Powder coating provides a durable, colorful finish that resists chipping, scratching, and fading, making it ideal for outdoor metal surfaces. Anodizing enhances the natural corrosion resistance of aluminum by forming a protective oxide layer, which also allows for subtle color options and increased surface hardness. Choosing between powder coating and anodizing depends on the desired aesthetic, environmental exposure, and durability requirements for the metal application.

Table of Comparison

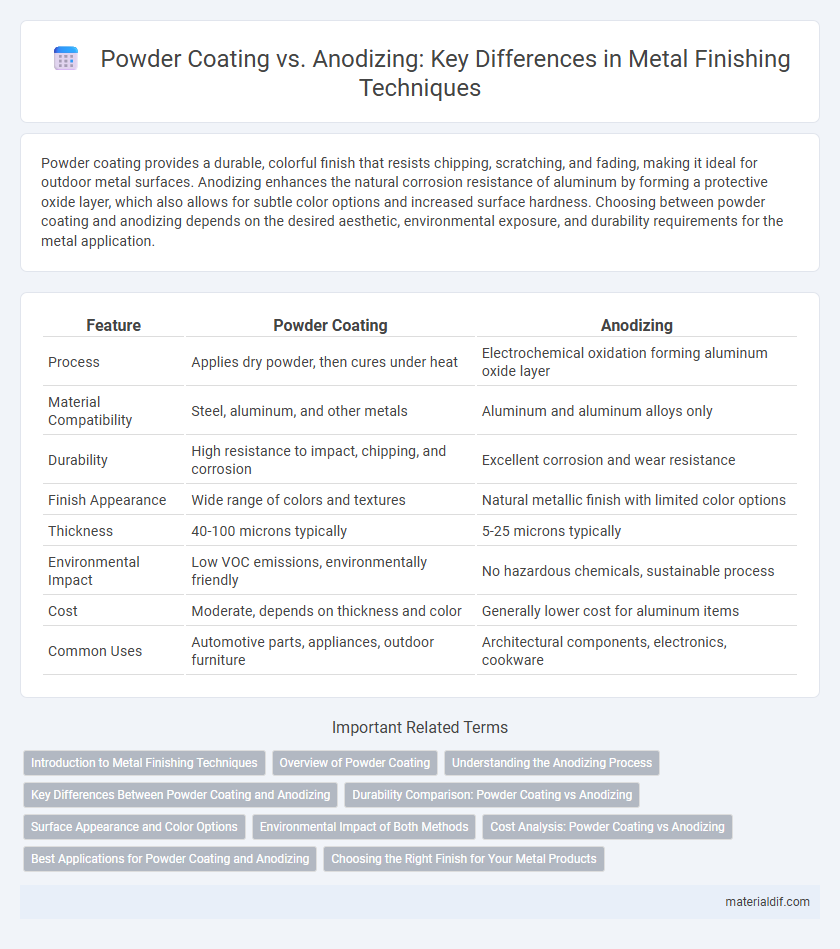

| Feature | Powder Coating | Anodizing |

|---|---|---|

| Process | Applies dry powder, then cures under heat | Electrochemical oxidation forming aluminum oxide layer |

| Material Compatibility | Steel, aluminum, and other metals | Aluminum and aluminum alloys only |

| Durability | High resistance to impact, chipping, and corrosion | Excellent corrosion and wear resistance |

| Finish Appearance | Wide range of colors and textures | Natural metallic finish with limited color options |

| Thickness | 40-100 microns typically | 5-25 microns typically |

| Environmental Impact | Low VOC emissions, environmentally friendly | No hazardous chemicals, sustainable process |

| Cost | Moderate, depends on thickness and color | Generally lower cost for aluminum items |

| Common Uses | Automotive parts, appliances, outdoor furniture | Architectural components, electronics, cookware |

Introduction to Metal Finishing Techniques

Powder coating and anodizing are essential metal finishing techniques that enhance durability and corrosion resistance. Powder coating involves applying a dry powder that is cured under heat to form a tough protective layer, ideal for aluminum, steel, and other metals. Anodizing, primarily used for aluminum, creates a thick oxide layer through electrochemical processes, improving surface hardness and aesthetic qualities.

