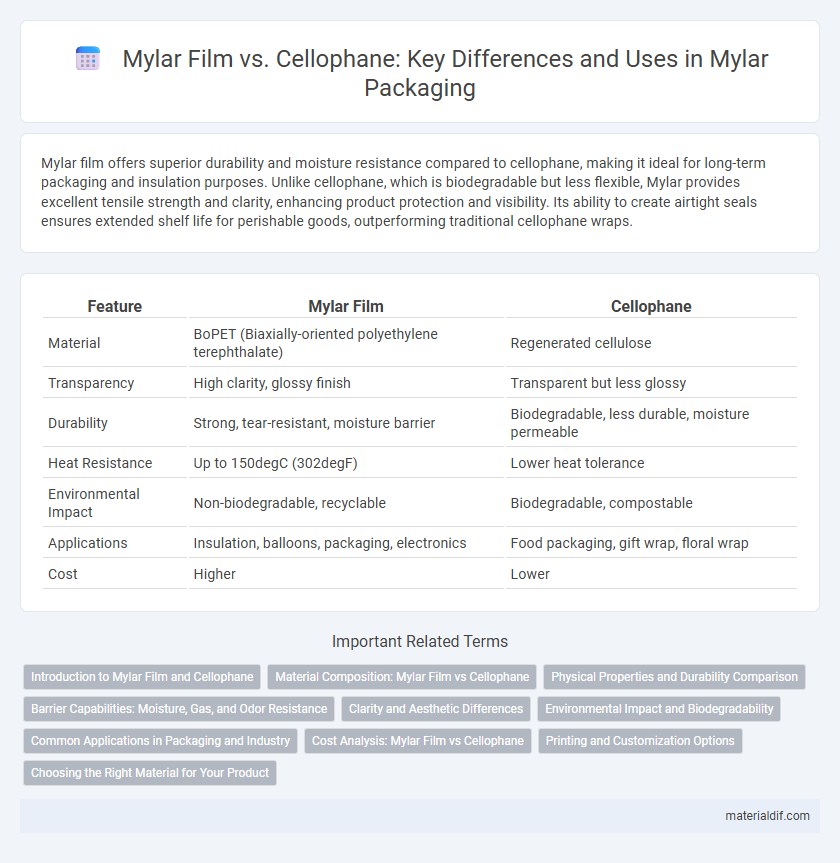

Mylar film offers superior durability and moisture resistance compared to cellophane, making it ideal for long-term packaging and insulation purposes. Unlike cellophane, which is biodegradable but less flexible, Mylar provides excellent tensile strength and clarity, enhancing product protection and visibility. Its ability to create airtight seals ensures extended shelf life for perishable goods, outperforming traditional cellophane wraps.

Table of Comparison

| Feature | Mylar Film | Cellophane |

|---|---|---|

| Material | BoPET (Biaxially-oriented polyethylene terephthalate) | Regenerated cellulose |

| Transparency | High clarity, glossy finish | Transparent but less glossy |

| Durability | Strong, tear-resistant, moisture barrier | Biodegradable, less durable, moisture permeable |

| Heat Resistance | Up to 150degC (302degF) | Lower heat tolerance |

| Environmental Impact | Non-biodegradable, recyclable | Biodegradable, compostable |

| Applications | Insulation, balloons, packaging, electronics | Food packaging, gift wrap, floral wrap |

| Cost | Higher | Lower |

Introduction to Mylar Film and Cellophane

Mylar film is a polyester resin film known for its strength, chemical stability, and excellent electrical insulation properties, widely used in packaging, insulation, and graphics. Cellophane, derived from cellulose, is a biodegradable film that offers breathability and clarity, primarily used for food wrapping and decorative purposes. While Mylar provides superior durability and moisture resistance, cellophane is favored for its eco-friendly and compostable characteristics.

