Corrosion involves the gradual destruction of metals due to chemical reactions with environmental elements, often resulting in rust or other surface degradation. Oxidation is a specific type of corrosion where metal reacts with oxygen, forming an oxide layer that can either protect the metal or lead to further deterioration. Understanding the distinction between corrosion and oxidation is crucial for selecting appropriate metals and protective treatments in industrial applications.

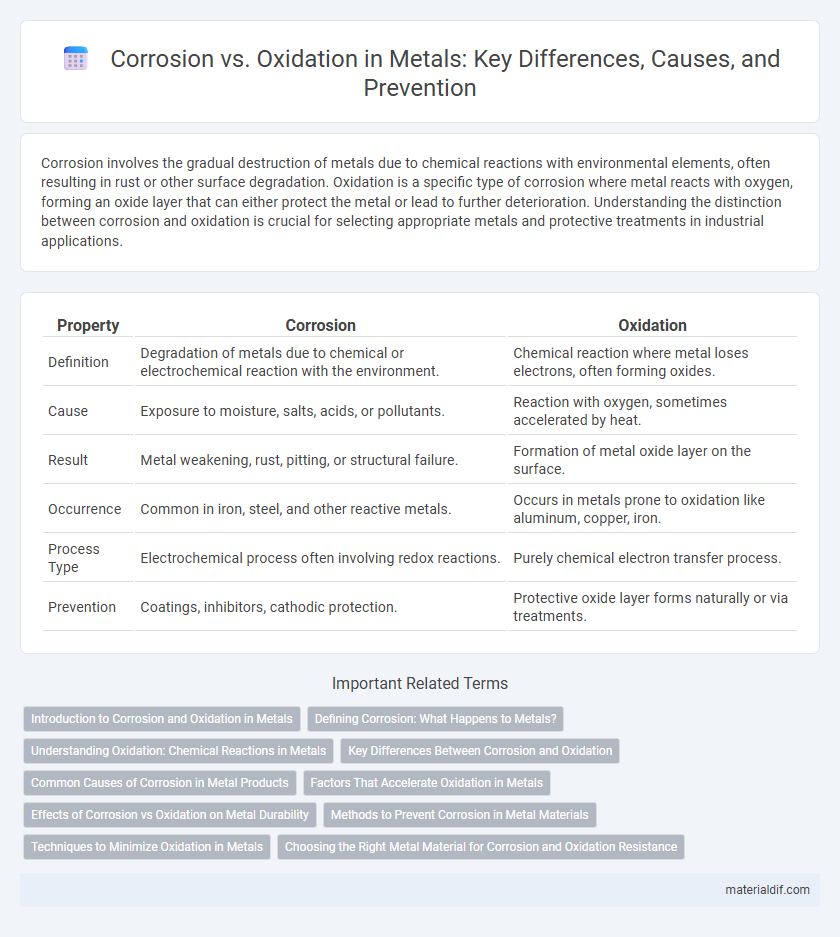

Table of Comparison

| Property | Corrosion | Oxidation |

|---|---|---|

| Definition | Degradation of metals due to chemical or electrochemical reaction with the environment. | Chemical reaction where metal loses electrons, often forming oxides. |

| Cause | Exposure to moisture, salts, acids, or pollutants. | Reaction with oxygen, sometimes accelerated by heat. |

| Result | Metal weakening, rust, pitting, or structural failure. | Formation of metal oxide layer on the surface. |

| Occurrence | Common in iron, steel, and other reactive metals. | Occurs in metals prone to oxidation like aluminum, copper, iron. |

| Process Type | Electrochemical process often involving redox reactions. | Purely chemical electron transfer process. |

| Prevention | Coatings, inhibitors, cathodic protection. | Protective oxide layer forms naturally or via treatments. |

Introduction to Corrosion and Oxidation in Metals

Corrosion in metals refers to the electrochemical process where metals deteriorate due to reactions with their environment, often resulting in rust or other forms of material degradation. Oxidation, a specific type of corrosion, involves the transfer of electrons from metal atoms to oxygen molecules, forming metal oxides on the surface. Both processes compromise metal integrity but vary in mechanisms and environmental influences, crucial for understanding metal durability and protection measures.

