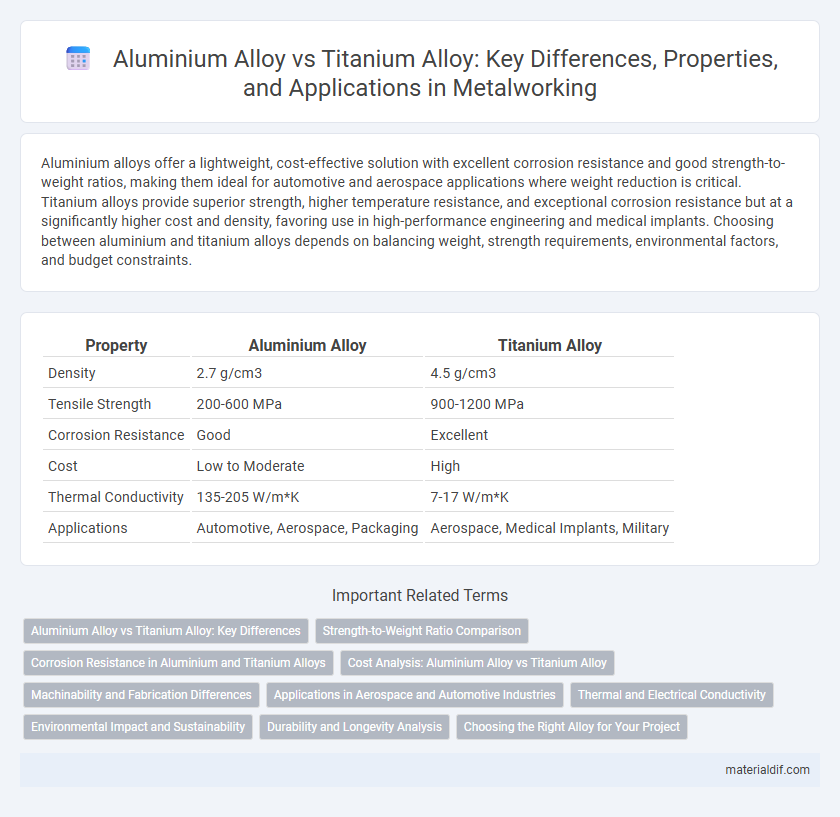

Aluminium alloys offer a lightweight, cost-effective solution with excellent corrosion resistance and good strength-to-weight ratios, making them ideal for automotive and aerospace applications where weight reduction is critical. Titanium alloys provide superior strength, higher temperature resistance, and exceptional corrosion resistance but at a significantly higher cost and density, favoring use in high-performance engineering and medical implants. Choosing between aluminium and titanium alloys depends on balancing weight, strength requirements, environmental factors, and budget constraints.

Table of Comparison

| Property | Aluminium Alloy | Titanium Alloy |

|---|---|---|

| Density | 2.7 g/cm3 | 4.5 g/cm3 |

| Tensile Strength | 200-600 MPa | 900-1200 MPa |

| Corrosion Resistance | Good | Excellent |

| Cost | Low to Moderate | High |

| Thermal Conductivity | 135-205 W/m*K | 7-17 W/m*K |

| Applications | Automotive, Aerospace, Packaging | Aerospace, Medical Implants, Military |

Aluminium Alloy vs Titanium Alloy: Key Differences

Aluminium alloy features a lower density of around 2.7 g/cm3 compared to titanium alloy's approximate 4.5 g/cm3, making it lighter and advantageous for weight-sensitive applications. Aluminium alloys offer excellent corrosion resistance and are generally more cost-effective than titanium alloys, which provide superior strength-to-weight ratios and exceptional high-temperature performance. The choice between aluminium and titanium alloys depends on balancing factors such as mechanical strength, weight, corrosion resistance, cost, and specific application requirements in industries like aerospace and automotive engineering.

Strength-to-Weight Ratio Comparison

Aluminium alloys exhibit a high strength-to-weight ratio, making them ideal for applications requiring lightweight components with moderate strength. Titanium alloys surpass aluminium in strength-to-weight ratio due to their superior tensile strength and lower density, offering enhanced performance in aerospace and high-stress environments. The critical comparison highlights titanium alloys' ability to deliver greater structural integrity while maintaining minimal weight, beneficial for advanced engineering designs.

