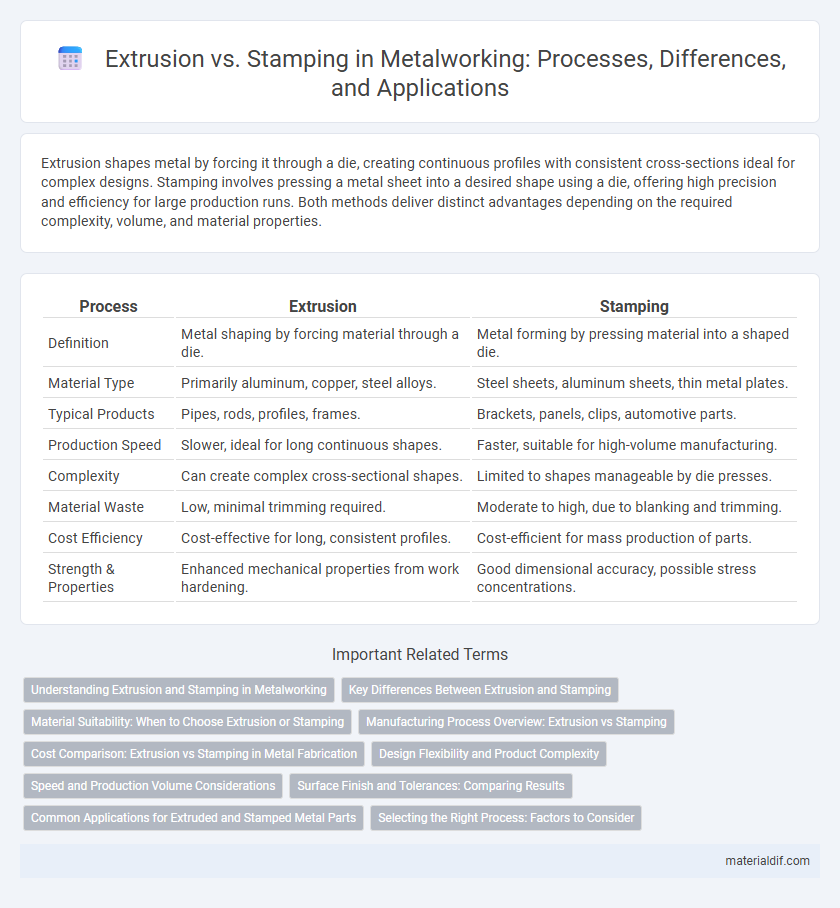

Extrusion shapes metal by forcing it through a die, creating continuous profiles with consistent cross-sections ideal for complex designs. Stamping involves pressing a metal sheet into a desired shape using a die, offering high precision and efficiency for large production runs. Both methods deliver distinct advantages depending on the required complexity, volume, and material properties.

Table of Comparison

| Process | Extrusion | Stamping |

|---|---|---|

| Definition | Metal shaping by forcing material through a die. | Metal forming by pressing material into a shaped die. |

| Material Type | Primarily aluminum, copper, steel alloys. | Steel sheets, aluminum sheets, thin metal plates. |

| Typical Products | Pipes, rods, profiles, frames. | Brackets, panels, clips, automotive parts. |

| Production Speed | Slower, ideal for long continuous shapes. | Faster, suitable for high-volume manufacturing. |

| Complexity | Can create complex cross-sectional shapes. | Limited to shapes manageable by die presses. |

| Material Waste | Low, minimal trimming required. | Moderate to high, due to blanking and trimming. |

| Cost Efficiency | Cost-effective for long, consistent profiles. | Cost-efficient for mass production of parts. |

| Strength & Properties | Enhanced mechanical properties from work hardening. | Good dimensional accuracy, possible stress concentrations. |

Understanding Extrusion and Stamping in Metalworking

Extrusion in metalworking involves forcing heated metal through a shaped die to create continuous profiles with uniform cross-sections, ideal for complex shapes and long lengths. Stamping uses a press to shape or cut metal sheets by applying high pressure, suitable for producing precise and detailed parts rapidly in large volumes. Understanding these processes helps optimize production efficiency and material utilization in metal fabrication.