Material Composition: Mylar Film vs Cellophane

Mylar film is made from stretched polyethylene terephthalate (PET), which provides superior tensile strength, chemical resistance, and dimensional stability, making it ideal for industrial and packaging applications. In contrast, cellophane is derived from cellulose, a natural polymer obtained from wood pulp or cotton, offering biodegradability but lower water and chemical resistance compared to Mylar. The synthetic polyester base of Mylar gives it enhanced durability and moisture barrier properties, while cellophane's organic composition favors eco-friendly disposability.

Physical Properties and Durability Comparison

Mylar film is composed of stretched polyethylene terephthalate (PET), offering superior tensile strength, dimensional stability, and resistance to moisture and gases compared to cellophane, which is derived from cellulose and tends to be more permeable and less durable. Mylar exhibits high clarity, excellent thermal resistance up to 150degC, and exceptional resistance to tearing and punctures, while cellophane is prone to brittleness and degradation in humid environments. These physical properties make Mylar the preferred choice for long-lasting packaging, insulation, and protective applications where enhanced durability and barrier performance are critical.

Barrier Capabilities: Moisture, Gas, and Odor Resistance

Mylar film exhibits superior barrier capabilities compared to cellophane, providing exceptional resistance to moisture, gases, and odors. Its polyester base structure creates a dense, non-porous layer that effectively reduces water vapor transmission rates and oxygen permeability. In contrast, cellophane's cellulose composition offers limited protection against moisture and gases, making Mylar the preferred choice for packaging applications requiring prolonged freshness and contamination prevention.

Clarity and Aesthetic Differences

Mylar film exhibits superior clarity with a glossy, reflective surface that enhances color vibrancy and sharpness, making it ideal for high-quality packaging and decorative applications. Cellophane, being more matte and prone to haziness, provides a softer, less vibrant appearance but offers a natural, biodegradable aesthetic favored in eco-friendly packaging. The distinct optical properties of Mylar film result in a sleek, modern look, while cellophane's translucency lends a rustic, organic charm.

Environmental Impact and Biodegradability

Mylar film, made from polyethylene terephthalate (PET), is known for its durability and resistance to moisture but is not biodegradable, contributing to long-term environmental waste. In contrast, cellophane is derived from regenerated cellulose, making it biodegradable and compostable, which significantly reduces its ecological footprint. While Mylar offers superior physical properties, its environmental impact is higher compared to the eco-friendlier biodegradability of cellophane.

Common Applications in Packaging and Industry

Mylar film excels in packaging and industrial applications due to its superior tensile strength, chemical resistance, and moisture barrier properties, making it ideal for food packaging, insulation, and protective covers. Cellophane, primarily used for its biodegradability and clarity, is favored in wrapping fresh produce, confectionery, and floral packaging. Industries often prefer Mylar for long-term durability and heat resistance, while cellophane suits short-term or eco-friendly packaging needs.

Cost Analysis: Mylar Film vs Cellophane

Mylar film typically costs more upfront than cellophane due to its complex polyester composition and superior durability. Despite the higher initial price, Mylar's longevity and resistance to moisture and chemicals often result in lower replacement and maintenance expenses over time. Cellophane remains a cost-effective option for short-term applications but may incur higher costs related to frequent replacement and limited protective qualities.

Printing and Customization Options

Mylar film offers superior printing capabilities compared to cellophane, supporting high-resolution graphics and vibrant color reproduction due to its polyester composition. Unlike cellophane, Mylar allows for advanced customization techniques such as UV coating, embossing, and metallic finishes, enhancing product appeal and durability. These features make Mylar the preferred choice for premium packaging and labels requiring detailed artwork and long-lasting visuals.

Choosing the Right Material for Your Product

Mylar film offers superior tensile strength, moisture resistance, and heat insulation compared to cellophane, making it ideal for packaging sensitive electronics, food, and insulation products. Cellophane excels in biodegradability and clarity but lacks the durability and barrier properties needed for long-term protection. Selecting the right material depends on product requirements such as shelf life, environmental impact, and mechanical protection.

Mylar Film vs Cellophane Infographic

materialdif.com

materialdif.com