Welding and soldering are two distinct metal-joining techniques that differ primarily in temperature and bonding method. Welding involves melting the base metals to create a strong, fused joint ideal for structural applications, while soldering uses a lower melting point filler metal to bond surfaces without melting the base materials, making it suitable for delicate or electrical components. Selecting the appropriate process depends on the metals involved, required joint strength, and the specific demands of the project.

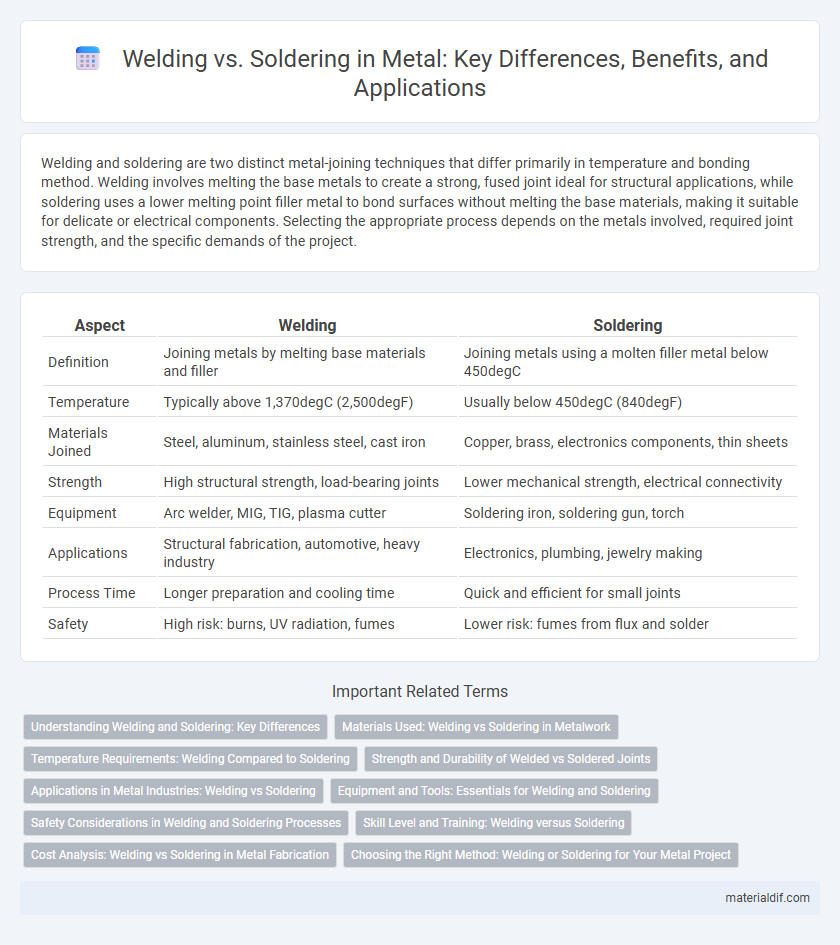

Table of Comparison

| Aspect | Welding | Soldering |

|---|---|---|

| Definition | Joining metals by melting base materials and filler | Joining metals using a molten filler metal below 450degC |

| Temperature | Typically above 1,370degC (2,500degF) | Usually below 450degC (840degF) |

| Materials Joined | Steel, aluminum, stainless steel, cast iron | Copper, brass, electronics components, thin sheets |

| Strength | High structural strength, load-bearing joints | Lower mechanical strength, electrical connectivity |

| Equipment | Arc welder, MIG, TIG, plasma cutter | Soldering iron, soldering gun, torch |

| Applications | Structural fabrication, automotive, heavy industry | Electronics, plumbing, jewelry making |

| Process Time | Longer preparation and cooling time | Quick and efficient for small joints |

| Safety | High risk: burns, UV radiation, fumes | Lower risk: fumes from flux and solder |

Understanding Welding and Soldering: Key Differences

Welding involves melting base metals to create a strong, permanent joint, while soldering uses a filler metal with a lower melting point to bond metals without melting the base materials. Welding typically requires higher temperatures and produces joints with superior mechanical strength, ideal for structural applications. Soldering is preferred for delicate or electronic components where precise, low-heat connections are essential.

