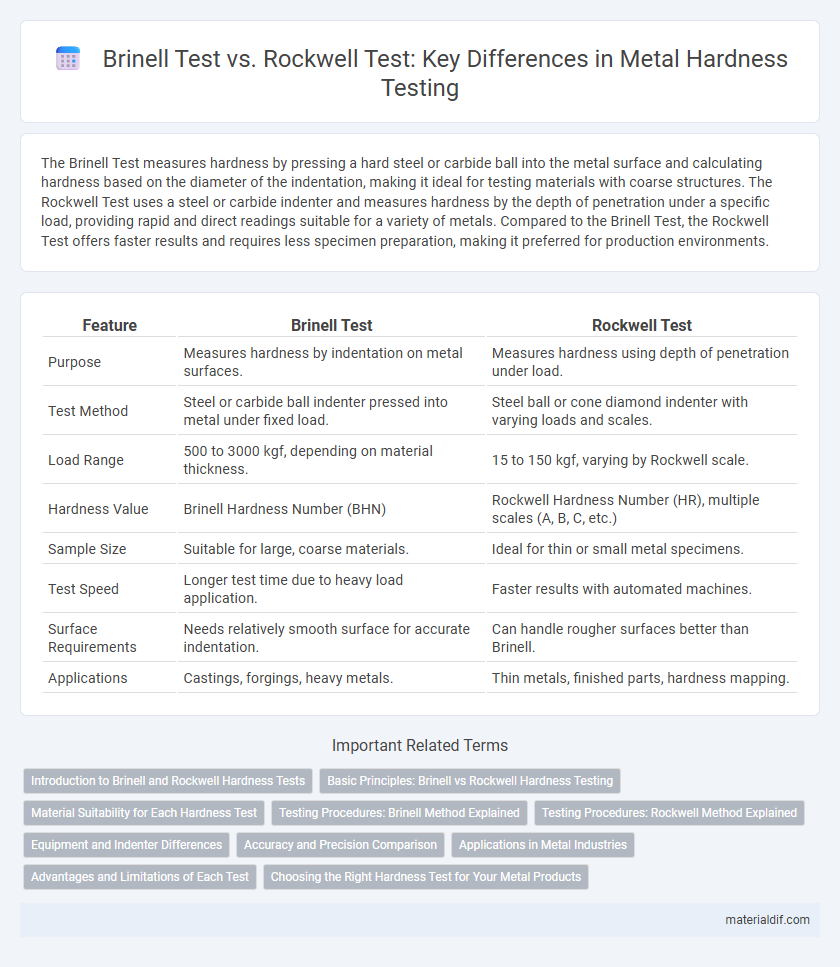

The Brinell Test measures hardness by pressing a hard steel or carbide ball into the metal surface and calculating hardness based on the diameter of the indentation, making it ideal for testing materials with coarse structures. The Rockwell Test uses a steel or carbide indenter and measures hardness by the depth of penetration under a specific load, providing rapid and direct readings suitable for a variety of metals. Compared to the Brinell Test, the Rockwell Test offers faster results and requires less specimen preparation, making it preferred for production environments.

Table of Comparison

| Feature | Brinell Test | Rockwell Test |

|---|---|---|

| Purpose | Measures hardness by indentation on metal surfaces. | Measures hardness using depth of penetration under load. |

| Test Method | Steel or carbide ball indenter pressed into metal under fixed load. | Steel ball or cone diamond indenter with varying loads and scales. |

| Load Range | 500 to 3000 kgf, depending on material thickness. | 15 to 150 kgf, varying by Rockwell scale. |

| Hardness Value | Brinell Hardness Number (BHN) | Rockwell Hardness Number (HR), multiple scales (A, B, C, etc.) |

| Sample Size | Suitable for large, coarse materials. | Ideal for thin or small metal specimens. |

| Test Speed | Longer test time due to heavy load application. | Faster results with automated machines. |

| Surface Requirements | Needs relatively smooth surface for accurate indentation. | Can handle rougher surfaces better than Brinell. |

| Applications | Castings, forgings, heavy metals. | Thin metals, finished parts, hardness mapping. |

Introduction to Brinell and Rockwell Hardness Tests

Brinell and Rockwell hardness tests are essential methods for measuring the hardness of metals and alloys by assessing their resistance to deformation. The Brinell test uses a hard steel or carbide ball to indent the material under a predetermined load, evaluating hardness based on the diameter of the indentation. The Rockwell test measures hardness by determining the depth of penetration of an indenter under a fixed load, offering faster and more direct readings suitable for various metal types.

