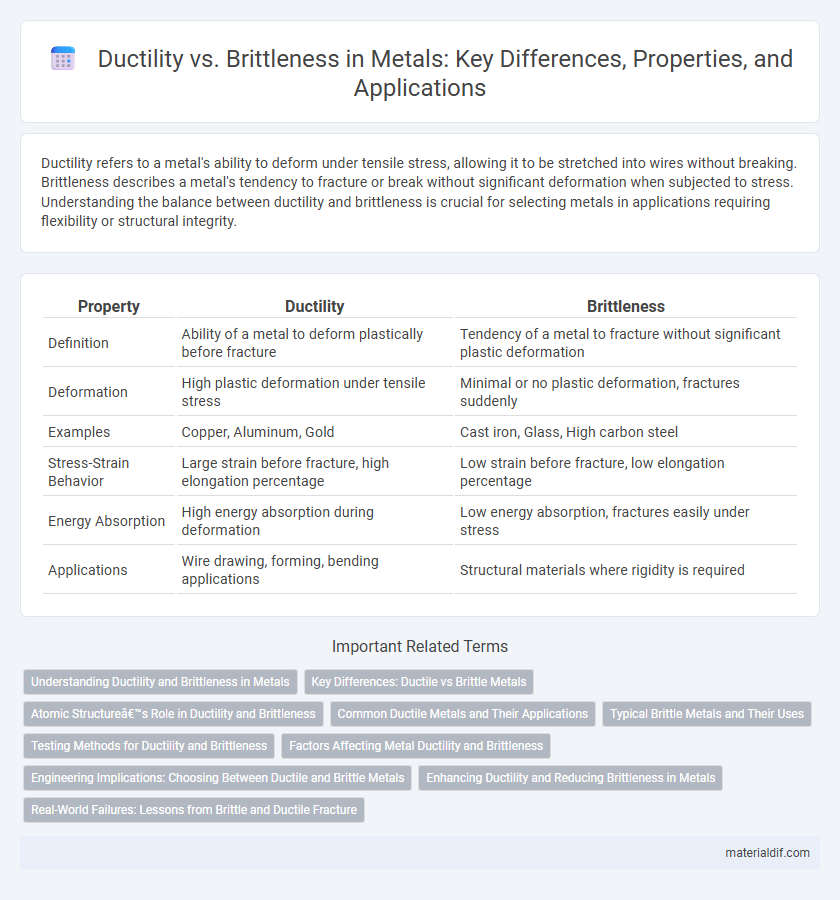

Ductility refers to a metal's ability to deform under tensile stress, allowing it to be stretched into wires without breaking. Brittleness describes a metal's tendency to fracture or break without significant deformation when subjected to stress. Understanding the balance between ductility and brittleness is crucial for selecting metals in applications requiring flexibility or structural integrity.

Table of Comparison

| Property | Ductility | Brittleness |

|---|---|---|

| Definition | Ability of a metal to deform plastically before fracture | Tendency of a metal to fracture without significant plastic deformation |

| Deformation | High plastic deformation under tensile stress | Minimal or no plastic deformation, fractures suddenly |

| Examples | Copper, Aluminum, Gold | Cast iron, Glass, High carbon steel |

| Stress-Strain Behavior | Large strain before fracture, high elongation percentage | Low strain before fracture, low elongation percentage |

| Energy Absorption | High energy absorption during deformation | Low energy absorption, fractures easily under stress |

| Applications | Wire drawing, forming, bending applications | Structural materials where rigidity is required |

Understanding Ductility and Brittleness in Metals

Ductility in metals refers to the ability to undergo significant plastic deformation before fracture, allowing materials like copper and aluminum to be drawn into wires without breaking. Brittleness describes the tendency of metals such as cast iron and glass to fracture with little to no plastic deformation, often resulting in sudden failure under stress. Understanding the balance between ductility and brittleness is crucial for selecting metals in applications requiring either flexibility or strength under impact.

