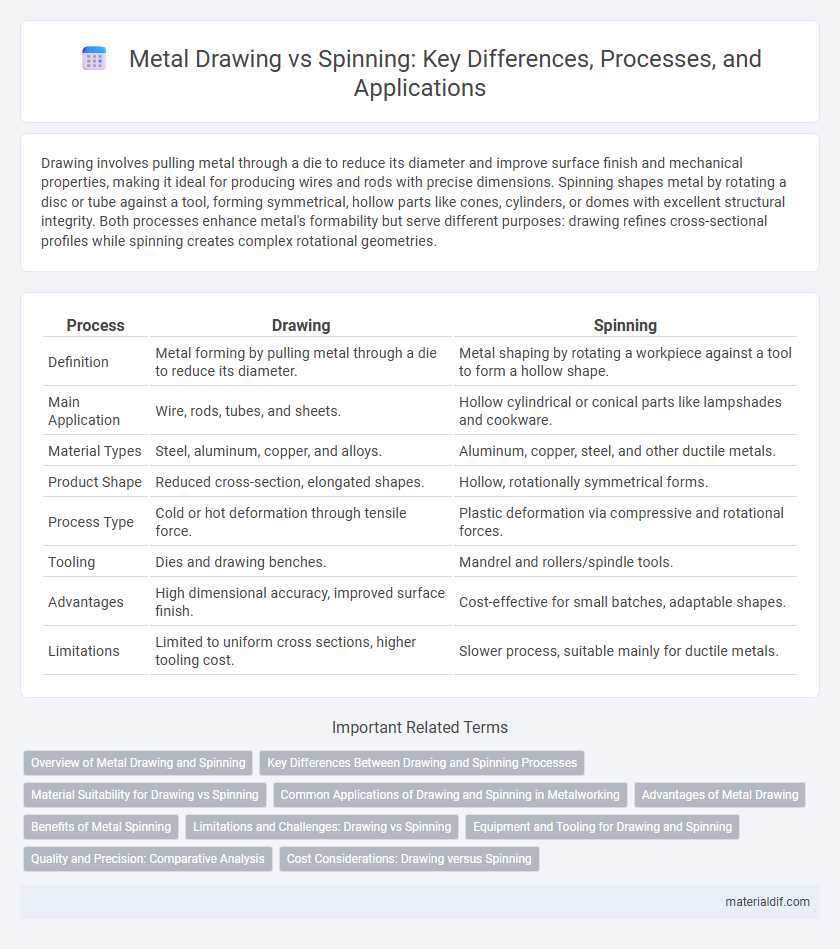

Drawing involves pulling metal through a die to reduce its diameter and improve surface finish and mechanical properties, making it ideal for producing wires and rods with precise dimensions. Spinning shapes metal by rotating a disc or tube against a tool, forming symmetrical, hollow parts like cones, cylinders, or domes with excellent structural integrity. Both processes enhance metal's formability but serve different purposes: drawing refines cross-sectional profiles while spinning creates complex rotational geometries.

Table of Comparison

| Process | Drawing | Spinning |

|---|---|---|

| Definition | Metal forming by pulling metal through a die to reduce its diameter. | Metal shaping by rotating a workpiece against a tool to form a hollow shape. |

| Main Application | Wire, rods, tubes, and sheets. | Hollow cylindrical or conical parts like lampshades and cookware. |

| Material Types | Steel, aluminum, copper, and alloys. | Aluminum, copper, steel, and other ductile metals. |

| Product Shape | Reduced cross-section, elongated shapes. | Hollow, rotationally symmetrical forms. |

| Process Type | Cold or hot deformation through tensile force. | Plastic deformation via compressive and rotational forces. |

| Tooling | Dies and drawing benches. | Mandrel and rollers/spindle tools. |

| Advantages | High dimensional accuracy, improved surface finish. | Cost-effective for small batches, adaptable shapes. |

| Limitations | Limited to uniform cross sections, higher tooling cost. | Slower process, suitable mainly for ductile metals. |

Overview of Metal Drawing and Spinning

Metal drawing involves pulling metal through a die to reduce its diameter and increase length, commonly used for wires, rods, and tubes, enhancing tensile strength and surface finish. Metal spinning shapes flat metal discs into symmetrical hollow forms by rotating them on a lathe and pressing with tools, ideal for producing seamless, round components like pots, cones, and cylinders. Drawing emphasizes dimensional accuracy and strength, while spinning excels in creating complex, hollow shapes with a smooth surface.

