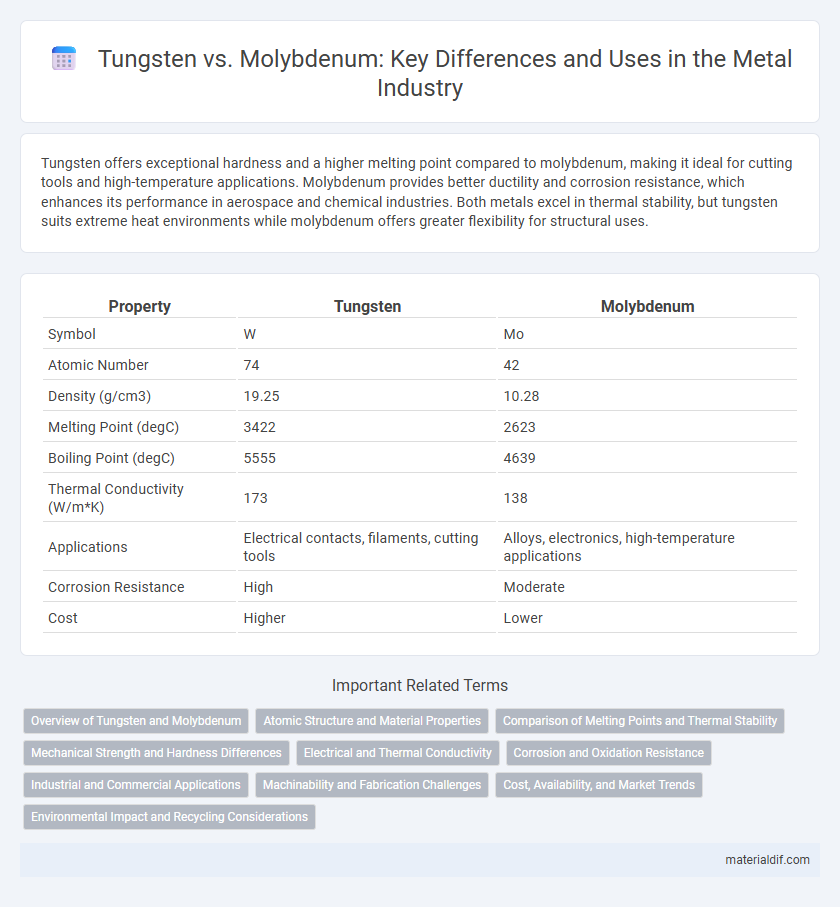

Tungsten offers exceptional hardness and a higher melting point compared to molybdenum, making it ideal for cutting tools and high-temperature applications. Molybdenum provides better ductility and corrosion resistance, which enhances its performance in aerospace and chemical industries. Both metals excel in thermal stability, but tungsten suits extreme heat environments while molybdenum offers greater flexibility for structural uses.

Table of Comparison

| Property | Tungsten | Molybdenum |

|---|---|---|

| Symbol | W | Mo |

| Atomic Number | 74 | 42 |

| Density (g/cm3) | 19.25 | 10.28 |

| Melting Point (degC) | 3422 | 2623 |

| Boiling Point (degC) | 5555 | 4639 |

| Thermal Conductivity (W/m*K) | 173 | 138 |

| Applications | Electrical contacts, filaments, cutting tools | Alloys, electronics, high-temperature applications |

| Corrosion Resistance | High | Moderate |

| Cost | Higher | Lower |

Overview of Tungsten and Molybdenum

Tungsten and molybdenum are refractory metals known for their high melting points and exceptional resistance to wear and corrosion. Tungsten features the highest melting point of all metals at 3422degC, making it ideal for applications in cutting tools and high-temperature environments, while molybdenum, with a melting point of 2623degC, excels in alloying agents to enhance strength and conductivity. Both metals are widely used in aerospace, electronics, and industrial manufacturing, with tungsten providing superior density and hardness, and molybdenum offering better ductility and thermal expansion properties.

Atomic Structure and Material Properties

Tungsten features an atomic number of 74 and a body-centered cubic crystal structure, resulting in exceptional hardness and a melting point of 3422degC, the highest among metals. Molybdenum, with atomic number 42, also exhibits a body-centered cubic structure but has a lower melting point of 2623degC and slightly less hardness, making it more ductile. Tungsten's denser atomic arrangement contributes to superior wear resistance, whereas molybdenum provides better thermal conductivity and corrosion resistance in high-temperature environments.

