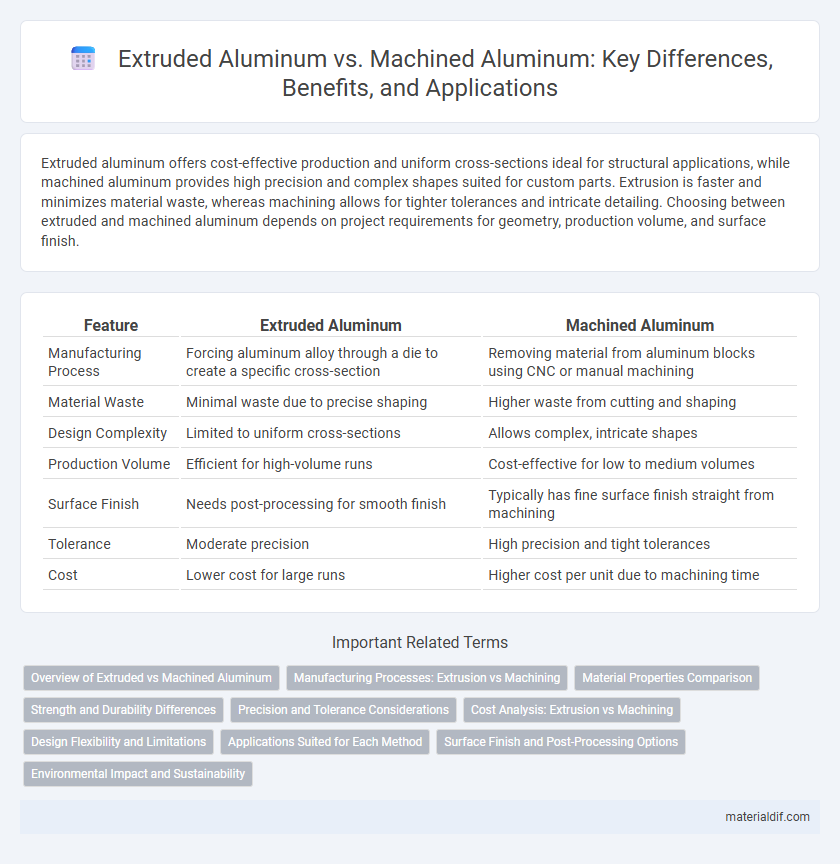

Extruded aluminum offers cost-effective production and uniform cross-sections ideal for structural applications, while machined aluminum provides high precision and complex shapes suited for custom parts. Extrusion is faster and minimizes material waste, whereas machining allows for tighter tolerances and intricate detailing. Choosing between extruded and machined aluminum depends on project requirements for geometry, production volume, and surface finish.

Table of Comparison

| Feature | Extruded Aluminum | Machined Aluminum |

|---|---|---|

| Manufacturing Process | Forcing aluminum alloy through a die to create a specific cross-section | Removing material from aluminum blocks using CNC or manual machining |

| Material Waste | Minimal waste due to precise shaping | Higher waste from cutting and shaping |

| Design Complexity | Limited to uniform cross-sections | Allows complex, intricate shapes |

| Production Volume | Efficient for high-volume runs | Cost-effective for low to medium volumes |

| Surface Finish | Needs post-processing for smooth finish | Typically has fine surface finish straight from machining |

| Tolerance | Moderate precision | High precision and tight tolerances |

| Cost | Lower cost for large runs | Higher cost per unit due to machining time |

Overview of Extruded vs Machined Aluminum

Extruded aluminum features a continuous profile created by forcing aluminum alloy through a shaped die, resulting in strong, lightweight components ideal for structural applications. Machined aluminum involves cutting, drilling, or milling a solid aluminum billet to achieve precise dimensions and complex geometries, offering high accuracy and surface finish. While extrusion excels in producing uniform cross-sections efficiently, machining provides flexibility for intricate designs and tight tolerances.