Key Differences Between Drawing and Spinning Processes

Drawing involves pulling metal through a die to reduce its diameter and increase length, enhancing surface finish and mechanical strength, while spinning is a metal forming process where a flat metal disc or tube is rotated at high speed and shaped over a mandrel to create symmetric, hollow components. Drawing primarily affects the metal's tensile properties and dimensional accuracy, whereas spinning allows complex geometries with minimal material waste and internal stress. Material thickness reduction is significant in drawing, while spinning focuses on contour forming without necessarily altering thickness.

Material Suitability for Drawing vs Spinning

Drawing is highly suitable for metals with high ductility such as copper, aluminum, and low-carbon steel, enabling the formation of precise wire and sheet shapes through tensile deformation. Spinning works best with metals like aluminum, brass, and mild steel that exhibit good formability and can withstand compressive stresses without cracking. The choice between drawing and spinning depends on the metal's ability to endure tensile versus compressive forces during shaping processes.

Common Applications of Drawing and Spinning in Metalworking

Drawing is commonly used in metalworking to produce wires, rods, and tubes with precise dimensions and smooth surface finishes, essential for electrical wiring, automotive components, and structural materials. Spinning is widely applied to create symmetrical, hollow metal parts such as cookware, musical instruments, and aerospace components, benefiting industries that require lightweight yet strong circular shapes. Both techniques optimize metal deformation processes to enhance material properties and achieve complex shapes in manufacturing.

Advantages of Metal Drawing

Metal drawing improves dimensional accuracy and surface finish compared to spinning, making it ideal for producing precise, intricate shapes. It enhances mechanical properties by inducing work hardening, resulting in stronger and more durable components. Drawing also offers greater control over thickness and uniformity, reducing material waste in manufacturing processes.

Benefits of Metal Spinning

Metal spinning offers superior precision and consistency in forming complex, symmetrical shapes, making it ideal for manufacturing high-quality, seamless cylindrical components. This process ensures minimal material waste and reduced production costs compared to drawing, while enhancing mechanical properties through controlled work hardening. Its flexibility allows for rapid prototyping and efficient mass production of custom metal parts with smooth surface finishes.

Limitations and Challenges: Drawing vs Spinning

Drawing faces limitations such as reduced ductility and increased work hardening, which restrict the extent of deformation and may require intermediate annealing steps to restore metal properties. Spinning challenges include achieving uniform thickness and maintaining dimensional accuracy, especially for complex shapes or when working with harder alloys. Both processes demand careful control of parameters like temperature and strain rate to minimize defects and optimize final product quality.

Equipment and Tooling for Drawing and Spinning

Drawing in metalworking relies heavily on precision dies and drawing benches equipped with powerful tonnage capacity to pull metal through reducing its diameter, requiring tools like draw plates, wire drawing machines, and lubrication systems to minimize friction. Spinning demands a robust spinning lathe or mandrel that supports the metal blank while a roller or spoon tool shapes it against a form, with tooling typically including specialized rollers, spindles, and adjustable chucks to maintain consistent pressure and accurate profiles. Equipment for drawing emphasizes tensile force and die quality, whereas spinning tooling prioritizes control of metal flow and surface finish through skilled hand or automated tool manipulation.

Quality and Precision: Comparative Analysis

Drawing metal enhances surface finish and dimensional accuracy by stretching the material through dies, resulting in finer grain structure and tighter tolerances. Spinning metal, which involves rotating the workpiece against a tool, offers flexibility in shaping but may introduce minor surface irregularities and less uniform thickness. For applications demanding superior quality and precision, drawing provides more consistent results, while spinning suits more complex, less precision-critical geometries.

Cost Considerations: Drawing versus Spinning

Drawing metal involves pulling the material through dies to achieve desired shapes, typically incurring higher costs due to tooling wear and energy consumption. Spinning, which forms metal by rotating and shaping it on a lathe, generally offers lower production costs for low to medium volume runs due to reduced tooling expenses. Selecting between drawing and spinning hinges on balancing the initial setup investment with per-unit manufacturing costs and production volume.

Drawing vs Spinning Infographic

materialdif.com

materialdif.com