Key Differences Between Extrusion and Stamping

Extrusion involves forcing heated metal through a die to create long objects with a consistent cross-section, offering excellent strength and design versatility for complex shapes. Stamping uses a press to shape or cut metal sheets by applying high pressure, ideal for producing flat parts quickly with high precision. The key difference lies in extrusion's ability to form continuous profiles versus stamping's efficiency in high-volume, detailed sheet metal components.

Material Suitability: When to Choose Extrusion or Stamping

Extrusion is ideal for metals like aluminum and copper that require continuous, uniform shapes with excellent structural strength and flexibility. Stamping suits high-volume production of thin sheet metals such as steel and stainless steel, offering precise and complex designs with minimal material waste. Choosing between extrusion and stamping depends on metal thickness, desired shape complexity, and production volume, with extrusion excelling in long profiles and stamping optimal for detailed, high-speed sheet metal parts.

Manufacturing Process Overview: Extrusion vs Stamping

Extrusion involves forcing heated metal through a die to create continuous shapes with uniform cross-sections, ideal for producing complex profiles and long lengths with consistent mechanical properties. Stamping utilizes high-pressure dies and presses to cut, shape, or form metal sheets into specific parts, offering high precision and efficiency for large-scale production of components with intricate details. Manufacturing process selection depends on factors like material type, product geometry, production volume, and dimensional tolerances, with extrusion excelling in structural applications and stamping preferred for high-speed mass production of sheet metal parts.

Cost Comparison: Extrusion vs Stamping in Metal Fabrication

Extrusion typically involves higher initial tooling costs but offers lower per-unit costs for high-volume metal fabrication due to continuous production capabilities. Stamping has lower upfront expenses and faster cycle times, making it cost-effective for mid to large production runs but can become expensive with complex dies or lower volumes. Evaluating volume requirements and part complexity is crucial for optimizing cost efficiency between extrusion and stamping processes.

Design Flexibility and Product Complexity

Extrusion offers superior design flexibility by enabling complex cross-sectional profiles and continuous shapes impossible to achieve with stamping, which is limited to flat sheets. Stamping excels in high-volume production of simpler, two-dimensional parts but struggles with intricate geometries and variable thicknesses. Metal extrusion supports intricate product complexity including hollow sections and multiple cavities, while stamping is constrained by die limitations and material stretchability.

Speed and Production Volume Considerations

Extrusion processes enable high-speed metal forming with continuous production, ideal for large-volume runs of consistent cross-sectional profiles, while stamping offers rapid processing suitable for complex shapes but is better suited for high-volume batch production due to die setup times. Extrusion typically achieves faster cycle times per unit in long production runs, whereas stamping excels in speed during mass production of flat or sheet metal components. Production volume considerations favor extrusion for uniform profiles at scale, and stamping for versatile part geometries in extensive quantities.

Surface Finish and Tolerances: Comparing Results

Extrusion processes often produce smoother surface finishes with consistent texture due to the continuous flow of metal through a die, resulting in tighter dimensional tolerances typically within +-0.1 mm. Stamping can generate varied surface finishes depending on die quality and material type, with tolerances generally wider, around +-0.2 mm, caused by metal deformation and spring-back effects. Surface finish quality in extrusion favors applications requiring precision and aesthetics, whereas stamping suits high-volume parts with acceptable variation and secondary finishing.

Common Applications for Extruded and Stamped Metal Parts

Extruded metal parts are commonly used in construction frameworks, automotive components, and heat sinks due to their ability to create complex cross-sections that enhance structural integrity and thermal management. Stamped metal parts find frequent applications in electronic housings, appliance panels, and automotive body panels, benefiting from high-speed production and precise dimensional control. Both methods serve key roles in manufacturing, with extrusion favoring continuous profiles and stamping excelling in producing detailed, high-volume flat parts.

Selecting the Right Process: Factors to Consider

Selecting the right metal forming process involves evaluating material type, part complexity, production volume, and cost constraints. Extrusion excels in creating continuous profiles with uniform cross-sections, ideal for aluminum and softer metals, while stamping suits high-speed production of intricate, thin sheet metal parts. Consider tolerances, tooling costs, and post-processing requirements to determine whether extrusion or stamping aligns best with your manufacturing needs.

Extrusion vs Stamping Infographic

materialdif.com

materialdif.com