Manufacturing Processes: Extrusion vs Machining

Extruded aluminum involves forcing aluminum billets through a shaped die to create continuous profiles with uniform cross-sections, enabling high-volume production and minimal waste. Machined aluminum starts with solid billets or blocks and removes material using CNC tools, offering precise, complex shapes but often resulting in higher material waste and longer production times. The extrusion process is ideal for producing consistent, linear components, while machining excels in crafting customized, intricate parts with tight tolerances.

Material Properties Comparison

Extruded aluminum features a uniform grain structure aligned along the extrusion direction, resulting in enhanced strength and improved corrosion resistance compared to machined aluminum, which may have disrupted grain patterns due to cutting processes. Machined aluminum allows for higher dimensional precision and smoother surface finishes but can experience localized stress concentrations and potential microstructural changes. Both materials exhibit excellent thermal conductivity and lightweight characteristics, with extruded aluminum preferred for structural applications requiring higher strength-to-weight ratios.

Strength and Durability Differences

Extruded aluminum exhibits enhanced strength due to its continuous grain flow structure, which improves resistance to impact and fatigue compared to machined aluminum. Machined aluminum, while precise in dimensions, may have weakened areas where the grain flow is interrupted by cutting processes, potentially reducing overall durability. For applications requiring superior toughness and long-term performance, extruded aluminum is generally preferred over machined aluminum.

Precision and Tolerance Considerations

Extruded aluminum offers consistent cross-sectional profiles ideal for applications requiring uniformity but has limitations in achieving tight tolerances compared to machined aluminum. Machined aluminum allows for higher precision with complex geometries and tighter tolerances down to +-0.001 inches or better, essential for aerospace and medical components. Selecting between extruded and machined aluminum depends on the specific precision and tolerance requirements of the project.

Cost Analysis: Extrusion vs Machining

Extruded aluminum typically offers a lower cost per unit due to its efficient continuous production process, reducing material waste and labor expenses compared to machined aluminum. Machined aluminum incurs higher costs because of increased cutting time, tooling wear, and material removal, especially for complex or low-volume parts. Choosing extrusion over machining can lead to significant cost savings in projects requiring uniform cross-sectional profiles and high production volumes.

Design Flexibility and Limitations

Extruded aluminum offers superior design flexibility with its ability to create complex cross-sectional profiles and long lengths, ideal for architectural and structural applications. Machined aluminum provides precise tolerances and intricate detailing but is limited by raw material shapes and higher production costs for large volumes. Understanding the balance between extrusion's efficient shaping and machining's precision is crucial for optimizing metal fabrication projects.

Applications Suited for Each Method

Extruded aluminum is ideal for creating long, uniform profiles used in construction frameworks, automotive parts, and heat sinks due to its cost-efficiency and ability to produce complex cross-sectional shapes. Machined aluminum offers high precision and fine detail, making it suitable for aerospace components, custom fittings, and prototypes requiring tight tolerances and intricate designs. Each method serves distinct industrial needs, with extrusion favoring mass production and machining enabling specialized, low-volume manufacturing.

Surface Finish and Post-Processing Options

Extruded aluminum offers a uniform surface finish with visible striations from the extrusion die, providing a consistent texture ideal for anodizing and powder coating. Machined aluminum allows for a smoother, more precise surface finish with fine tolerances, suitable for polishing, bead blasting, and intricate detailing. Post-processing on extruded aluminum is often limited to coatings that enhance corrosion resistance, while machined aluminum supports a wider range of finishing techniques for aesthetic and functional customization.

Environmental Impact and Sustainability

Extruded aluminum offers a lower environmental impact compared to machined aluminum due to its energy-efficient manufacturing process that minimizes material waste and reduces carbon emissions. Machined aluminum involves more intensive use of materials and energy, generating higher scrap rates and increasing its ecological footprint. Selecting extruded aluminum enhances sustainability by promoting resource efficiency and reducing greenhouse gas emissions in metal production.

Extruded Aluminum vs Machined Aluminum Infographic

materialdif.com

materialdif.com