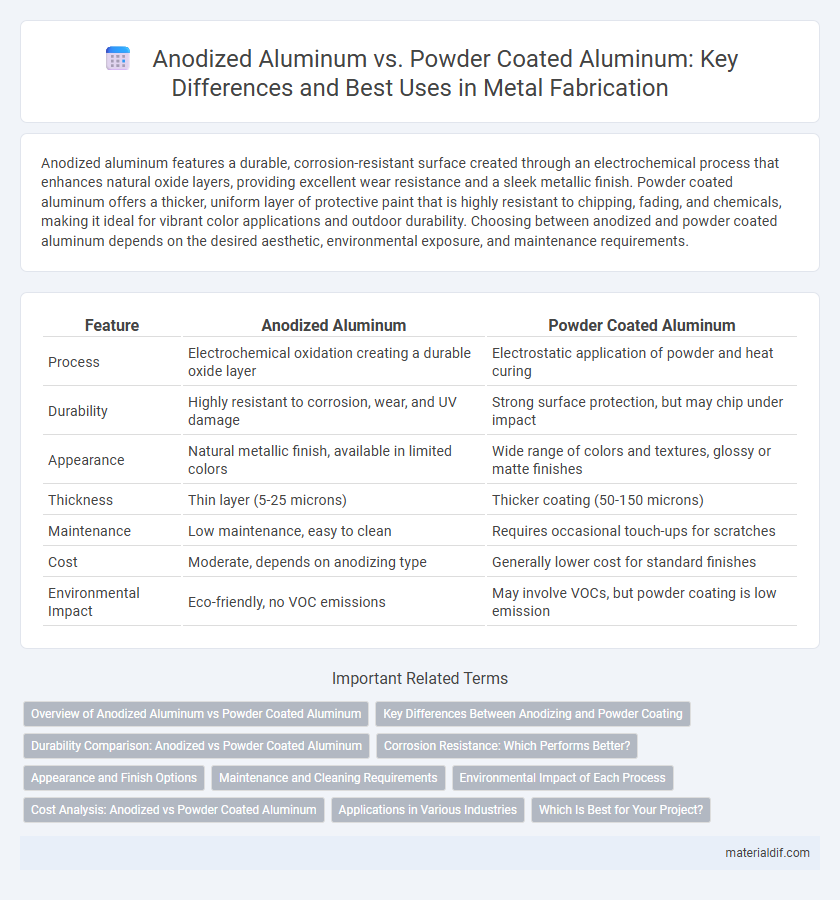

Anodized aluminum features a durable, corrosion-resistant surface created through an electrochemical process that enhances natural oxide layers, providing excellent wear resistance and a sleek metallic finish. Powder coated aluminum offers a thicker, uniform layer of protective paint that is highly resistant to chipping, fading, and chemicals, making it ideal for vibrant color applications and outdoor durability. Choosing between anodized and powder coated aluminum depends on the desired aesthetic, environmental exposure, and maintenance requirements.

Table of Comparison

| Feature | Anodized Aluminum | Powder Coated Aluminum |

|---|---|---|

| Process | Electrochemical oxidation creating a durable oxide layer | Electrostatic application of powder and heat curing |

| Durability | Highly resistant to corrosion, wear, and UV damage | Strong surface protection, but may chip under impact |

| Appearance | Natural metallic finish, available in limited colors | Wide range of colors and textures, glossy or matte finishes |

| Thickness | Thin layer (5-25 microns) | Thicker coating (50-150 microns) |

| Maintenance | Low maintenance, easy to clean | Requires occasional touch-ups for scratches |

| Cost | Moderate, depends on anodizing type | Generally lower cost for standard finishes |

| Environmental Impact | Eco-friendly, no VOC emissions | May involve VOCs, but powder coating is low emission |

Overview of Anodized Aluminum vs Powder Coated Aluminum

Anodized aluminum features a durable oxide layer created through an electrochemical process, enhancing corrosion resistance and surface hardness while maintaining the metal's natural metallic appearance. Powder coated aluminum involves applying a dry powder resin cured under heat, producing a thick, protective, and colorful finish with superior impact resistance and UV protection. Both methods improve aluminum's durability, but anodizing excels in wear resistance and conductivity, whereas powder coating offers greater color versatility and surface protection.

