Martensite and austenite are two fundamental microstructures in steel with distinct properties and applications. Martensite, formed by rapid cooling, is hard and brittle due to its body-centered tetragonal structure, making it ideal for wear-resistant tools. Austenite, stable at high temperatures with a face-centered cubic structure, offers greater ductility and toughness, commonly used in stainless steels and heat-resistant alloys.

Table of Comparison

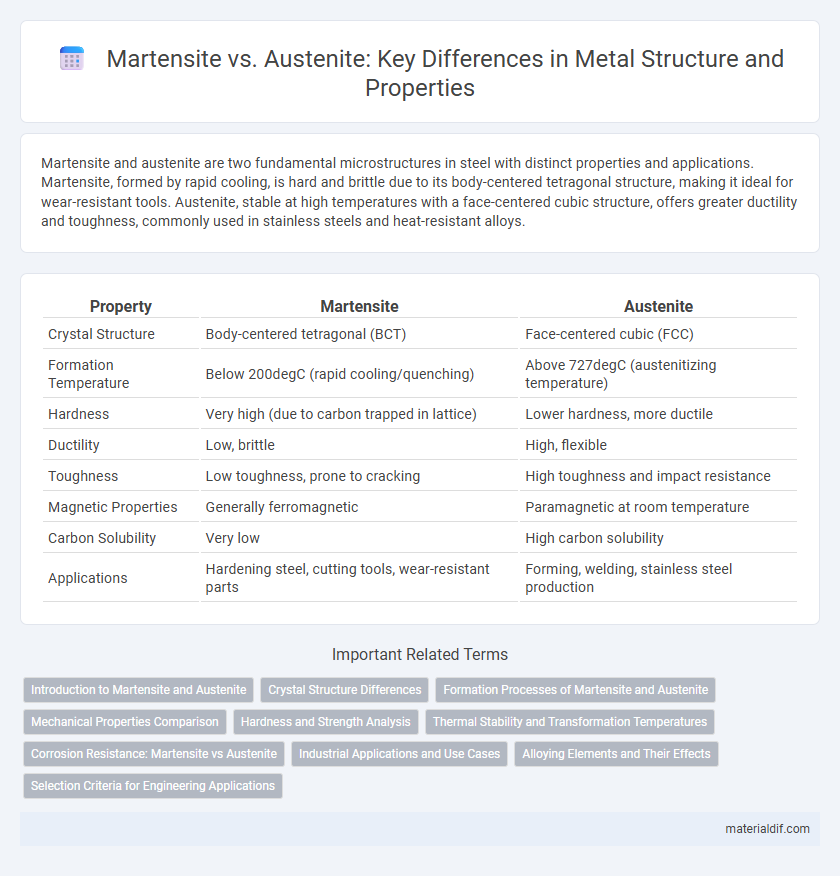

| Property | Martensite | Austenite |

|---|---|---|

| Crystal Structure | Body-centered tetragonal (BCT) | Face-centered cubic (FCC) |

| Formation Temperature | Below 200degC (rapid cooling/quenching) | Above 727degC (austenitizing temperature) |

| Hardness | Very high (due to carbon trapped in lattice) | Lower hardness, more ductile |

| Ductility | Low, brittle | High, flexible |

| Toughness | Low toughness, prone to cracking | High toughness and impact resistance |

| Magnetic Properties | Generally ferromagnetic | Paramagnetic at room temperature |

| Carbon Solubility | Very low | High carbon solubility |

| Applications | Hardening steel, cutting tools, wear-resistant parts | Forming, welding, stainless steel production |

Introduction to Martensite and Austenite

Martensite is a hard, brittle phase formed in steel during rapid cooling, characterized by a distorted body-centered tetragonal crystal structure. Austenite, also known as gamma iron, is a face-centered cubic phase stable at high temperatures and capable of dissolving more carbon. The transformation between these phases significantly affects the mechanical properties of steels used in construction and manufacturing.

Crystal Structure Differences

Martensite exhibits a body-centered tetragonal (BCT) crystal structure formed by rapid quenching, resulting in a distorted lattice compared to the face-centered cubic (FCC) structure of austenite. The BCT arrangement in martensite creates high internal stresses and hardness due to carbon atoms trapped in interstitial sites, unlike the more stable and ductile FCC structure in austenite. These crystal structure differences directly influence mechanical properties, with martensite providing superior strength and austenite offering greater toughness and formability.