Basic Principles: Brinell vs Rockwell Hardness Testing

Brinell hardness testing measures material hardness by pressing a hardened steel or carbide ball into the metal surface under a specified load, evaluating the diameter of the indentation to calculate hardness. Rockwell hardness testing uses a steel or tungsten carbide indenter that penetrates the metal surface under minor and major loads, with hardness determined by the depth of the indentation on a specific Rockwell scale. Brinell is preferred for materials with coarse grains and castings, while Rockwell is faster and more suitable for finished products and materials with smoother surfaces.

Material Suitability for Each Hardness Test

The Brinell test suits materials with coarse structures or uneven surfaces like castings and forgings, offering reliable hardness values by using a large indenter and low pressure. The Rockwell test fits smooth, finished metals such as steel and aluminum, providing faster readings with multiple scales for differing hardness levels. Material composition and surface texture critically influence the choice between Brinell and Rockwell hardness testing to ensure accurate hardness measurement.

Testing Procedures: Brinell Method Explained

The Brinell hardness test measures metal hardness by pressing a hardened steel or carbide ball into the material's surface under a specified load, typically ranging from 500 to 3000 kgf, for 10 to 30 seconds. The diameter of the indentation left on the metal is measured using a microscope, and the Brinell Hardness Number (BHN) is calculated by dividing the applied load by the surface area of the indentation. This method is especially effective for testing materials with coarse structures or uneven surfaces, providing reliable hardness values for castings and forgings.

Testing Procedures: Rockwell Method Explained

The Rockwell test measures metal hardness by applying a minor load followed by a major load using a steel ball or diamond cone indenter, then directly reading the depth of penetration on a dial or digital display. This method offers rapid, non-destructive testing ideal for finished parts, contrasting with the Brinell test which uses a larger indenter and calculates hardness from the indentation diameter. Rockwell testing provides precise, repeatable results and adapts to various metal types by selecting appropriate scales such as HRC for hard steels or HRB for softer alloys.

Equipment and Indenter Differences

The Brinell test uses a large hardened steel or tungsten carbide ball indenter, typically 10mm in diameter, pressed into the metal surface using a fixed load ranging from 500 to 3000 kgf, requiring a microscope to measure the indentation diameter. The Rockwell test employs various small steel balls or diamond cone (brale) indenters, with load levels between 60 and 150 kgf, allowing direct digital or dial reading of hardness without microscope measurement. Brinell equipment is bulkier and designed for testing coarse materials with rough surfaces, while Rockwell machines are more compact and versatile for rapid hardness testing on smooth or finished metal surfaces.

Accuracy and Precision Comparison

The Brinell test is more suitable for testing materials with coarse structures due to its larger indenter, providing consistent and repeatable hardness values but slightly less precision on small or thin specimens. The Rockwell test offers higher precision with a smaller indenter and digital readout, allowing faster measurements and better accuracy on thin or hardened materials. Both tests yield reliable hardness values, but the Rockwell test is generally preferred for detailed material analysis requiring fine accuracy and precision.

Applications in Metal Industries

The Brinell Test is widely used in metal industries for evaluating the hardness of castings, forgings, and materials with coarse structures due to its ability to measure large surface areas. The Rockwell Test offers rapid, direct hardness readings ideal for quality control in production lines involving metals like steel and aluminum, where surface finishing and precise hardness values are critical. Both tests serve complementary roles in metal processing, with Brinell preferred for heavy materials and Rockwell favored for thin or finished components.

Advantages and Limitations of Each Test

The Brinell test offers a significant advantage in evaluating materials with coarse structures or heterogeneous surfaces, providing a clear hardness value by measuring the indentation diameter made by a steel or carbide ball under a fixed load. Its limitation lies in being less suitable for small or thin materials due to the larger indentation size and slower testing process compared to the Rockwell test, which is known for its rapid testing capability and direct digital hardness readings across various scales. However, the Rockwell test's limitation includes potential inaccuracies on rough or uneven surfaces and smaller sample sizes, which can affect the reliability of the hardness measurement.

Choosing the Right Hardness Test for Your Metal Products

Selecting the right hardness test for metal products depends on the material type and application requirements, with the Brinell test offering precise results for coarse materials due to its larger indentation size, while the Rockwell test provides quicker results suitable for harder metals with minimal surface damage. Brinell testing uses a steel or carbide ball indenter and is ideal for castings and forgings, whereas Rockwell testing employs a steel or diamond cone indenter and measures depth of penetration, making it preferable for thin or finished metals. Understanding factors such as test speed, sample surface, and hardness range ensures accurate assessment and optimal quality control in metal manufacturing.

Brinell Test vs Rockwell Test Infographic

materialdif.com

materialdif.com