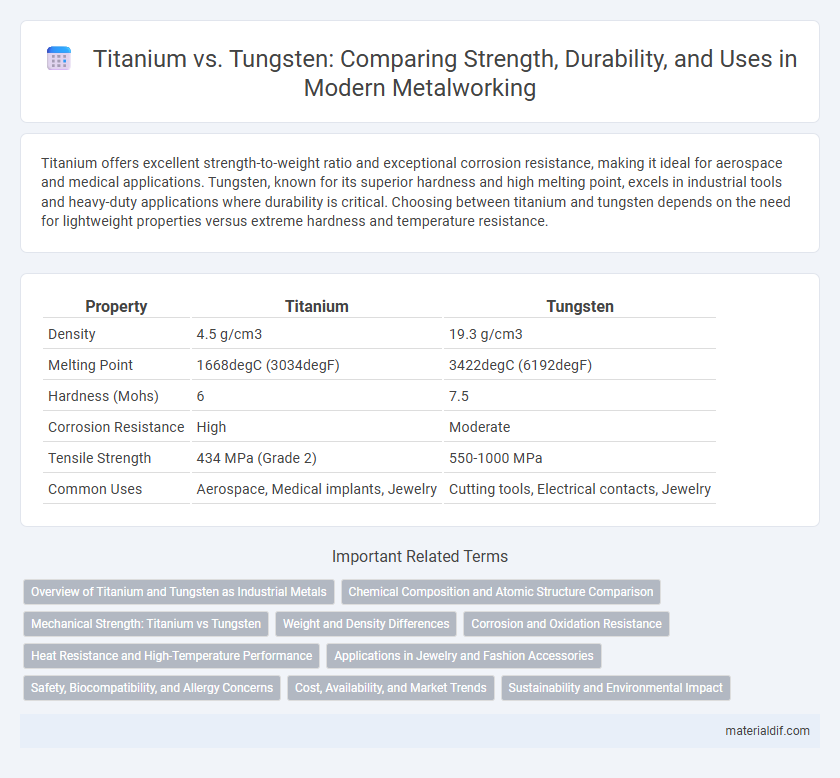

Titanium offers excellent strength-to-weight ratio and exceptional corrosion resistance, making it ideal for aerospace and medical applications. Tungsten, known for its superior hardness and high melting point, excels in industrial tools and heavy-duty applications where durability is critical. Choosing between titanium and tungsten depends on the need for lightweight properties versus extreme hardness and temperature resistance.

Table of Comparison

| Property | Titanium | Tungsten |

|---|---|---|

| Density | 4.5 g/cm3 | 19.3 g/cm3 |

| Melting Point | 1668degC (3034degF) | 3422degC (6192degF) |

| Hardness (Mohs) | 6 | 7.5 |

| Corrosion Resistance | High | Moderate |

| Tensile Strength | 434 MPa (Grade 2) | 550-1000 MPa |

| Common Uses | Aerospace, Medical implants, Jewelry | Cutting tools, Electrical contacts, Jewelry |

Overview of Titanium and Tungsten as Industrial Metals

Titanium is a lightweight, corrosion-resistant metal widely used in aerospace, medical implants, and automotive industries due to its high strength-to-weight ratio and excellent biocompatibility. Tungsten is known for its exceptional hardness, high melting point, and density, making it essential in applications requiring durability and heat resistance, such as cutting tools, electrical contacts, and military armor. Both metals play crucial industrial roles, with titanium favored for weight-sensitive applications and tungsten preferred for wear resistance and thermal stability.

Chemical Composition and Atomic Structure Comparison

Titanium features an atomic number of 22 with an electron configuration of [Ar] 3d2 4s2, characterized by its hexagonal close-packed (hcp) crystal structure at room temperature, enhancing its strength and corrosion resistance. Tungsten, with an atomic number of 74 and electron configuration [Xe] 4f14 5d4 6s2, exhibits a body-centered cubic (bcc) crystal structure, providing exceptional hardness and a high melting point. The distinct atomic arrangements and electron configurations of titanium and tungsten directly influence their chemical reactivity, density, and industrial applications.

