304 stainless steel offers excellent corrosion resistance and is widely used in kitchen appliances and automotive parts, but 316 stainless steel contains molybdenum, enhancing its resistance to chloride corrosion, making it ideal for marine and chemical environments. Both grades provide durability and strength, but 316 stainless steel performs better in harsh conditions where exposure to saltwater or aggressive chemicals is common. Choosing between 304 and 316 stainless steel depends on the specific environmental demands and cost considerations.

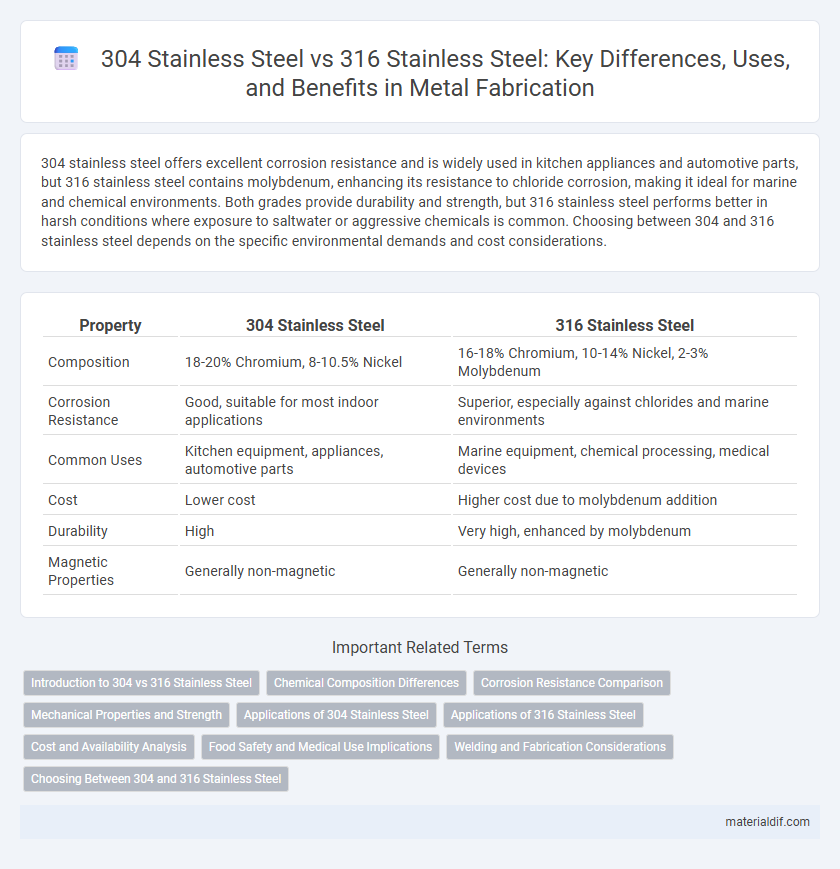

Table of Comparison

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Composition | 18-20% Chromium, 8-10.5% Nickel | 16-18% Chromium, 10-14% Nickel, 2-3% Molybdenum |

| Corrosion Resistance | Good, suitable for most indoor applications | Superior, especially against chlorides and marine environments |

| Common Uses | Kitchen equipment, appliances, automotive parts | Marine equipment, chemical processing, medical devices |

| Cost | Lower cost | Higher cost due to molybdenum addition |

| Durability | High | Very high, enhanced by molybdenum |

| Magnetic Properties | Generally non-magnetic | Generally non-magnetic |

Introduction to 304 vs 316 Stainless Steel

304 stainless steel contains 18-20% chromium and 8-10.5% nickel, offering excellent corrosion resistance and versatility for general applications. 316 stainless steel includes 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, enhancing resistance to chlorides and marine environments. The addition of molybdenum in 316 provides superior protection against pitting and crevice corrosion compared to 304.

Chemical Composition Differences

304 stainless steel primarily consists of 18-20% chromium and 8-10.5% nickel, while 316 stainless steel contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The addition of molybdenum in 316 enhances corrosion resistance, especially against chlorides and industrial solvents. These chemical composition differences make 316 suitable for more aggressive environments compared to 304.

Corrosion Resistance Comparison

304 stainless steel offers good corrosion resistance in many environments but is less effective against chlorides and marine conditions. 316 stainless steel contains molybdenum, significantly enhancing its resistance to pitting and crevice corrosion, especially in saltwater and chemical exposure. This makes 316 stainless steel the preferred choice for applications requiring superior corrosion resistance in harsh environments.

Mechanical Properties and Strength

304 stainless steel offers excellent tensile strength of approximately 75,000 psi and yield strength around 30,000 psi, making it suitable for standard structural applications. In comparison, 316 stainless steel exhibits slightly higher tensile strength near 80,000 psi and improved yield strength about 35,000 psi, attributed to its molybdenum content enhancing corrosion resistance and mechanical performance. Both grades maintain good ductility and impact resistance, but 316 stainless steel's superior strength and mechanical properties make it preferable for harsher environments and heavy-duty applications.

Applications of 304 Stainless Steel

304 stainless steel is extensively used in kitchen equipment, food processing, and architectural applications due to its excellent corrosion resistance and ease of fabrication. Its resistance to oxidation and acid attack makes it ideal for manufacturing sinks, storage tanks, and chemical containers. The material's affordability and versatility also support its widespread use in automotive trim and industrial machinery components.

Applications of 316 Stainless Steel

316 stainless steel is widely used in marine environments, chemical processing, and medical devices due to its superior corrosion resistance and enhanced durability compared to 304 stainless steel. Its high molybdenum content provides excellent resistance to chloride-induced pitting and crevice corrosion, making it ideal for saltwater and aggressive chemical exposure. This makes 316 stainless steel the material of choice for applications such as boat fittings, pharmaceutical equipment, and food processing machinery.

Cost and Availability Analysis

304 stainless steel is generally more cost-effective and widely available due to its extensive production and usage in various industries, making it the preferred choice for budget-sensitive projects. In contrast, 316 stainless steel, containing molybdenum for enhanced corrosion resistance, commands a higher price and may face limited availability depending on region and market demand. The price difference between 304 and 316 stainless steel typically ranges between 20% to 50%, impacting procurement decisions where cost and accessibility are critical factors.

Food Safety and Medical Use Implications

304 Stainless Steel offers excellent corrosion resistance and is widely used in food processing equipment due to its affordability and ability to withstand mild acidic environments. 316 Stainless Steel contains molybdenum, providing superior resistance to chlorides and saline solutions, making it ideal for medical instruments and implants exposed to bodily fluids. Both grades meet FDA regulations for food safety, but 316 is preferred in applications requiring enhanced biocompatibility and sterilization resilience.

Welding and Fabrication Considerations

304 stainless steel offers excellent weldability with minimal risk of carbide precipitation, making it ideal for most fabrication methods. 316 stainless steel contains molybdenum, enhancing corrosion resistance but requires careful heat control during welding to prevent sensitization. Both alloys benefit from post-weld annealing in critical applications to restore corrosion resistance and mechanical properties.

Choosing Between 304 and 316 Stainless Steel

Choosing between 304 and 316 stainless steel depends on corrosion resistance and application environment; 316 stainless steel contains molybdenum, which enhances its resistance to chloride and marine environments compared to 304. For indoor applications or less harsh environments, 304 stainless steel offers excellent durability and cost-effectiveness. In contrast, 316 stainless steel is preferred for chemical processing, coastal, or high-salinity conditions due to its superior resistance to pitting and crevice corrosion.

304 Stainless Steel vs 316 Stainless Steel Infographic

materialdif.com

materialdif.com