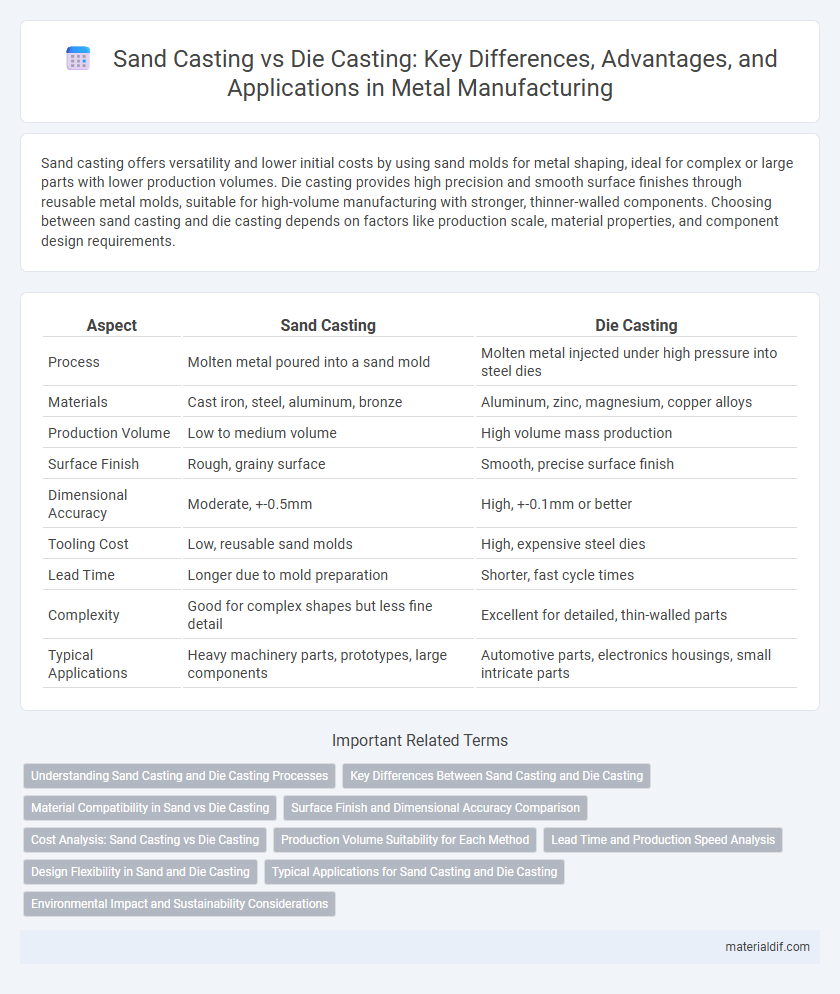

Sand casting offers versatility and lower initial costs by using sand molds for metal shaping, ideal for complex or large parts with lower production volumes. Die casting provides high precision and smooth surface finishes through reusable metal molds, suitable for high-volume manufacturing with stronger, thinner-walled components. Choosing between sand casting and die casting depends on factors like production scale, material properties, and component design requirements.

Table of Comparison

| Aspect | Sand Casting | Die Casting |

|---|---|---|

| Process | Molten metal poured into a sand mold | Molten metal injected under high pressure into steel dies |

| Materials | Cast iron, steel, aluminum, bronze | Aluminum, zinc, magnesium, copper alloys |

| Production Volume | Low to medium volume | High volume mass production |

| Surface Finish | Rough, grainy surface | Smooth, precise surface finish |

| Dimensional Accuracy | Moderate, +-0.5mm | High, +-0.1mm or better |

| Tooling Cost | Low, reusable sand molds | High, expensive steel dies |

| Lead Time | Longer due to mold preparation | Shorter, fast cycle times |

| Complexity | Good for complex shapes but less fine detail | Excellent for detailed, thin-walled parts |

| Typical Applications | Heavy machinery parts, prototypes, large components | Automotive parts, electronics housings, small intricate parts |

Understanding Sand Casting and Die Casting Processes

Sand casting involves creating a mold from a sand mixture that shapes molten metal into complex forms with excellent dimensional accuracy and surface texture. Die casting uses high-pressure injection of molten metal into steel molds, producing parts with superior strength, fine detail, and smooth finishes ideal for high-volume manufacturing. Both processes cater to different production needs, with sand casting favoring large, low-volume components and die casting excelling in rapid, consistent, and precise metal part fabrication.

