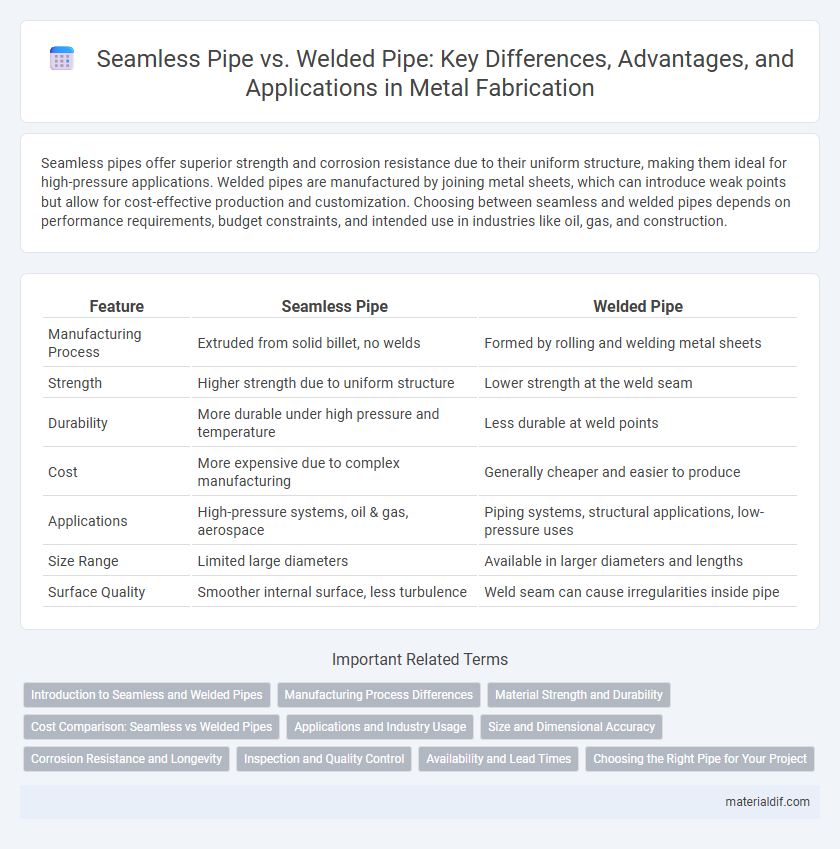

Seamless pipes offer superior strength and corrosion resistance due to their uniform structure, making them ideal for high-pressure applications. Welded pipes are manufactured by joining metal sheets, which can introduce weak points but allow for cost-effective production and customization. Choosing between seamless and welded pipes depends on performance requirements, budget constraints, and intended use in industries like oil, gas, and construction.

Table of Comparison

| Feature | Seamless Pipe | Welded Pipe |

|---|---|---|

| Manufacturing Process | Extruded from solid billet, no welds | Formed by rolling and welding metal sheets |

| Strength | Higher strength due to uniform structure | Lower strength at the weld seam |

| Durability | More durable under high pressure and temperature | Less durable at weld points |

| Cost | More expensive due to complex manufacturing | Generally cheaper and easier to produce |

| Applications | High-pressure systems, oil & gas, aerospace | Piping systems, structural applications, low-pressure uses |

| Size Range | Limited large diameters | Available in larger diameters and lengths |

| Surface Quality | Smoother internal surface, less turbulence | Weld seam can cause irregularities inside pipe |

Introduction to Seamless and Welded Pipes

Seamless pipes are manufactured through a process that involves extruding a solid billet to form a hollow tube, resulting in a pipe with no joints or welds, which enhances its strength and resistance to pressure. Welded pipes are produced by rolling metal plates or strips and then welding them along the seam, offering flexibility in size and thickness but potentially less uniform strength compared to seamless pipes. Both types serve critical roles in industries such as oil and gas, construction, and automotive, where material properties and cost efficiency drive the choice between seamless and welded pipes.

