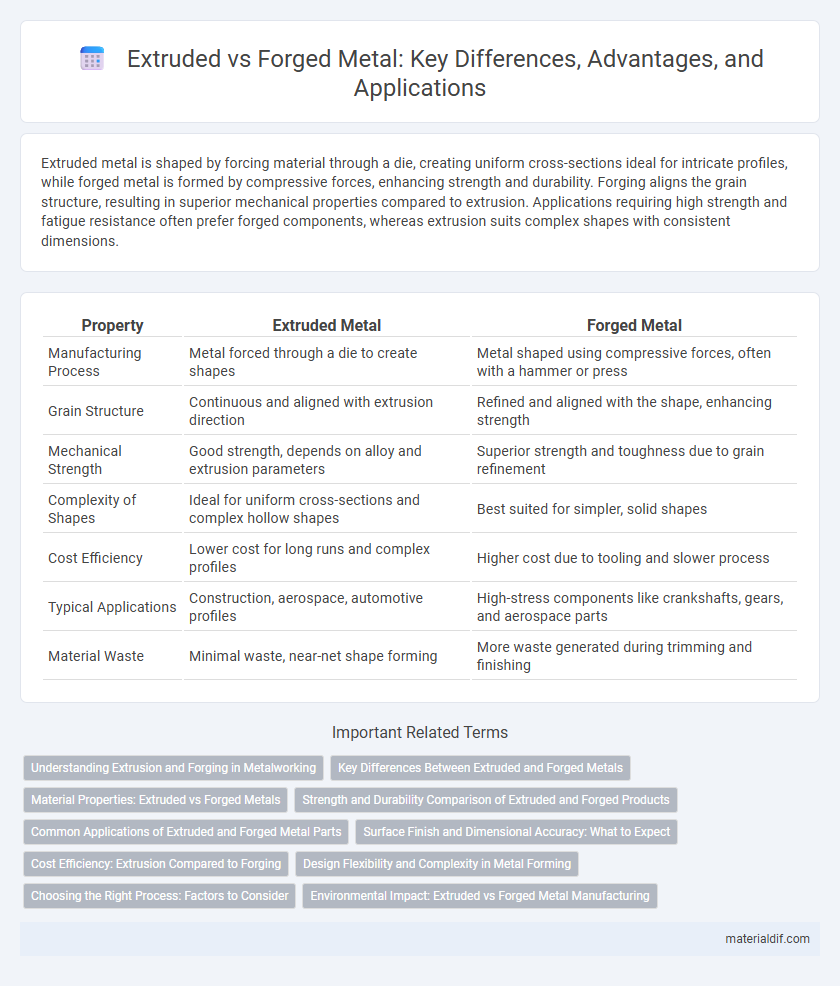

Extruded metal is shaped by forcing material through a die, creating uniform cross-sections ideal for intricate profiles, while forged metal is formed by compressive forces, enhancing strength and durability. Forging aligns the grain structure, resulting in superior mechanical properties compared to extrusion. Applications requiring high strength and fatigue resistance often prefer forged components, whereas extrusion suits complex shapes with consistent dimensions.

Table of Comparison

| Property | Extruded Metal | Forged Metal |

|---|---|---|

| Manufacturing Process | Metal forced through a die to create shapes | Metal shaped using compressive forces, often with a hammer or press |

| Grain Structure | Continuous and aligned with extrusion direction | Refined and aligned with the shape, enhancing strength |

| Mechanical Strength | Good strength, depends on alloy and extrusion parameters | Superior strength and toughness due to grain refinement |

| Complexity of Shapes | Ideal for uniform cross-sections and complex hollow shapes | Best suited for simpler, solid shapes |

| Cost Efficiency | Lower cost for long runs and complex profiles | Higher cost due to tooling and slower process |

| Typical Applications | Construction, aerospace, automotive profiles | High-stress components like crankshafts, gears, and aerospace parts |

| Material Waste | Minimal waste, near-net shape forming | More waste generated during trimming and finishing |

Understanding Extrusion and Forging in Metalworking

Extrusion involves forcing heated metal through a shaped die to create continuous profiles with uniform cross-sections, ideal for complex shapes and consistent dimensions. Forging reshapes metal through compressive forces, often using hammers or presses, to enhance strength by refining grain structure, making it suitable for high-stress components. Understanding these processes is critical for selecting the right method based on mechanical properties, design complexity, and production volume in metalworking.

