Laser cutting offers high precision and clean edges, making it ideal for detailed metalwork and thin materials. Plasma cutting excels in speed and cost-effectiveness, especially for thicker metals and large-scale projects. Both techniques require proper equipment and material considerations to optimize performance and quality.

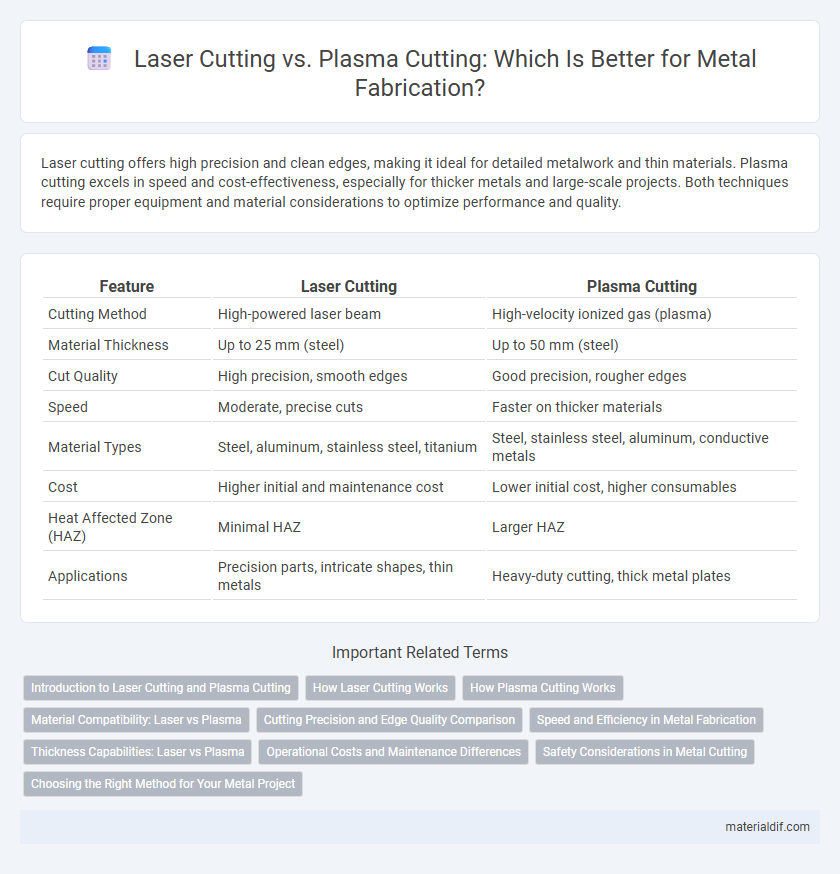

Table of Comparison

| Feature | Laser Cutting | Plasma Cutting |

|---|---|---|

| Cutting Method | High-powered laser beam | High-velocity ionized gas (plasma) |

| Material Thickness | Up to 25 mm (steel) | Up to 50 mm (steel) |

| Cut Quality | High precision, smooth edges | Good precision, rougher edges |

| Speed | Moderate, precise cuts | Faster on thicker materials |

| Material Types | Steel, aluminum, stainless steel, titanium | Steel, stainless steel, aluminum, conductive metals |

| Cost | Higher initial and maintenance cost | Lower initial cost, higher consumables |

| Heat Affected Zone (HAZ) | Minimal HAZ | Larger HAZ |

| Applications | Precision parts, intricate shapes, thin metals | Heavy-duty cutting, thick metal plates |

Introduction to Laser Cutting and Plasma Cutting

Laser cutting employs a concentrated beam of coherent light to precisely cut metals, offering high accuracy and smooth edges ideal for intricate designs. Plasma cutting utilizes an ionized gas jet at high temperatures to melt and blow away metal, providing efficient cutting for thicker and conductive materials. Both techniques vary in speed, precision, and operational costs, influencing their application in metal fabrication industries.

