Hardness measures a metal's resistance to surface deformation or scratching, indicating its ability to withstand wear and abrasion. Toughness reflects a metal's capacity to absorb energy and deform plastically before fracturing, highlighting its resistance to impact and shock. Balancing hardness and toughness is essential in metal selection to ensure durability without brittleness.

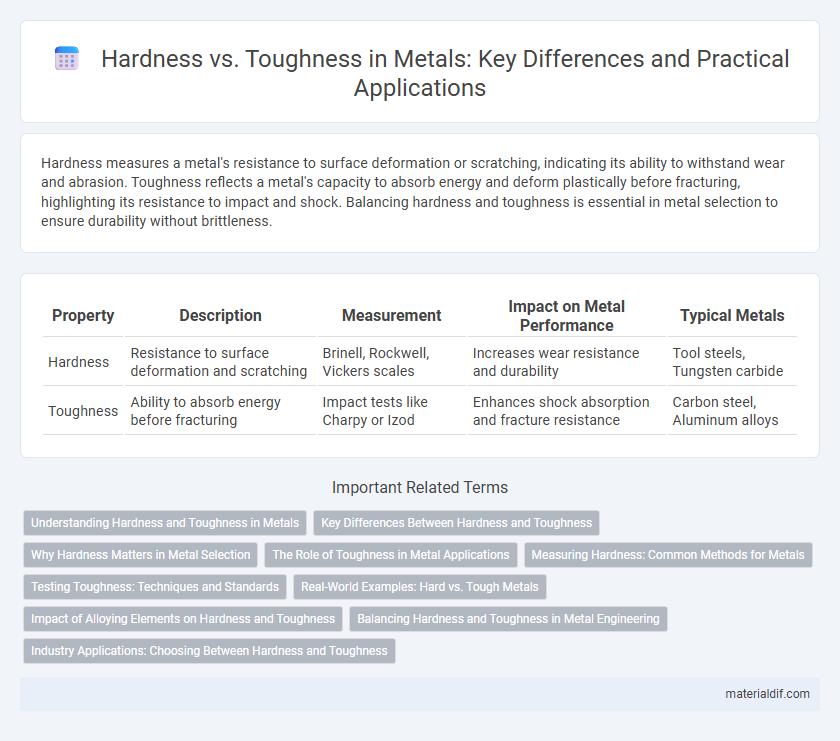

Table of Comparison

| Property | Description | Measurement | Impact on Metal Performance | Typical Metals |

|---|---|---|---|---|

| Hardness | Resistance to surface deformation and scratching | Brinell, Rockwell, Vickers scales | Increases wear resistance and durability | Tool steels, Tungsten carbide |

| Toughness | Ability to absorb energy before fracturing | Impact tests like Charpy or Izod | Enhances shock absorption and fracture resistance | Carbon steel, Aluminum alloys |

Understanding Hardness and Toughness in Metals

Hardness in metals refers to their resistance to deformation, indentation, or scratching, often measured by scales such as Mohs, Vickers, or Rockwell. Toughness describes a metal's ability to absorb energy and plastically deform without fracturing, combining strength and ductility to resist impact and shock. Understanding the balance between hardness and toughness is crucial for selecting metals in applications requiring wear resistance and durability, such as cutting tools and structural components.

Key Differences Between Hardness and Toughness

Hardness measures a metal's resistance to deformation or surface indentation, typically evaluated by tests like Brinell, Rockwell, or Vickers. Toughness quantifies a metal's ability to absorb energy and plastically deform without fracturing, indicating its resistance to impact and crack propagation. While hardness emphasizes surface durability, toughness reflects overall structural resilience under dynamic loading conditions.

Why Hardness Matters in Metal Selection

Hardness in metal selection is crucial because it determines resistance to surface deformation, wear, and scratching, directly affecting the lifespan and durability of components. Metals with high hardness are essential for applications subjected to abrasive forces and heavy loads, ensuring structural integrity under stress. Selecting the appropriate hardness level balances performance and cost, optimizing metal usage in manufacturing and engineering processes.

The Role of Toughness in Metal Applications

Toughness in metals is a critical property that measures a material's ability to absorb energy and plastically deform without fracturing, making it essential for applications subjected to impact and sudden forces. Unlike hardness, which assesses resistance to surface indentation or scratching, toughness determines a metal's capacity to withstand shock and prevent catastrophic failure. In industries such as automotive, aerospace, and construction, metals with high toughness ensure durability and safety by resisting crack propagation under dynamic loading conditions.

Measuring Hardness: Common Methods for Metals

Measuring hardness in metals commonly involves methods such as the Rockwell, Brinell, and Vickers tests, each designed to assess resistance to indentation under specific load conditions. The Rockwell hardness test uses a steel ball or diamond cone indenter with a minor and major load to quickly determine hardness scales like HRB or HRC, making it suitable for quality control. Brinell testing employs a larger steel ball under heavy loads to evaluate surface hardness, ideal for coarse materials, while Vickers uses a diamond pyramid indenter providing precise measurements for thin sections and small parts.

Testing Toughness: Techniques and Standards

Testing toughness in metals involves methods such as Charpy and Izod impact tests, which measure the material's ability to absorb energy during plastic deformation. Standards like ASTM E23 and ISO 148 specify testing procedures to ensure consistency in toughness measurement across different metal alloys. These techniques provide critical data to predict metal performance under dynamic loading and impact conditions.

Real-World Examples: Hard vs. Tough Metals

Hard metals like tungsten carbide resist scratches and wear, making them ideal for cutting tools and industrial machinery exposed to abrasive conditions. Tough metals such as titanium alloys absorb significant impacts without breaking, commonly used in aerospace and automotive applications where durability under stress is critical. Steel alloys represent a balance, offering moderate hardness and toughness, widely applied in construction and manufacturing for versatile performance.

Impact of Alloying Elements on Hardness and Toughness

Alloying elements such as chromium, nickel, and molybdenum significantly influence the hardness and toughness of metals by altering their microstructure and phase composition. Chromium increases hardness and corrosion resistance through the formation of hard carbides, while nickel enhances toughness by improving ductility and impact strength. Molybdenum contributes to higher hardness without compromising toughness by refining grain size and stabilizing desirable phases in steel alloys.

Balancing Hardness and Toughness in Metal Engineering

Balancing hardness and toughness in metal engineering requires optimizing alloy composition and heat treatment processes to achieve a material that resists deformation while absorbing impact energy. Hardness improves wear resistance in components like cutting tools and gears, whereas toughness ensures durability under dynamic loads and prevents brittle fracture in structural applications. Advanced techniques such as quenching and tempering enable engineers to tailor microstructures, creating steels that maintain an effective equilibrium between these critical mechanical properties.

Industry Applications: Choosing Between Hardness and Toughness

In industrial applications, selecting between hardness and toughness depends on the operational demands of the metal component. Hardness is essential for wear resistance in cutting tools and machining parts, where surface durability extends service life. Toughness is prioritized in structural components and impact-resistant parts, ensuring the material absorbs energy without fracturing under sudden loads.

Hardness vs Toughness Infographic

materialdif.com

materialdif.com