Mechanical Strength: Titanium vs Tungsten

Tungsten exhibits superior mechanical strength compared to titanium, with a tensile strength reaching up to 1510 MPa, while titanium typically ranges between 434 to 1400 MPa depending on the alloy. Tungsten's high melting point of 3422degC contributes to its exceptional hardness and durability under extreme conditions, making it ideal for applications requiring resistance to deformation and wear. Titanium offers a unique balance of strength and lightweight properties, with a density of 4.5 g/cm3 compared to tungsten's 19.3 g/cm3, providing strength-to-weight advantages in aerospace and medical industries.

Weight and Density Differences

Titanium has a density of approximately 4.5 grams per cubic centimeter, significantly lighter than tungsten's density of about 19.3 grams per cubic centimeter, making titanium more suitable for applications requiring reduced weight. Despite its lower density, titanium maintains excellent strength-to-weight ratio, whereas tungsten's high density contributes to superior hardness and durability but adds substantial weight. The weight difference plays a crucial role in aerospace and medical industries where minimizing mass is critical, favoring titanium over tungsten in lightweight structural components.

Corrosion and Oxidation Resistance

Titanium exhibits superior corrosion resistance due to its stable oxide layer, which protects it from rust and oxidation in various environments, including seawater and acidic conditions. Tungsten, while highly resistant to oxidation at elevated temperatures, is more susceptible to corrosion in acidic and alkaline environments compared to titanium. This makes titanium the preferred choice for applications requiring long-term durability in harsh chemical and marine settings.

Heat Resistance and High-Temperature Performance

Titanium exhibits excellent heat resistance with a melting point of approximately 1,668degC, making it suitable for high-temperature applications in aerospace and automotive industries. Tungsten outperforms titanium with an extraordinary melting point of 3,422degC, providing superior thermal stability and longevity in extreme environments such as industrial furnaces and rocket engine components. Both metals excel in high-temperature performance, but tungsten's resilience makes it ideal for conditions requiring extreme heat endurance.

Applications in Jewelry and Fashion Accessories

Titanium's lightweight, corrosion resistance, and hypoallergenic properties make it ideal for fashion jewelry, especially for everyday wear and active lifestyles. Tungsten's exceptional hardness and scratch resistance lend durability and a high-polish finish, favored in men's wedding bands and statement accessories. Both metals offer modern alternatives to traditional precious metals, providing distinct advantages in style and performance.

Safety, Biocompatibility, and Allergy Concerns

Titanium exhibits superior biocompatibility and is widely recognized for its hypoallergenic properties, making it a preferred choice in medical implants and jewelry for individuals with metal sensitivities. Tungsten, while extremely durable and scratch-resistant, may pose allergy concerns due to potential impurities and is less commonly used in direct skin contact applications. Safety considerations favor titanium because of its non-toxic nature and resistance to corrosion, reducing the risk of adverse reactions compared to tungsten alloys.

Cost, Availability, and Market Trends

Titanium is generally more expensive than tungsten due to its complex extraction and processing methods, despite both metals being relatively abundant in the Earth's crust. Tungsten boasts higher availability and lower cost, making it a preferred choice in industrial applications where durability and hardness are critical. Market trends show rising demand for titanium in aerospace and medical sectors, while tungsten remains dominant in heavy machinery and electronics due to its cost efficiency and high melting point.

Sustainability and Environmental Impact

Titanium offers superior sustainability due to its abundant natural reserves and recyclability, producing less environmental pollution during extraction compared to tungsten. Tungsten mining involves more energy-intensive processes and generates higher levels of toxic waste, contributing to greater ecological disruption. Titanium's lower carbon footprint and biocompatible properties make it a greener choice for environmentally conscious applications.

Titanium vs Tungsten Infographic

materialdif.com

materialdif.com