Pickling and passivation are crucial metal treatment processes aimed at enhancing corrosion resistance. Pickling involves the removal of surface impurities, oxides, and scale using acid solutions to prepare the metal for further treatment. Passivation creates a protective oxide layer on stainless steel, improving its durability and resistance to rust without altering the metal's surface texture.

Table of Comparison

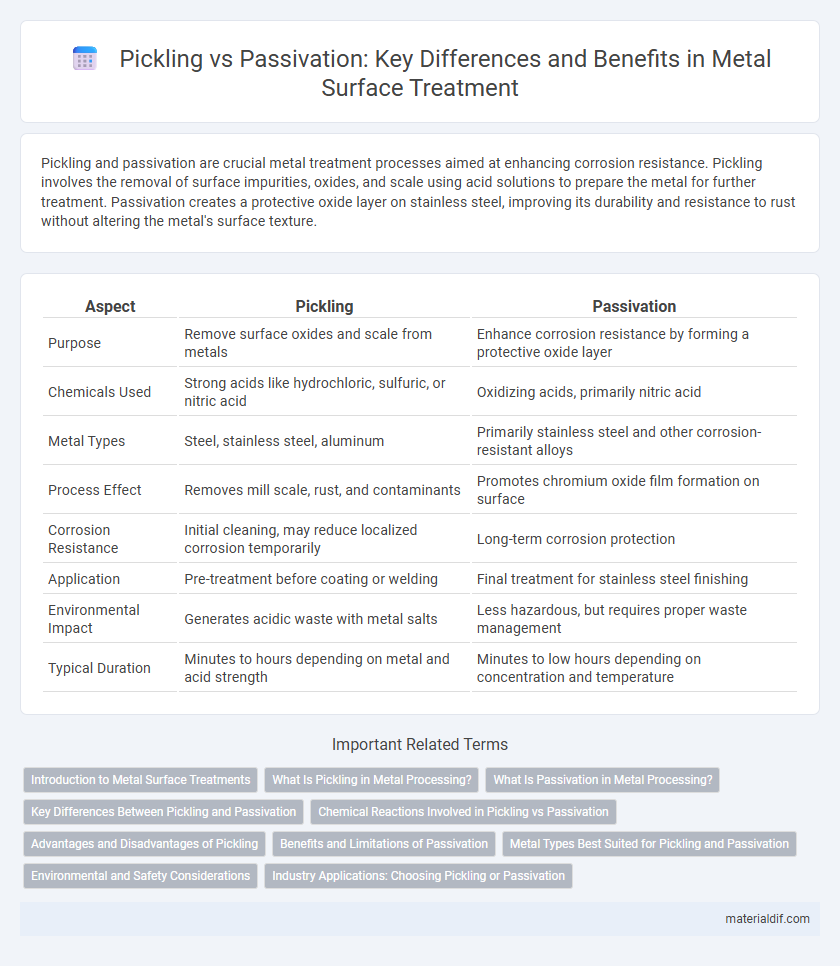

| Aspect | Pickling | Passivation |

|---|---|---|

| Purpose | Remove surface oxides and scale from metals | Enhance corrosion resistance by forming a protective oxide layer |

| Chemicals Used | Strong acids like hydrochloric, sulfuric, or nitric acid | Oxidizing acids, primarily nitric acid |

| Metal Types | Steel, stainless steel, aluminum | Primarily stainless steel and other corrosion-resistant alloys |

| Process Effect | Removes mill scale, rust, and contaminants | Promotes chromium oxide film formation on surface |

| Corrosion Resistance | Initial cleaning, may reduce localized corrosion temporarily | Long-term corrosion protection |

| Application | Pre-treatment before coating or welding | Final treatment for stainless steel finishing |

| Environmental Impact | Generates acidic waste with metal salts | Less hazardous, but requires proper waste management |

| Typical Duration | Minutes to hours depending on metal and acid strength | Minutes to low hours depending on concentration and temperature |

Introduction to Metal Surface Treatments

Pickling involves using acidic solutions to remove oxides, scale, and impurities from metal surfaces, enhancing cleanliness and preparing them for subsequent coatings or treatments. Passivation creates a protective oxide layer on stainless steel by chemically removing free iron and other contaminants, improving corrosion resistance without altering the metal's appearance. Both pickling and passivation are essential metal surface treatments that ensure durability, performance, and longevity in industrial and manufacturing applications.

