Mylar barrier offers superior moisture and oxygen resistance compared to aluminum foil barrier, making it ideal for long-term food storage and pet treat preservation. Its lightweight and tear-resistant properties provide enhanced durability without compromising flexibility, unlike the more brittle aluminum foil. Mylar also maintains airtight seals better, ensuring freshness and extending the shelf life of pet products effectively.

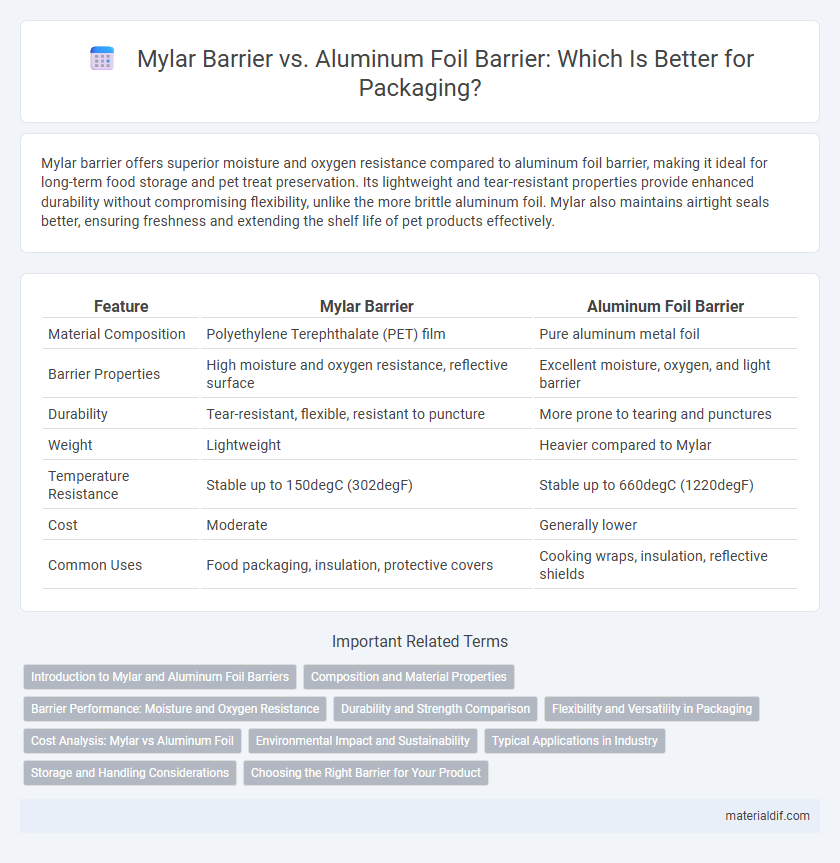

Table of Comparison

| Feature | Mylar Barrier | Aluminum Foil Barrier |

|---|---|---|

| Material Composition | Polyethylene Terephthalate (PET) film | Pure aluminum metal foil |

| Barrier Properties | High moisture and oxygen resistance, reflective surface | Excellent moisture, oxygen, and light barrier |

| Durability | Tear-resistant, flexible, resistant to puncture | More prone to tearing and punctures |

| Weight | Lightweight | Heavier compared to Mylar |

| Temperature Resistance | Stable up to 150degC (302degF) | Stable up to 660degC (1220degF) |

| Cost | Moderate | Generally lower |

| Common Uses | Food packaging, insulation, protective covers | Cooking wraps, insulation, reflective shields |

Introduction to Mylar and Aluminum Foil Barriers

Mylar barrier consists of a polyester film known for its superior tensile strength, chemical stability, and reflective properties, making it ideal for insulation and packaging applications. Aluminum foil barrier features a thin layer of aluminum that offers excellent moisture, oxygen, and light resistance, commonly used in food and pharmaceutical packaging. While both barriers protect contents from environmental factors, Mylar provides enhanced durability and flexibility compared to the more rigid and conductive aluminum foil.