Formation Processes of Martensite and Austenite

Martensite forms through a diffusionless transformation when steel is rapidly cooled from the austenitizing temperature, causing a shear-dominant rearrangement of the iron crystal structure into a body-centered tetragonal form. Austenite develops during heating when steel is held above the critical temperature, enabling atoms to rearrange into a face-centered cubic lattice through a diffusion-controlled process. The distinct formation mechanisms directly influence the mechanical properties and microstructure stability of steel alloys.

Mechanical Properties Comparison

Martensite exhibits higher hardness and tensile strength due to its supersaturated carbon content and distorted lattice structure, making it ideal for wear-resistant applications. Austenite offers superior toughness and ductility, maintaining excellent impact resistance even at low temperatures because of its face-centered cubic (FCC) crystal structure. The contrasting mechanical properties of martensite and austenite are critical in steel heat treatment processes to balance strength and toughness for specific engineering demands.

Hardness and Strength Analysis

Martensite exhibits significantly higher hardness and strength compared to austenite due to its supersaturated carbon content and distorted body-centered tetragonal crystal structure. Austenite, characterized by a face-centered cubic lattice, offers lower hardness but greater ductility and toughness, making it less resistant to deformation under stress. The transformation from austenite to martensite during rapid cooling (quenching) drastically enhances mechanical properties, crucial for wear-resistant and high-strength steel applications.

Thermal Stability and Transformation Temperatures

Martensite exhibits high thermal stability at lower temperatures, maintaining its hardness but begins transforming to austenite as temperatures approach the critical transformation range, typically between 200degC and 400degC depending on alloy composition. Austenite remains stable at elevated temperatures, generally above 727degC in steel, where it exists as a face-centered cubic (FCC) phase and allows for enhanced ductility and toughness. The precise transformation temperatures vary based on alloying elements, with carbon content significantly lowering the martensite start (Ms) temperature and promoting retention of austenite at room temperature.

Corrosion Resistance: Martensite vs Austenite

Martensite exhibits lower corrosion resistance compared to austenite due to its high carbon content and tetragonal crystal structure, which make it more susceptible to localized corrosion. Austenitic stainless steels contain higher levels of chromium and nickel, providing superior passivation and enhanced resistance to pitting and crevice corrosion. Consequently, austenite is preferred in environments requiring high corrosion resistance, such as marine and chemical processing applications.

Industrial Applications and Use Cases

Martensite's high hardness and strength make it ideal for applications requiring wear resistance, such as cutting tools, automotive components, and ball bearings. Austenite, featuring excellent corrosion resistance and toughness, is commonly used in stainless steel manufacturing for chemical processing equipment, food industry machinery, and medical implants. The choice between martensite and austenite hinges on balancing mechanical strength versus corrosion resistance in industrial material selection.

Alloying Elements and Their Effects

Martensite forms in steels through rapid cooling and is characterized by a hard, brittle microstructure with high carbon content trapped in a body-centered tetragonal lattice, while austenite has a face-centered cubic structure stabilized at higher temperatures. Alloying elements like chromium, nickel, and manganese influence the transformation temperatures and phase stability, with nickel promoting austenite formation and chromium enhancing martensite hardness by increasing carbon solubility. Elements such as molybdenum and silicon improve the toughness and corrosion resistance of martensitic steels, whereas carbon content directly affects the hardness and strength of martensite but reduces ductility in austenite.

Selection Criteria for Engineering Applications

Martensite offers exceptional hardness and strength, making it ideal for wear-resistant components and cutting tools, while Austenite provides superior ductility and corrosion resistance suitable for structural and cryogenic applications. Engineers select Martensite when high tensile strength and toughness are critical, whereas Austenite is preferred for environments demanding enhanced formability and stability at low temperatures. The choice depends on balancing mechanical properties, corrosion resistance, and thermal exposure to meet specific performance requirements.

Martensite vs Austenite Infographic

materialdif.com

materialdif.com