Overview of Powder Coating

Powder coating is a dry finishing process that applies a protective and decorative layer to metal surfaces using a powdered polymer. This technique provides superior corrosion resistance, durability, and a wide range of color options compared to traditional liquid paints. Widely used in automotive, architectural, and industrial applications, powder coating ensures a uniform, high-quality finish that enhances metal's longevity and appearance.

Understanding the Anodizing Process

Anodizing enhances aluminum surfaces through an electrochemical process that converts the metal's surface into a durable, corrosion-resistant oxide layer, improving hardness and wear resistance. This oxide layer is porous, allowing for dyeing and sealing to achieve various colors and finishes, making anodizing ideal for architectural and automotive applications. Compared to powder coating, anodizing provides a thinner, more naturally bonded coating that resists chipping and peeling while maintaining metal breathability.

Key Differences Between Powder Coating and Anodizing

Powder coating involves the application of a dry powder polymer that is cured under heat to form a durable, protective layer on metal surfaces, while anodizing is an electrochemical process that converts the metal surface into a corrosion-resistant oxide layer, primarily used on aluminum. Powder coating provides thicker, more versatile color options and better impact resistance, whereas anodizing offers superior wear resistance and maintains the metal's natural metallic finish. Key differences include the application method, durability under different environmental conditions, and the appearance and texture of the final finish.

Durability Comparison: Powder Coating vs Anodizing

Powder coating offers a thick, protective layer that resists chipping, scratching, and corrosion, making it ideal for outdoor and industrial environments. Anodizing creates a permanent oxide layer on aluminum that enhances corrosion resistance and surface hardness but may be less effective on impact resistance compared to powder coating. Both methods extend metal lifespan, with powder coating excelling in durability against physical wear and anodizing providing superior chemical and UV resistance.

Surface Appearance and Color Options

Powder coating provides a thick, uniform finish with a wide range of vibrant color options, including matte, gloss, and textured surfaces, enhancing both aesthetic appeal and durability. Anodizing creates a natural, metallic finish with limited color variations, typically including shades of silver, black, and bronze, while maintaining the metal's original texture and improving corrosion resistance. Surface appearance in powder coating is more customizable and visually diverse, whereas anodizing offers a subtle, sleek look emphasizing the metal's inherent characteristics.

Environmental Impact of Both Methods

Powder coating significantly reduces volatile organic compound (VOC) emissions compared to traditional liquid coatings, making it a more environmentally friendly option in metal finishing. Anodizing uses an electrolytic process that consumes substantial energy and generates acidic wastewater, requiring careful treatment to prevent environmental contamination. Both methods offer durable finishes, but powder coating typically has a lower overall environmental footprint due to reduced hazardous waste and more efficient resource use.

Cost Analysis: Powder Coating vs Anodizing

Powder coating generally offers lower upfront equipment costs and faster application times compared to anodizing, which requires specialized electrolytic tanks and precise chemical controls, increasing initial capital investment. Operating expenses for powder coating include energy for curing ovens and regular maintenance, while anodizing involves ongoing expenses for acid baths, rinsing water, and hazardous waste disposal, contributing to higher treatment costs per unit. For large-scale or complex metal parts, powder coating often yields a more cost-effective solution, whereas anodizing provides a more durable finish but at a premium price point, influencing the total cost analysis based on project requirements.

Best Applications for Powder Coating and Anodizing

Powder coating excels in providing a durable, thick protective layer suitable for outdoor metal furniture, automotive parts, and industrial equipment where corrosion resistance and color variety are essential. Anodizing is ideal for aluminum components requiring enhanced surface hardness, improved wear resistance, and a natural metallic finish, commonly used in architectural panels, aerospace parts, and consumer electronics. Selecting between powder coating and anodizing depends on factors like material type, environmental exposure, and desired aesthetic, with powder coating favored for steel and complex shapes, while anodizing is preferred for lightweight aluminum parts.

Choosing the Right Finish for Your Metal Products

Powder coating provides a durable, weather-resistant finish ideal for outdoor metal products, offering a wide range of colors and textures that enhance corrosion protection. Anodizing, commonly applied to aluminum, creates a hard, oxide layer that improves surface hardness and wear resistance while maintaining the metal's natural appearance. Selecting between powder coating and anodizing depends on factors such as environmental exposure, desired aesthetic, and the metal type, ensuring optimal performance and longevity for your metal products.

Powder Coating vs Anodizing Infographic

materialdif.com

materialdif.com