How Laser Cutting Works

Laser cutting uses a highly focused laser beam to melt, burn, or vaporize metal with extreme precision, enabling intricate designs and fine details. The process involves directing the laser through optics and computer numerical control (CNC) systems to achieve clean edges and tight tolerances. Typically, inert gases like nitrogen or oxygen assist in clearing molten material, improving cut quality and speed on various metal types such as stainless steel, aluminum, and carbon steel.

How Plasma Cutting Works

Plasma cutting works by sending an electric arc through a gas that passes through a constricted opening, turning the gas into plasma capable of melting metal. The high-velocity plasma stream blows molten metal away from the cut, creating precise and clean cuts in conductive metals like steel, aluminum, and copper. This method is especially effective for thicker materials where laser cutting may struggle to maintain speed or depth efficiency.

Material Compatibility: Laser vs Plasma

Laser cutting offers superior precision and is highly effective on thin metals such as stainless steel, aluminum, and mild steel, with minimal heat distortion. Plasma cutting excels at cutting thicker metals, including carbon steel and other conductive metals up to several inches thick, where laser cutting becomes less efficient and more expensive. Both methods depend on the material's thickness and type, but laser cutting is preferred for fine detail and thin materials, while plasma cutting is optimal for fast, cost-effective cuts on thicker, conductive metals.

Cutting Precision and Edge Quality Comparison

Laser cutting offers superior cutting precision with a narrow kerf width and minimal heat-affected zone, resulting in cleaner edges and tighter tolerances compared to plasma cutting. Plasma cutting typically produces a wider kerf and more dross, leading to rougher edges that often require secondary finishing. For applications demanding high-edge quality and fine detail, laser cutting is the preferred choice due to its focused beam and controlled cutting environment.

Speed and Efficiency in Metal Fabrication

Laser cutting offers higher precision and faster processing speeds for thin to medium-thickness metals, enhancing overall efficiency in metal fabrication. Plasma cutting excels in speed when working with thicker metal sheets, providing rapid material removal but with slightly lower precision. Choosing between laser and plasma cutting depends on the specific thickness and tolerance requirements of the metal fabrication project.

Thickness Capabilities: Laser vs Plasma

Laser cutting excels in precision and is optimal for thinner metals up to 0.5 inches, delivering clean, intricate cuts with minimal kerf width. Plasma cutting handles thicker metals effectively, often cutting steel plates up to 2 inches or more with faster processing times but with less finesse and wider kerf. Choosing between laser and plasma cutting depends on the metal thickness and the required cut quality, where laser suits fine detail on thin sheets and plasma is preferred for robust, thick materials.

Operational Costs and Maintenance Differences

Laser cutting typically incurs higher initial equipment costs but offers lower operational expenses due to minimal consumable use and faster precision cutting. Plasma cutting has reduced upfront investment but demands more frequent consumable replacements, such as electrodes and nozzles, increasing maintenance frequency and costs. Maintenance for laser systems often involves periodic optic cleaning and alignment, whereas plasma systems require regular torch inspections and consumable management to maintain cutting performance.

Safety Considerations in Metal Cutting

Laser cutting offers enhanced safety due to its precise, focused beam reducing the risk of material distortion and minimizing hazardous fumes compared to plasma cutting, which generates intense heat and substantial smoke requiring robust ventilation systems. Plasma cutting poses higher risks of electric shock and UV radiation exposure, demanding operators use comprehensive protective gear, including insulated gloves and face shields. Proper safety protocols for both methods include maintaining clear work areas, ensuring equipment grounding, and using automated controls to limit direct human exposure to cutting arcs.

Choosing the Right Method for Your Metal Project

Laser cutting offers superior precision and clean edges for thin to medium-thickness metals, making it ideal for detailed designs and intricate patterns. Plasma cutting excels in cutting thicker metals quickly and cost-effectively, suitable for industrial projects requiring high productivity on steel, stainless steel, and aluminum. Selecting the right method depends on metal thickness, desired edge quality, and project complexity to ensure optimal efficiency and finish.

Laser Cutting vs Plasma Cutting Infographic

materialdif.com

materialdif.com