Key Differences: Ductile vs Brittle Metals

Ductile metals, such as copper and aluminum, exhibit significant plastic deformation before fracture, allowing them to be stretched into wires or thin sheets without breaking. In contrast, brittle metals like cast iron and glass fracture suddenly under stress with minimal plastic deformation, leading to abrupt failure. The key difference lies in their atomic structure and bonding, where ductile metals have more dislocation movement enabling deformation, while brittle metals have limited slip systems causing them to crack under stress.

Atomic Structure’s Role in Ductility and Brittleness

The atomic structure of metals directly influences their ductility and brittleness by determining how atoms slide past each other under stress. Metals with a face-centered cubic (FCC) lattice structure allow more slip systems, enhancing ductility and enabling extensive plastic deformation. In contrast, body-centered cubic (BCC) and hexagonal close-packed (HCP) structures have fewer active slip systems at room temperature, leading to higher brittleness and a greater tendency to fracture under stress.

Common Ductile Metals and Their Applications

Common ductile metals such as copper, aluminum, and mild steel exhibit high plastic deformation before fracture, making them ideal for applications requiring flexibility and toughness. Copper's excellent electrical conductivity and malleability are essential in wiring and electronics, while aluminum's lightweight and corrosion resistance suit aerospace and automotive industries. Mild steel's balance of strength and ductility enables its widespread use in construction, automotive frames, and heavy machinery.

Typical Brittle Metals and Their Uses

Typical brittle metals such as cast iron, tungsten, and chromium exhibit low ductility, fracturing easily under stress without significant deformation. Cast iron is widely used in construction and automotive parts for its hardness and wear resistance, while tungsten's high melting point suits applications in electrical contacts and lighting filaments. Chromium's brittleness combined with corrosion resistance makes it ideal for protective coatings and stainless steel alloys.

Testing Methods for Ductility and Brittleness

Tensile testing is a primary method for evaluating ductility, measuring elongation and reduction in area to assess a metal's ability to deform plastically before fracture. Charpy impact tests quantify brittleness by determining the energy absorbed during fracture at high strain rates, highlighting the metal's resistance to sudden impacts. Bend tests also provide insight by revealing a metal's flexibility and propensity to crack under stress, essential for distinguishing ductile from brittle behavior.

Factors Affecting Metal Ductility and Brittleness

Temperature significantly influences metal ductility, with higher temperatures typically increasing ductility by allowing greater atomic mobility. Alloy composition impacts brittleness, as elements like carbon in steel can promote hardness but reduce ductility by forming brittle phases. Grain size also plays a crucial role; finer grains generally enhance ductility by impeding crack propagation, while coarser grains may lead to increased brittleness.

Engineering Implications: Choosing Between Ductile and Brittle Metals

Ductile metals like steel and aluminum deform significantly before fracture, making them ideal for applications requiring toughness and energy absorption in construction and automotive engineering. Brittle metals such as cast iron and certain ceramics fracture without noticeable deformation, offering high compressive strength but posing risks in structural components under tensile stress. Engineers must balance these properties to ensure safety and performance by selecting ductile metals for dynamic loads and brittle metals where rigidity and hardness are paramount.

Enhancing Ductility and Reducing Brittleness in Metals

Enhancing ductility in metals involves alloying with elements such as nickel or copper, which refine grain structure and improve atomic bonding, allowing the metal to deform more before fracturing. Techniques like annealing reduce internal stresses and increase dislocation mobility, thereby minimizing brittleness by preventing crack initiation under stress. Controlling cooling rates during metal processing also tailors microstructures to balance mechanical properties, optimizing ductility while suppressing brittle phases.

Real-World Failures: Lessons from Brittle and Ductile Fracture

Real-world failures in metals highlight critical differences between ductility and brittleness, where ductile fractures often exhibit significant plastic deformation before failure, allowing for warning signs such as stretching or necking. Brittle fractures, conversely, occur with minimal deformation and sudden crack propagation, frequently causing catastrophic failures in structures like bridges, pipelines, and aircraft components. Understanding fracture mechanics and microstructural influences helps engineers design safer materials by controlling ductility to prevent unexpected brittle fractures in critical applications.

Ductility vs Brittleness Infographic

materialdif.com

materialdif.com