Materials Used: Welding vs Soldering in Metalwork

Welding in metalwork typically involves the use of filler metals with high melting points like steel, aluminum, or stainless steel, which fuse base metals through intense heat. Soldering uses low-melting-point alloys, such as tin-lead or lead-free solder, to join metals by melting the filler without melting the base materials. The choice of materials depends on factors like thermal conductivity, melting temperature, and the mechanical strength required for the joint.

Temperature Requirements: Welding Compared to Soldering

Welding requires significantly higher temperatures, often exceeding 1,500degC, to melt base metals and create a strong joint through fusion, whereas soldering operates at much lower temperatures, typically between 180degC and 250degC, using a filler metal with a lower melting point. The intense heat in welding allows for robust structural connections in metals like steel and aluminum, while soldering's moderate heat preserves delicate components in electronics and plumbing. The difference in temperature requirements defines their applications, with welding suited for heavy-duty fabrication and soldering ideal for precision work.

Strength and Durability of Welded vs Soldered Joints

Welded joints provide superior strength and durability compared to soldered joints due to the fusion of base metals creating a continuous metal structure. Soldered joints rely on a filler material with a lower melting point, resulting in weaker bonds that are more susceptible to mechanical stress and environmental factors. For critical applications requiring high load resistance and long-term reliability, welding is the preferred method over soldering.

Applications in Metal Industries: Welding vs Soldering

Welding is commonly used in heavy metal industries such as automotive, construction, and shipbuilding due to its ability to create strong, permanent joints in thick metal materials like steel and aluminum. Soldering is preferred in electronics and delicate metal work where lower temperatures prevent damage to components, enabling precise joining of fine wires and thin metal parts. The choice between welding and soldering depends on the metal type, joint strength requirements, and heat sensitivity of the materials involved.

Equipment and Tools: Essentials for Welding and Soldering

Welding requires specialized equipment such as welding machines (MIG, TIG, or arc welders), protective gear including helmets with auto-darkening filters, welding gloves, and clamps to secure metal pieces. Soldering uses simpler tools like soldering irons or guns, solder wire made of alloys like tin and lead or lead-free variants, and flux to improve metal adhesion. Proper ventilation and heat-resistant work surfaces are essential for both processes to ensure safety and effective bonding.

Safety Considerations in Welding and Soldering Processes

Welding involves high temperatures, intense light, and molten metal, necessitating protective gear such as helmets with filtered lenses, flame-resistant clothing, and proper ventilation to prevent burns, eye damage, and inhalation of harmful fumes. Soldering, while generally lower risk, still requires adequate ventilation and eye protection to avoid exposure to lead or flux fumes and accidental burns from hot soldering irons. Both processes demand stringent safety protocols to minimize the risk of fire, toxic exposure, and physical injury in metalworking environments.

Skill Level and Training: Welding versus Soldering

Welding demands higher skill levels and extensive training due to its complexity, involving heat-intensive processes that require precise control and safety knowledge. Soldering is generally easier to learn, with shorter training periods, as it uses lower temperatures and simpler techniques suitable for delicate or small-scale metalwork. Professionals in welding often undergo formal certification, while soldering skills can be acquired through basic courses or on-the-job practice.

Cost Analysis: Welding vs Soldering in Metal Fabrication

Welding typically incurs higher upfront costs due to expensive equipment and skilled labor requirements but offers stronger, more durable joints ideal for heavy-duty metal fabrication. Soldering involves lower material and labor expenses, making it cost-effective for lighter applications and delicate metals, though it may lack the structural strength of welded joints. Evaluating total expenditure requires considering project scale, metal type, and long-term durability needs to determine the most economical method.

Choosing the Right Method: Welding or Soldering for Your Metal Project

Welding joins metals by melting their surfaces to create a strong, permanent bond suited for structural projects requiring high strength and durability. Soldering uses a lower temperature filler metal to bond components without melting the base metals, ideal for delicate assemblies or electrical work. Selecting between welding and soldering depends on metal type, project strength requirements, and heat sensitivity.

Welding vs Soldering Infographic

materialdif.com

materialdif.com