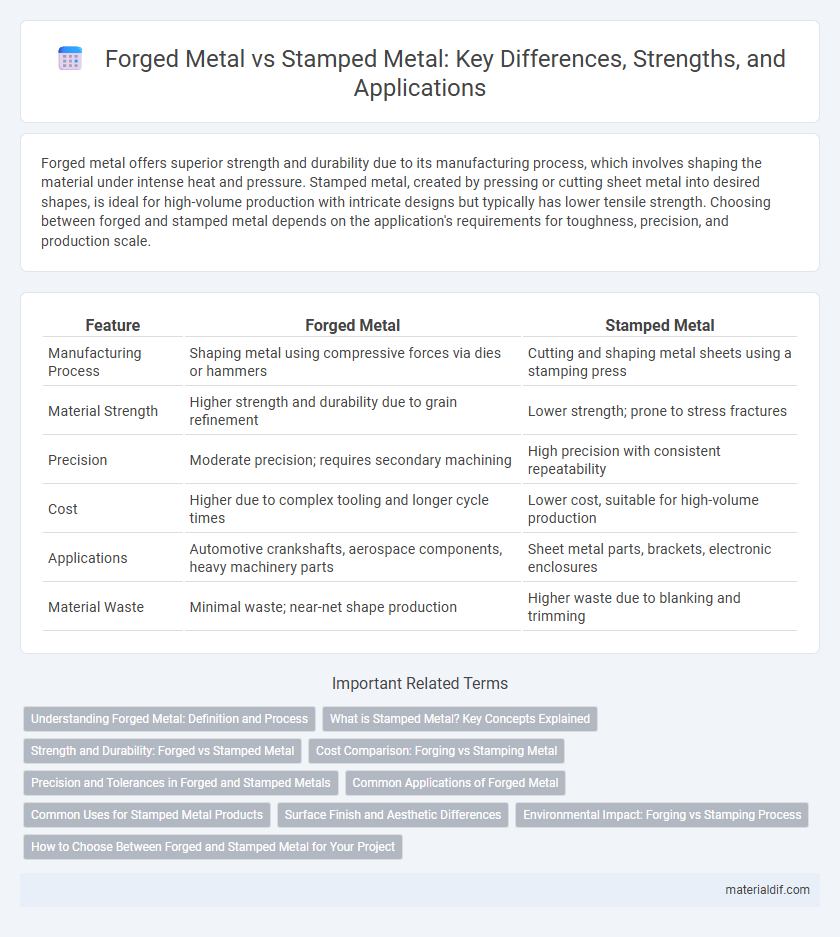

Forged metal offers superior strength and durability due to its manufacturing process, which involves shaping the material under intense heat and pressure. Stamped metal, created by pressing or cutting sheet metal into desired shapes, is ideal for high-volume production with intricate designs but typically has lower tensile strength. Choosing between forged and stamped metal depends on the application's requirements for toughness, precision, and production scale.

Table of Comparison

| Feature | Forged Metal | Stamped Metal |

|---|---|---|

| Manufacturing Process | Shaping metal using compressive forces via dies or hammers | Cutting and shaping metal sheets using a stamping press |

| Material Strength | Higher strength and durability due to grain refinement | Lower strength; prone to stress fractures |

| Precision | Moderate precision; requires secondary machining | High precision with consistent repeatability |

| Cost | Higher due to complex tooling and longer cycle times | Lower cost, suitable for high-volume production |

| Applications | Automotive crankshafts, aerospace components, heavy machinery parts | Sheet metal parts, brackets, electronic enclosures |

| Material Waste | Minimal waste; near-net shape production | Higher waste due to blanking and trimming |

Understanding Forged Metal: Definition and Process

Forged metal is produced by heating a metal workpiece and shaping it using compressive forces, often with a hammer or press, to refine its grain structure and enhance strength. This process improves mechanical properties such as toughness, fatigue resistance, and durability, making forged components ideal for high-stress applications. Unlike stamped metal, which is cut and shaped from sheet metal, forging produces parts with superior structural integrity and uniformity.