Defining Corrosion: What Happens to Metals?

Corrosion is the electrochemical process where metals deteriorate due to reactions with their environment, often involving moisture, oxygen, and salts. This degradation leads to the formation of oxides or other compounds, weakening the metal's structural integrity. Unlike simple oxidation, corrosion typically results in material loss and compromised mechanical properties.

Understanding Oxidation: Chemical Reactions in Metals

Oxidation in metals involves the chemical reaction between metal atoms and oxygen molecules, resulting in the formation of metal oxides that alter the metal's surface properties. This process typically involves the transfer of electrons from the metal to oxygen, changing the metal's oxidation state and leading to structural and color changes. Unlike corrosion, which can cause material degradation and loss of integrity, oxidation is a broader chemical phenomenon that may form protective oxide layers preventing further damage.

Key Differences Between Corrosion and Oxidation

Corrosion is a chemical or electrochemical reaction between a metal and its environment that leads to the deterioration of the metal's properties, often forming rust or other compounds. Oxidation specifically refers to the chemical reaction where metal atoms lose electrons, typically forming an oxide layer on the surface without necessarily damaging the structural integrity. The key difference lies in corrosion being a destructive process resulting in material degradation, while oxidation can be a protective or benign surface change depending on the metal and conditions.

Common Causes of Corrosion in Metal Products

Common causes of corrosion in metal products include exposure to moisture, oxygen, and various chemicals such as acids, salts, and industrial pollutants. Electrochemical reactions between metal surfaces and electrolytes, often found in humid or saline environments, accelerate the degradation process. Mechanical stress and microstructural defects also contribute to corrosion by creating sites for pitting and localized attack.

Factors That Accelerate Oxidation in Metals

High humidity and elevated temperatures significantly accelerate oxidation in metals by increasing the rate of electrochemical reactions on the metal surface. The presence of electrolytes, such as salts in marine environments, enhances metal ion mobility and promotes the formation of rust or other oxides. Mechanical stress and surface impurities further catalyze oxidation by creating localized sites for electron transfer and chemical attack.

Effects of Corrosion vs Oxidation on Metal Durability

Corrosion significantly reduces metal durability by causing material loss and structural weakness through chemical reactions with environmental elements, especially in the presence of moisture and salts. Oxidation primarily forms a protective oxide layer on the metal surface, which can enhance durability by preventing further degradation, although uncontrolled oxidation can lead to surface brittleness. The severity of corrosion typically results in accelerated deterioration and compromised mechanical integrity, whereas controlled oxidation may extend the lifespan of metal components.

Methods to Prevent Corrosion in Metal Materials

Protective coatings like paint, enamel, and galvanization create a barrier that prevents moisture and oxygen from reaching metal surfaces, effectively reducing corrosion risk. Cathodic protection techniques, such as sacrificial anodes or impressed current systems, inhibit electrochemical reactions that cause metal degradation. Regular maintenance, including cleaning to remove contaminants and applying corrosion inhibitors, extends the lifespan of metal materials by minimizing oxidative damage.

Techniques to Minimize Oxidation in Metals

Techniques to minimize oxidation in metals include applying protective coatings such as paint, varnish, or galvanization to create a barrier against oxygen exposure. Controlled atmospheres with reduced oxygen levels during manufacturing processes help prevent oxidative reactions. Employing alloying elements like chromium or nickel enhances oxidation resistance by forming stable oxide layers that protect the metal surface.

Choosing the Right Metal Material for Corrosion and Oxidation Resistance

Selecting the appropriate metal material for resistance to corrosion and oxidation depends on the specific environment and application conditions. Stainless steel, aluminum, and titanium alloys offer excellent corrosion resistance due to their ability to form passive oxide layers that prevent further degradation. Understanding the metal's electrochemical properties and exposure factors ensures optimal durability and longevity in harsh or oxidative environments.

Corrosion vs Oxidation Infographic

materialdif.com

materialdif.com