Manufacturing Process Differences

Seamless pipes are manufactured using a solid billet that is heated and then pierced to create a hollow tube without any joints or welds, ensuring uniform strength and resistance to pressure. Welded pipes are made by rolling metal sheets or plates and joining the edges through welding methods such as electric resistance welding (ERW) or submerged arc welding (SAW), resulting in a seam along the pipe length. The absence of seams in seamless pipes eliminates potential weak points, while welded pipes offer advantages in size customization and lower production costs.

Material Strength and Durability

Seamless pipes exhibit superior material strength and durability due to their uniform structure, which eliminates weak points commonly found in welded seams. The absence of welds enhances resistance to pressure, corrosion, and mechanical stress, making seamless pipes ideal for high-pressure and high-temperature applications. Welded pipes, while cost-effective and easier to produce, often display reduced strength at the weld joints, potentially compromising long-term durability under extreme conditions.

Cost Comparison: Seamless vs Welded Pipes

Seamless pipes typically incur higher manufacturing costs due to their complex extrusion process and superior strength properties, making them more expensive than welded pipes. Welded pipes offer a cost-effective alternative by using rolled and welded steel plates, which reduces production expenses and material waste. In applications where budget constraints are critical and moderate strength suffices, welded pipes deliver better cost efficiency without significant compromise on performance.

Applications and Industry Usage

Seamless pipes are preferred in high-pressure and high-temperature applications such as oil and gas exploration, power plants, and chemical processing due to their superior strength and corrosion resistance. Welded pipes find extensive use in low to medium-pressure applications like water transportation, infrastructure, and HVAC systems where cost-effectiveness and ease of fabrication are critical. Industries including automotive, construction, and shipbuilding rely on welded pipes for structural and non-critical fluid transport, while seamless pipes dominate aerospace, petrochemical, and nuclear sectors requiring durability and integrity.

Size and Dimensional Accuracy

Seamless pipes offer superior dimensional accuracy and consistent wall thickness due to their manufacturing process, which involves extrusion or rotary piercing without any welds. In contrast, welded pipes are created by rolling metal and welding the seam, which can introduce slight size variations and less uniformity. Seamless pipes are preferred for applications requiring precise dimensions and high-pressure tolerance, especially in larger diameters.

Corrosion Resistance and Longevity

Seamless pipes exhibit superior corrosion resistance due to their uniform structure, lacking weld seams that can act as weak points for corrosion initiation. Welded pipes often face increased susceptibility to corrosion at the welded joints, potentially reducing their service life in harsh environments. Consequently, seamless pipes typically offer enhanced longevity, especially in applications requiring resistance to chemical or environmental degradation.

Inspection and Quality Control

Seamless pipes undergo rigorous ultrasonic and eddy current testing to detect internal flaws, ensuring superior structural integrity and uniformity, while welded pipes require extensive radiographic and magnetic particle inspections to verify weld seam quality and detect surface or subsurface defects. The seamless manufacturing process inherently minimizes weld-related weaknesses, resulting in higher tensile strength and enhanced pressure resistance, whereas welded pipes necessitate meticulous quality control measures to prevent defects such as porosity and slag inclusions. Both pipe types adhere to stringent standards like ASTM A106 for seamless and ASTM A53 for welded pipes, with thorough dimensional checks and hydrostatic testing critical for certifying overall performance and safety.

Availability and Lead Times

Seamless pipes generally have longer lead times due to complex manufacturing processes involving extrusion and rotary piercing, which limit their availability compared to welded pipes. Welded pipes, produced by rolling and welding steel plates or strips, offer greater availability and faster delivery options because of streamlined production and widespread material sources. Industries requiring quick turnaround and cost-efficiency often favor welded pipes, while seamless pipes are selected for higher pressure applications despite limited stock and extended procurement periods.

Choosing the Right Pipe for Your Project

Seamless pipes offer superior strength and resistance to high pressure, making them ideal for critical applications such as oil and gas transportation or high-temperature environments. Welded pipes are more cost-effective and available in larger diameters, suitable for lower pressure applications and structural use where budget constraints are important. Selecting the right pipe depends on project requirements including pressure, temperature, budget, and corrosion resistance, ensuring optimal performance and longevity.

Seamless Pipe vs Welded Pipe Infographic

materialdif.com

materialdif.com