Key Differences Between Extruded and Forged Metals

Extruded metals are produced by forcing material through a shaped die, resulting in consistent cross-sectional profiles ideal for complex shapes and lightweight applications. Forged metals undergo compressive forces in molds, enhancing grain structure for superior strength, toughness, and durability compared to extruded parts. Key differences include the mechanical properties, surface finish, and structural integrity, with forging typically offering higher strength and extrusion providing design flexibility.

Material Properties: Extruded vs Forged Metals

Extruded metals exhibit uniform grain flow and precise dimensional control, resulting in enhanced tensile strength and improved surface finish. Forged metals possess superior mechanical properties due to the controlled deformation process, which refines the grain structure and increases toughness, fatigue resistance, and impact strength. Both methods enhance material properties, but forging typically delivers higher strength and durability for critical structural applications.

Strength and Durability Comparison of Extruded and Forged Products

Forged metal products exhibit superior strength and durability due to their grain structure alignment and reduced porosity, making them ideal for high-stress applications. Extruded metals offer consistent cross-sectional profiles with good mechanical properties but generally fall short in impact resistance compared to forged counterparts. Choosing between extruded and forged components depends on specific performance requirements, with forging favored for critical load-bearing parts.

Common Applications of Extruded and Forged Metal Parts

Extruded metal parts are commonly used in construction, automotive frames, and aerospace components due to their uniform cross-sections and lightweight properties. Forged metal parts find applications in heavy machinery, automotive crankshafts, and aerospace landing gear because of their superior strength and fatigue resistance. Both processes optimize material properties for specific industrial requirements, enhancing durability and performance.

Surface Finish and Dimensional Accuracy: What to Expect

Extruded metal typically offers a smoother surface finish with consistent dimensional accuracy due to the controlled pressure applied during the extrusion process. Forged metal, while often stronger and more durable, can exhibit a rougher surface with slight variations in dimensions caused by the impact forces involved. Choosing between extruded and forged metal depends on the specific application requirements for surface finish quality and tight tolerance in dimensions.

Cost Efficiency: Extrusion Compared to Forging

Extrusion offers superior cost efficiency compared to forging due to lower tooling expenses and faster production rates, especially for complex cross-sectional profiles. Forging demands higher energy consumption and skilled labor, resulting in increased operational costs for high-volume manufacturing. Extruded aluminum, in particular, provides a balance of strength and cost-effectiveness ideal for structural and lightweight components.

Design Flexibility and Complexity in Metal Forming

Extruded metal offers superior design flexibility, enabling the creation of complex cross-sectional profiles with consistent wall thickness and intricate shapes. Forged metal, while limited in geometric complexity, provides enhanced mechanical properties and structural integrity due to its grain flow alignment. Engineers often choose extrusion for detailed, lightweight designs, whereas forging suits applications demanding high strength and durability in simpler geometries.

Choosing the Right Process: Factors to Consider

Selecting between extruded and forged metal processes depends on factors such as desired mechanical properties, complexity of shape, and production volume. Forging provides superior strength and fatigue resistance ideal for high-stress applications, while extrusion excels in creating complex cross-sectional profiles efficiently. Cost-effectiveness and lead time also influence the decision, with extrusion offering faster turnaround and forging typically requiring longer processing but yielding enhanced structural integrity.

Environmental Impact: Extruded vs Forged Metal Manufacturing

Extruded metal manufacturing typically consumes less energy than forged metal processes due to lower temperature requirements and continuous shaping methods. Forged metals often involve higher energy use and carbon emissions because of the intense heat and pressure applied to shape the material. Lifecycle assessments show extruded metals generally have a smaller environmental footprint, contributing to reduced greenhouse gas emissions and material waste.

Extruded vs Forged Infographic

materialdif.com

materialdif.com