Composition and Material Properties

Mylar barrier consists of biaxially-oriented polyethylene terephthalate (BoPET), offering superior tensile strength, chemical stability, and thermal resistance compared to aluminum foil, which is made from a thin sheet of pure aluminum known for excellent reflectivity and moisture barrier properties. Unlike aluminum foil, Mylar provides enhanced puncture resistance and dimensional stability, making it ideal for long-term packaging and insulation applications. Both materials provide effective barriers against light, oxygen, and moisture, but Mylar's polymer composition results in greater flexibility and durability in various environmental conditions.

Barrier Performance: Moisture and Oxygen Resistance

Mylar barrier films provide superior moisture and oxygen resistance compared to aluminum foil barriers, ensuring enhanced protection for sensitive products. The multilayer polyester structure of Mylar offers excellent dimensional stability and durability, maintaining barrier integrity under varying environmental conditions. Unlike aluminum foil, which can puncture or degrade over time, Mylar sustains consistent barrier performance, crucial for extended shelf-life applications in food and pharmaceuticals.

Durability and Strength Comparison

Mylar barriers exhibit superior durability and tensile strength compared to aluminum foil barriers, making them more resistant to tearing and punctures. The polyester base in Mylar provides enhanced flexibility and longevity under varying environmental conditions, whereas aluminum foil tends to degrade and crack over time. These characteristics make Mylar a preferred choice for applications requiring long-lasting and robust barrier protection.

Flexibility and Versatility in Packaging

Mylar barrier films offer superior flexibility and versatility in packaging compared to aluminum foil barriers, adapting easily to various shapes and sizes without compromising durability. Unlike aluminum foil, Mylar maintains structural integrity under bending and folding, making it ideal for flexible packaging applications such as pouches and wraps. Its ability to be metallized or laminated enhances barrier properties while allowing for customization in packaging design.

Cost Analysis: Mylar vs Aluminum Foil

Mylar offers a cost-effective alternative to aluminum foil in barrier applications due to its lower material and manufacturing expenses. While aluminum foil provides excellent barrier properties against moisture and oxygen, its higher production and recycling costs often make Mylar more economical for large-scale usage. The versatility and durability of Mylar reduce replacement frequency, further enhancing cost savings compared to aluminum foil barriers.

Environmental Impact and Sustainability

Mylar barrier offers superior environmental benefits compared to aluminum foil barrier due to its lightweight nature and lower energy consumption during production, resulting in reduced carbon emissions. Unlike aluminum foil, which relies on mining and extensive energy processes, Mylar is recyclable and often made from PET, enhancing sustainability and waste reduction efforts. The durability and reuse potential of Mylar further minimize environmental impact, positioning it as a more eco-friendly choice in packaging and insulation applications.

Typical Applications in Industry

Mylar barriers are widely used in electronics and packaging industries for insulation and moisture protection due to their high tensile strength and clarity, while aluminum foil barriers excel in food packaging and pharmaceutical applications because of their superior oxygen and light impermeability. The flexibility and reflective properties of Mylar make it ideal for thermal insulation and decorative purposes, whereas aluminum foil's excellent barrier against contaminants is preferred in vacuum sealing and cryogenic applications. Both materials serve crucial roles but are selected based on specific barrier requirements and environmental exposure in industrial processes.

Storage and Handling Considerations

Mylar barriers offer superior flexibility and tear resistance compared to aluminum foil barriers, making them easier to handle and less prone to damage during storage. Unlike aluminum foil, Mylar is moisture-resistant and does not corrode, ensuring better long-term preservation of sensitive items in various environmental conditions. Storage requirements for Mylar involve keeping it in a cool, dry place away from direct sunlight to maintain its barrier integrity and extend shelf life.

Choosing the Right Barrier for Your Product

Mylar barriers provide superior moisture and oxygen resistance compared to aluminum foil, making them ideal for products requiring extended shelf life. Aluminum foil offers excellent light and odor blocking properties, but it is more prone to punctures and less flexible for packaging applications. Selecting the right barrier depends on the product's sensitivity to environmental factors, desired durability, and packaging requirements.

Mylar Barrier vs Aluminum Foil Barrier Infographic

materialdif.com

materialdif.com