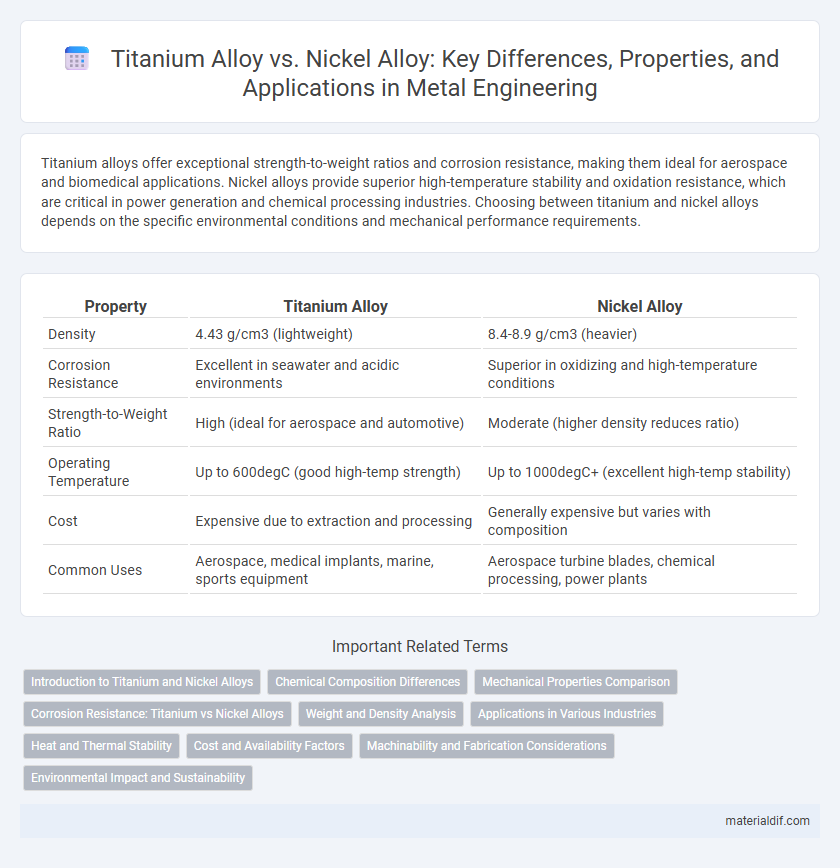

Titanium alloys offer exceptional strength-to-weight ratios and corrosion resistance, making them ideal for aerospace and biomedical applications. Nickel alloys provide superior high-temperature stability and oxidation resistance, which are critical in power generation and chemical processing industries. Choosing between titanium and nickel alloys depends on the specific environmental conditions and mechanical performance requirements.

Table of Comparison

| Property | Titanium Alloy | Nickel Alloy |

|---|---|---|

| Density | 4.43 g/cm3 (lightweight) | 8.4-8.9 g/cm3 (heavier) |

| Corrosion Resistance | Excellent in seawater and acidic environments | Superior in oxidizing and high-temperature conditions |

| Strength-to-Weight Ratio | High (ideal for aerospace and automotive) | Moderate (higher density reduces ratio) |

| Operating Temperature | Up to 600degC (good high-temp strength) | Up to 1000degC+ (excellent high-temp stability) |

| Cost | Expensive due to extraction and processing | Generally expensive but varies with composition |

| Common Uses | Aerospace, medical implants, marine, sports equipment | Aerospace turbine blades, chemical processing, power plants |

Introduction to Titanium and Nickel Alloys

Titanium alloys exhibit exceptional strength-to-weight ratios, excellent corrosion resistance, and superior biocompatibility, making them essential in aerospace, medical, and marine industries. Nickel alloys are valued for their high-temperature stability, oxidation resistance, and durability in harsh environments, often used in power generation and chemical processing. Both metals offer unique properties tailored to specific engineering applications, with titanium alloys favored for lightweight performance and nickel alloys preferred for thermal and chemical resilience.

Chemical Composition Differences

Titanium alloys primarily consist of titanium combined with elements like aluminum, vanadium, and molybdenum, enhancing strength and corrosion resistance while maintaining low density. Nickel alloys contain a high percentage of nickel with chromium, iron, and sometimes molybdenum, providing exceptional oxidation resistance and high-temperature stability. The key chemical difference lies in titanium alloys' lighter elemental base compared to nickel alloys' focus on nickel and chromium for thermal endurance and corrosion resistance.