Comparison of Melting Points and Thermal Stability

Tungsten has an exceptionally high melting point of 3422degC, significantly surpassing molybdenum's melting point of 2623degC, which makes tungsten more suitable for applications requiring extreme heat resistance. Both metals exhibit excellent thermal stability, but tungsten maintains its structural integrity at higher temperatures, contributing to its widespread use in high-temperature environments such as aerospace and industrial heating elements. Molybdenum offers better thermal conductivity and lower density, which can be advantageous in applications where weight and heat dissipation are critical factors.

Mechanical Strength and Hardness Differences

Tungsten exhibits higher mechanical strength and hardness compared to molybdenum, with a tensile strength of approximately 1510 MPa versus molybdenum's 550 MPa. Tungsten's Vickers hardness typically ranges between 3430 and 4160 MPa, outperforming molybdenum's hardness of around 1600 MPa. These differences make tungsten ideal for extreme wear-resistant applications, while molybdenum suits scenarios requiring moderate strength with better ductility.

Electrical and Thermal Conductivity

Tungsten exhibits electrical conductivity around 18.2 million Siemens per meter (MS/m) and thermal conductivity of approximately 173 W/m*K, making it a superior choice for applications requiring high heat resistance and efficient electrical flow. Molybdenum shows electrical conductivity near 19.3 MS/m and thermal conductivity of about 138 W/m*K, offering better conductivity but lower thermal dissipation compared to tungsten. These properties influence their selection in electronics, with tungsten favored in high-temperature environments and molybdenum preferred where higher electrical conductivity is critical.

Corrosion and Oxidation Resistance

Tungsten exhibits exceptional corrosion resistance and maintains stability at temperatures above 1,000degC due to its dense atomic structure, making it ideal for harsh environments. Molybdenum offers strong oxidation resistance up to around 600degC, but it oxidizes rapidly at higher temperatures, limiting its use in extreme conditions. Both metals form protective oxide layers; however, tungsten's oxide layer is more stable and less prone to degradation, enhancing its performance in high-corrosion settings.

Industrial and Commercial Applications

Tungsten exhibits exceptional hardness and a melting point exceeding 3400degC, making it ideal for industrial applications such as cutting tools, electrical contacts, and filaments in lighting. Molybdenum, with a melting point of approximately 2623degC and superior corrosion resistance, is widely used in steel alloys, aircraft parts, and chemical processing equipment. Both metals contribute significantly to high-temperature environments, but tungsten's density and thermal conductivity offer advantages in wear resistance, while molybdenum's flexibility and strength enhance alloy performance.

Machinability and Fabrication Challenges

Tungsten exhibits lower machinability compared to molybdenum due to its high hardness and brittleness, leading to increased tool wear and slower cutting speeds. Molybdenum offers better fabrication performance with improved ductility and thermal conductivity, enabling easier forming and welding processes. Both metals require precise control of machining parameters to minimize microcracking and optimize surface finish during fabrication.

Cost, Availability, and Market Trends

Tungsten typically commands a higher price due to its denser supply constraints and more complex extraction processes compared to molybdenum. Molybdenum enjoys broader availability, especially as a byproduct of copper mining, which stabilizes its market and cost structure. Current market trends indicate rising demand for tungsten in aerospace and defense sectors, while molybdenum's growth is driven primarily by the steel industry's need for corrosion-resistant alloys.

Environmental Impact and Recycling Considerations

Tungsten and molybdenum exhibit distinct environmental impacts, with tungsten mining often causing significant habitat disruption due to its extraction from hard rock deposits, while molybdenum mining tends to have a lower footprint because it is frequently obtained as a byproduct of copper mining. Tungsten's recycling rate remains relatively low at approximately 1-2%, attributed to its high melting point and complex extraction processes, whereas molybdenum benefits from more established recycling systems, recovering around 50% of available scrap metal for reuse. Both metals require careful lifecycle management to minimize ecological harm, but molybdenum's integration into copper industries enhances its overall sustainability compared to tungsten.

Tungsten vs Molybdenum Infographic

materialdif.com

materialdif.com