Key Differences Between Sand Casting and Die Casting

Sand casting involves creating a mold from compacted sand, allowing for complex shapes and large parts but with lower dimensional accuracy and surface finish. Die casting uses reusable metal molds under high pressure, producing high-precision components with smooth surfaces and faster production rates suitable for high-volume manufacturing. Cost differences are significant: sand casting has lower initial setup costs ideal for small runs, while die casting requires expensive tooling but lowers per-unit cost for mass production.

Material Compatibility in Sand vs Die Casting

Sand casting accommodates a broader range of metals, including ferrous alloys like cast iron and steel, due to its ability to withstand extremely high temperatures. Die casting is primarily suited for non-ferrous metals such as aluminum, zinc, and magnesium, as the process involves injecting molten metal into steel molds that may degrade under intense heat. Understanding material compatibility ensures optimal casting quality and durability for specific metal applications.

Surface Finish and Dimensional Accuracy Comparison

Sand casting produces rougher surface finishes due to its granular mold material, typically resulting in a surface roughness of 1.6 to 3.2 micrometers. Die casting offers superior surface finish with smoother textures ranging from 0.4 to 1.6 micrometers, achieved through high-pressure injection into metal molds. Dimensional accuracy in die casting is higher, often within +-0.1 mm, compared to sand casting's tolerance range of +-0.5 mm, making die casting preferable for precision components.

Cost Analysis: Sand Casting vs Die Casting

Sand casting offers lower initial tooling costs, making it cost-effective for small production runs and prototypes, while die casting involves significant upfront investment in durable molds, suited for high-volume manufacturing. The per-unit cost in sand casting remains relatively high due to longer cycle times and manual labor, contrasting with the faster production rates and lower variable costs of die casting. Overall, sand casting is preferable for low quantities and complex shapes, whereas die casting is economically advantageous for mass production with consistent part quality.

Production Volume Suitability for Each Method

Sand casting is ideal for low to medium production volumes due to its flexibility and lower tooling costs, making it suitable for custom or limited-run metal parts. Die casting excels in high production volumes because of its high precision and rapid cycle times, which lower per-unit costs significantly as output increases. Manufacturing decisions often hinge on balancing initial tooling investments against desired production scale and part complexity.

Lead Time and Production Speed Analysis

Sand casting requires longer lead time due to the need for mold preparation and cooling, making it suitable for low to medium production volumes. Die casting offers significantly faster production speed with reusable metal molds, enabling high-volume manufacturing and quicker turnaround. The choice between sand casting and die casting hinges on balancing lead time efficiency with production scale and complexity.

Design Flexibility in Sand and Die Casting

Sand casting offers superior design flexibility due to its ability to create complex geometries and large components with varying thicknesses, making it ideal for custom or low-volume production. Die casting provides less design freedom because of the rigidity of metal molds but excels in producing high-precision, intricate designs rapidly for high-volume manufacturing. The choice between sand and die casting depends on whether design complexity or production efficiency is the primary requirement.

Typical Applications for Sand Casting and Die Casting

Sand casting is commonly used for producing large metal components such as engine blocks, pump housings, and industrial machinery parts due to its cost-effectiveness and versatility with various metal alloys. Die casting is typically applied in manufacturing high-volume, precision parts like automotive components, electrical housings, and consumer electronics made from non-ferrous metals like aluminum, zinc, and magnesium. The choice between sand casting and die casting hinges on production volume, part complexity, and material properties.

Environmental Impact and Sustainability Considerations

Sand casting produces more waste due to the single-use sand molds, while die casting utilizes reusable metal molds, reducing material wastage. Sand casting consumes less energy compared to the high energy demand of molten metal injection in die casting, impacting carbon emissions differently. Recycling of die casting alloys is more efficient, supporting sustainability goals more effectively than the often discarded sand foundry residues.

Sand Casting vs Die Casting Infographic

materialdif.com

materialdif.com