Mechanical Properties Comparison

Titanium alloys exhibit superior strength-to-weight ratios and excellent corrosion resistance compared to nickel alloys, making them ideal for aerospace and biomedical applications. Nickel alloys, however, demonstrate higher temperature resistance and better creep strength, which are essential in high-temperature environments like gas turbines and chemical processing. Mechanical properties such as tensile strength, fatigue resistance, and hardness vary depending on specific alloy compositions but generally highlight titanium's lightweight durability versus nickel's heat tolerance.

Corrosion Resistance: Titanium vs Nickel Alloys

Titanium alloys exhibit superior corrosion resistance due to their stable oxide film, which effectively protects against oxidation and chemical attacks in harsh environments such as seawater and acidic conditions. Nickel alloys also offer excellent corrosion resistance, especially in high-temperature and oxidizing environments, but they can be susceptible to localized corrosion like pitting and stress corrosion cracking in chloride-rich environments. The choice between titanium and nickel alloys hinges on specific application requirements, with titanium favored for extreme resistance to corrosion and nickel alloys preferred for strength and durability under high thermal stress.

Weight and Density Analysis

Titanium alloys have a density of approximately 4.5 g/cm3, which is significantly lower than nickel alloys, typically around 8.9 g/cm3, making titanium alloys nearly 50% lighter. This reduced weight contributes to improved strength-to-weight ratios, crucial for aerospace and automotive applications where weight savings enhance fuel efficiency and performance. Nickel alloys, while denser, offer superior corrosion and heat resistance but come with the trade-off of increased structural weight.

Applications in Various Industries

Titanium alloys are widely used in aerospace and biomedical industries due to their high strength-to-weight ratio and excellent corrosion resistance, making them ideal for aircraft components and medical implants. Nickel alloys excel in chemical processing and power generation sectors because of their superior heat resistance and durability in harsh environments such as gas turbines and heat exchangers. Both materials serve critical roles in marine applications, but titanium alloys are preferred for their resistance to seawater corrosion, whereas nickel alloys are chosen for their mechanical strength at elevated temperatures.

Heat and Thermal Stability

Titanium alloys exhibit exceptional heat resistance and thermal stability, maintaining mechanical integrity at temperatures up to 600degC due to their strong oxide layer and low thermal conductivity. Nickel alloys outperform titanium in extreme high-temperature environments, withstanding temperatures beyond 1000degC while preserving corrosion resistance and structural strength. These properties make nickel alloys ideal for aerospace turbine components, whereas titanium alloys are preferred for moderately high-temperature applications demanding lightweight performance.

Cost and Availability Factors

Titanium alloys generally incur higher costs due to complex extraction and processing methods, but their superior strength-to-weight ratio justifies the investment in aerospace and medical applications. Nickel alloys, while more affordable and widely available, offer excellent corrosion resistance and thermal stability, making them ideal for industrial and automotive uses. Market availability for titanium alloys is limited compared to the more abundant nickel alloys, influencing material selection based on budget constraints and application demands.

Machinability and Fabrication Considerations

Titanium alloys exhibit lower machinability compared to nickel alloys due to their high strength and affinity for tool wear, necessitating specialized cutting tools and slower machining speeds. Nickel alloys offer superior fabrication ease with better shear strength and thermal conductivity, allowing faster machining and reduced tooling costs. Selecting titanium or nickel alloys depends on balancing machinability with performance requirements in aerospace and medical applications.

Environmental Impact and Sustainability

Titanium alloys offer superior corrosion resistance and biocompatibility, resulting in longer lifespan and reduced need for frequent replacement, which minimizes environmental waste. Nickel alloys, while durable and corrosion-resistant, typically require more energy-intensive mining and refining processes, leading to higher carbon emissions and greater ecological disturbance. Sustainable applications favor titanium alloys due to their recyclability and lower toxicity during manufacturing and disposal phases.

Titanium Alloy vs Nickel Alloy Infographic

materialdif.com

materialdif.com