What is Stamped Metal? Key Concepts Explained

Stamped metal is a manufacturing process where flat metal sheets are pressed into specific shapes using high-pressure stamping dies. This method enables rapid production of complex, precise components with consistent dimensions and smooth surface finishes. Common applications include automotive parts, appliances, and electronic enclosures due to its cost-effectiveness and scalability compared to forged metal.

Strength and Durability: Forged vs Stamped Metal

Forged metal exhibits superior strength and durability due to its manufacturing process, where metal is heated and shaped under high pressure, resulting in a dense, grain-aligned structure. Stamped metal, created by pressing sheets of metal into shapes, often has uniform thickness but lacks the enhanced grain flow, making it less resistant to impact and fatigue. As a result, forged metal components are the preferred choice for high-stress applications requiring maximum toughness and longevity.

Cost Comparison: Forging vs Stamping Metal

Forged metal generally involves higher initial costs due to complex dies and longer production times, but it offers superior strength and durability, making it cost-effective for high-stress applications. Stamped metal boasts lower tooling and production expenses with faster cycle times, suitable for large-volume, less-demanding parts. Evaluating long-term performance against upfront expenses is essential when choosing between forging and stamping processes.

Precision and Tolerances in Forged and Stamped Metals

Forged metal offers superior precision and tighter tolerances compared to stamped metal due to its controlled deformation process, which aligns the metal grain structure and minimizes internal defects. Stamped metal, while efficient for high-volume production, typically exhibits looser tolerances and less consistent precision because it involves cutting or shaping metal sheets without altering the grain flow. The enhanced accuracy in forged metal makes it ideal for critical applications in aerospace and automotive industries where dimensional stability and mechanical strength are paramount.

Common Applications of Forged Metal

Forged metal is commonly used in critical applications requiring high strength and durability, such as automotive crankshafts, aircraft landing gear, and heavy machinery components. Its superior grain structure and density make it ideal for tools, fasteners, and structural parts exposed to high stress and impact conditions. These properties ensure forged metal components deliver enhanced fatigue resistance and reliability in demanding environments.

Common Uses for Stamped Metal Products

Stamped metal products are widely used in the automotive industry for components like body panels, brackets, and chassis parts due to their precision and cost-effectiveness. Consumer electronics also rely on stamped metal for enclosures, connectors, and heat sinks, benefiting from high-volume production capabilities. Additionally, household appliances incorporate stamped metal parts such as panels and frames, leveraging durability and uniformity in design.

Surface Finish and Aesthetic Differences

Forged metal typically exhibits a smoother and more refined surface finish due to the controlled deformation process, which enhances grain structure and reduces surface imperfections. Stamped metal often has a more uniform but less detailed surface appearance, with possible tool marks and slight roughness resulting from high-pressure stamping dies. The aesthetic difference is prominent, as forged metal offers a premium, handcrafted look, whereas stamped metal provides a consistent, mass-produced finish ideal for high-volume applications.

Environmental Impact: Forging vs Stamping Process

Forged metal typically has a lower environmental impact than stamped metal due to its efficient material usage and reduced waste generation during the forging process. Forging produces parts with superior strength and durability, which extends product life and decreases the frequency of replacements, further minimizing resource consumption. Stamping often consumes more energy and produces more scrap metal, leading to higher emissions and increased environmental footprint.

How to Choose Between Forged and Stamped Metal for Your Project

Choosing between forged and stamped metal depends on the project's strength and precision requirements. Forged metal offers superior durability and tensile strength, ideal for high-stress applications, while stamped metal provides cost-effective production with consistent shapes suited for large-volume, less demanding parts. Assess factors such as mechanical properties, design complexity, and production scale to determine the optimal metal fabrication method.

Forged Metal vs Stamped Metal Infographic

materialdif.com

materialdif.com