Key Differences Between Anodizing and Powder Coating

Anodized aluminum features a durable, corrosion-resistant oxide layer formed through an electrochemical process, enhancing metal hardness and wear resistance while maintaining the original metallic appearance. Powder coated aluminum involves applying a dry powder that is cured under heat to create a thick, protective, and colorful finish, offering superior impact resistance and a broader range of color options. Key differences include anodizing's emphasis on surface hardness and natural metallic luster versus powder coating's focus on vibrant color variety and thicker, more flexible protective layers.

Durability Comparison: Anodized vs Powder Coated Aluminum

Anodized aluminum offers enhanced corrosion resistance through a thick oxide layer that integrates with the metal surface, providing superior durability against environmental wear and UV exposure. Powder coated aluminum features a resilient polymer finish that shields against chipping, scratching, and fading, making it highly durable in physical impact scenarios. Durability in anodized aluminum excels in chemical and oxidation resistance, while powder coating outperforms in mechanical protection and color longevity under abrasion.

Corrosion Resistance: Which Performs Better?

Anodized aluminum features a thick, durable oxide layer that provides superior corrosion resistance by protecting the base metal from environmental exposure. Powder coated aluminum relies on a polymer resin layer that offers good corrosion resistance but can chip or scratch, exposing the metal underneath to potential corrosion. In highly corrosive environments, anodized aluminum generally performs better over time due to its integral oxide barrier compared to the mechanical durability limits of powder coatings.

Appearance and Finish Options

Anodized aluminum offers a smooth, metallic finish with a natural, translucent color that enhances corrosion resistance while maintaining the metal's texture. Powder coated aluminum provides a thicker, opaque layer available in a wide array of vibrant colors and finishes, delivering superior durability against chipping and fading. Both finishes improve metal protection, but anodizing retains a sleek, metallic look, whereas powder coating allows for more customizable and vibrant aesthetic options.

Maintenance and Cleaning Requirements

Anodized aluminum requires minimal maintenance due to its corrosion-resistant oxide layer that prevents rust and fading, making it easy to clean with mild soap and water. Powder-coated aluminum has a durable finish that resists chipping and scratching but may need more frequent cleaning to remove dirt and prevent buildup, especially in outdoor environments. Both finishes benefit from regular dusting and gentle washing to preserve their appearance and extend their lifespan.

Environmental Impact of Each Process

Anodized aluminum undergoes an electrochemical process that enhances corrosion resistance without adding hazardous chemicals, resulting in minimal environmental pollution and fully recyclable surface layers. Powder coating involves applying a dry powder cured under heat, which emits negligible volatile organic compounds (VOCs) but may produce hazardous waste if not properly managed. The anodizing process typically consumes less energy and produces less waste compared to powder coating, making it a more sustainable choice in metal finishing.

Cost Analysis: Anodized vs Powder Coated Aluminum

Anodized aluminum generally incurs higher initial costs due to complex electrolytic processes but offers superior durability and corrosion resistance, reducing long-term maintenance expenses. Powder coated aluminum presents a cost-effective option with lower upfront investment and faster application, though it may require more frequent recoating over time. Evaluating total lifecycle costs highlights anodized aluminum's advantage in applications demanding enhanced longevity despite its premium price point.

Applications in Various Industries

Anodized aluminum offers enhanced corrosion resistance and durability, making it ideal for aerospace, automotive, and electronics where lightweight strength and surface protection are critical. Powder coated aluminum provides a robust, decorative finish suited for architectural panels, outdoor furniture, and industrial equipment requiring color versatility and impact resistance. Both finishes are employed across industries but anodizing is preferred for precision and longevity, while powder coating excels in aesthetic customization and thicker surface protection.

Which Is Best for Your Project?

Anodized aluminum offers superior corrosion resistance and a more durable, scratch-resistant surface, ideal for architectural and marine applications where longevity is critical. Powder coated aluminum provides a wider range of color options and a thicker protective layer, making it perfect for outdoor furniture and automotive parts exposed to harsh weather. Choosing between anodized and powder coated aluminum depends on the specific environmental exposure, desired aesthetics, and maintenance expectations of your project.

Anodized Aluminum vs Powder Coated Aluminum Infographic

materialdif.com

materialdif.com