What Is Pickling in Metal Processing?

Pickling in metal processing involves treating metal surfaces with acidic solutions to remove impurities such as rust, scale, and oxides, enhancing the metal's cleanliness and surface quality. Commonly used acids include hydrochloric acid, sulfuric acid, and nitric acid, which dissolve unwanted residues without damaging the base metal. This process is critical for preparing metals like stainless steel and carbon steel for subsequent treatments like passivation or coating, ensuring improved corrosion resistance and surface adhesion.

What Is Passivation in Metal Processing?

Passivation in metal processing refers to creating a thin, protective oxide layer on the surface of stainless steel or other metals to enhance corrosion resistance. This process typically involves treating the metal with an acid solution, such as nitric acid or citric acid, which removes free iron and contaminants without affecting the base metal. Passivation improves the longevity and durability of metal components by preventing rust and surface degradation.

Key Differences Between Pickling and Passivation

Pickling involves the use of acidic solutions to remove surface contaminants such as rust, scale, and oxides from metal, primarily stainless steel and carbon steel, while passivation enhances corrosion resistance by creating a protective oxide layer on the metal surface. Pickling often employs acids like hydrochloric or sulfuric acid for deep cleaning, whereas passivation typically uses nitric or citric acid to promote the formation of a passive film. The key difference lies in pickling's abrasive cleaning function compared to passivation's protective surface enhancement aimed at extending metal lifespan in corrosive environments.

Chemical Reactions Involved in Pickling vs Passivation

Pickling involves the aggressive chemical reaction of acids like hydrochloric or sulfuric acid with metal surfaces, effectively dissolving oxides and scale to clean and prepare the metal. Passivation relies on a controlled chemical reaction with oxidizing agents such as nitric acid, forming a thin, protective oxide layer that inhibits further corrosion. The key difference lies in pickling removing surface impurities through acid-metal reactions, while passivation chemically enhances the natural oxide film for corrosion resistance.

Advantages and Disadvantages of Pickling

Pickling is a metal surface treatment used to remove oxides, scale, and impurities through acid-based solutions, enhancing cleanliness and preparing surfaces for further processing like coating or welding. The primary advantages of pickling include effective scale removal, improved metal surface quality, and enhanced corrosion resistance after subsequent treatments. However, disadvantages involve the use of hazardous chemicals, potential environmental impact from acid waste, and the risk of metal surface damage or hydrogen embrittlement if not properly controlled.

Benefits and Limitations of Passivation

Passivation enhances corrosion resistance by forming a thin, inert oxide layer on stainless steel surfaces, improving durability and reducing maintenance costs. It preserves the metal's aesthetic appearance and prevents contamination by minimizing surface reactivity. However, passivation does not remove heavy scale or embedded impurities, limiting its effectiveness on unclean or heavily corroded substrates.

Metal Types Best Suited for Pickling and Passivation

Stainless steel and high-alloy metals are best suited for passivation, as the process enhances their corrosion resistance by forming a protective oxide layer. Pickling is more effective for carbon steel, stainless steel, and low-alloy metals, utilizing acid solutions like hydrochloric or nitric acid to remove scale, rust, and oxides. Choosing the appropriate method depends on the metal composition and desired surface finish to optimize durability and corrosion protection.

Environmental and Safety Considerations

Pickling involves using strong acids like hydrochloric or sulfuric acid to remove scale and impurities from metal surfaces, posing significant environmental risks due to hazardous acid waste and requiring stringent safety measures for handling corrosive chemicals. Passivation uses milder chemicals, such as nitric acid or citric acid, to enhance the corrosion resistance of stainless steel by forming a protective oxide layer, resulting in less hazardous waste and safer operational conditions. Employing proper waste treatment and protective equipment is essential in both processes to minimize ecological impact and ensure worker safety in metal finishing applications.

Industry Applications: Choosing Pickling or Passivation

Pickling is widely applied in heavy industries such as steel manufacturing and construction for removing scale, rust, and weld oxides to restore metal surfaces before further processing. Passivation is preferred in the pharmaceutical, aerospace, and food processing industries where corrosion resistance and contamination prevention are critical, enhancing stainless steel durability by forming a protective oxide layer. The choice between pickling and passivation depends on the degree of surface contamination and the specific corrosion resistance requirements of the industrial application.

Pickling vs Passivation Infographic

materialdif.com

materialdif.com