Corrosion Resistance in Aluminium and Titanium Alloys

Titanium alloys exhibit superior corrosion resistance compared to aluminium alloys due to their stable oxide film formation, which effectively protects against oxidation and chemical attack in harsh environments. Aluminium alloys rely on a thin, self-healing alumina layer that offers decent corrosion protection but can degrade in chloride-rich or acidic conditions. In marine and chemical applications, titanium alloys are preferred for their exceptional durability and resistance to pitting and crevice corrosion.

Cost Analysis: Aluminium Alloy vs Titanium Alloy

Aluminium alloy offers a more cost-effective solution compared to titanium alloy, with raw material and manufacturing expenses significantly lower by up to 60-70%. Titanium alloys provide superior strength-to-weight ratio and corrosion resistance but come at a premium price, often costing 3 to 5 times more per kilogram than aluminium alloys. Budget-sensitive applications prioritize aluminium alloys due to their affordability and adequate performance, while titanium alloys dominate in aerospace and medical fields where high performance justifies the increased cost.

Machinability and Fabrication Differences

Aluminium alloys offer superior machinability due to their lower hardness and density, resulting in faster cutting speeds and reduced tool wear compared to titanium alloys. Titanium alloys require specialized tooling and slower machining processes because of their high strength, toughness, and tendency to work-harden, making fabrication more challenging and costly. The fabrication differences highlight aluminium alloys as ideal for mass production, while titanium alloys excel in high-performance applications demanding corrosion resistance and strength-to-weight ratio.

Applications in Aerospace and Automotive Industries

Aluminium alloys are extensively used in aerospace and automotive industries due to their lightweight nature and excellent corrosion resistance, improving fuel efficiency and vehicle performance. Titanium alloys, although more expensive, offer superior strength-to-weight ratio and high-temperature resistance, making them ideal for critical aerospace components and high-performance automotive parts. Both materials contribute to advancements in structural integrity and durability while meeting industry-specific weight reduction goals.

Thermal and Electrical Conductivity

Aluminium alloys exhibit high thermal conductivity ranging from 120 to 220 W/m*K, enabling efficient heat dissipation in applications like heat exchangers and electronics cooling. Titanium alloys, with thermal conductivity around 6 to 22 W/m*K, offer superior strength-to-weight ratio but limited heat transfer capabilities. Electrically, aluminium alloys have conductivity approximately 35.5 MS/m, making them suitable for wiring and electrical components, whereas titanium alloys have much lower electrical conductivity about 1.8 MS/m, restricting their use in electrical applications.

Environmental Impact and Sustainability

Aluminium alloys exhibit a lower environmental impact in production due to their higher recyclability and lower energy consumption compared to titanium alloys, which require energy-intensive extraction and processing. Titanium alloys, while offering superior strength-to-weight ratios and corrosion resistance, have a more significant carbon footprint and limited recycling infrastructure. Sustainable metal selection often favors aluminium alloys for applications prioritizing environmental efficiency without compromising moderate performance requirements.

Durability and Longevity Analysis

Aluminium alloys exhibit moderate durability with excellent corrosion resistance, making them suitable for applications requiring lightweight and longevity in non-extreme environments. Titanium alloys surpass aluminium in durability due to their superior strength-to-weight ratio and exceptional resistance to fatigue, corrosion, and high temperatures, enhancing longevity in aerospace and medical implants. The longevity of titanium alloys far exceeds aluminium alloys in demanding conditions, providing sustained performance and reduced maintenance costs over time.

Choosing the Right Alloy for Your Project

Aluminium alloy offers lightweight properties, excellent corrosion resistance, and cost-effectiveness, making it ideal for automotive and aerospace applications where weight reduction is critical. Titanium alloy excels in high-strength, temperature resistance, and biocompatibility, suited for medical implants, aerospace, and high-performance engineering projects. Selecting the right alloy depends on balancing factors such as mechanical strength, environmental conditions, budget constraints, and specific project requirements.

Aluminium Alloy vs Titanium Alloy Infographic

materialdif.com

materialdif.com