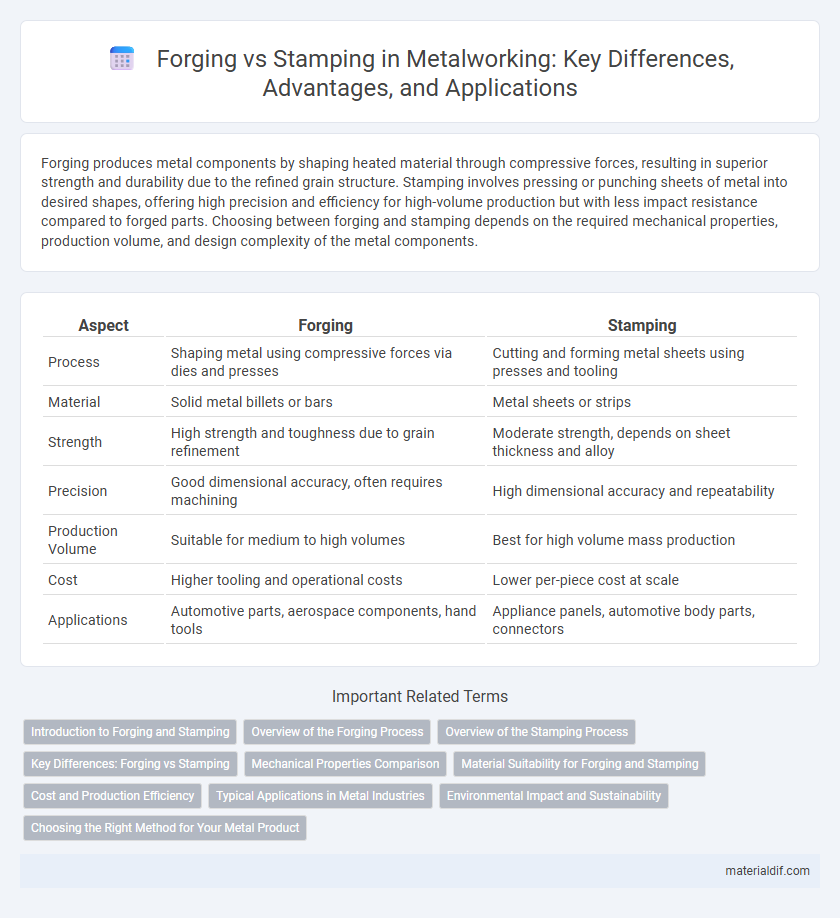

Forging produces metal components by shaping heated material through compressive forces, resulting in superior strength and durability due to the refined grain structure. Stamping involves pressing or punching sheets of metal into desired shapes, offering high precision and efficiency for high-volume production but with less impact resistance compared to forged parts. Choosing between forging and stamping depends on the required mechanical properties, production volume, and design complexity of the metal components.

Table of Comparison

| Aspect | Forging | Stamping |

|---|---|---|

| Process | Shaping metal using compressive forces via dies and presses | Cutting and forming metal sheets using presses and tooling |

| Material | Solid metal billets or bars | Metal sheets or strips |

| Strength | High strength and toughness due to grain refinement | Moderate strength, depends on sheet thickness and alloy |

| Precision | Good dimensional accuracy, often requires machining | High dimensional accuracy and repeatability |

| Production Volume | Suitable for medium to high volumes | Best for high volume mass production |

| Cost | Higher tooling and operational costs | Lower per-piece cost at scale |

| Applications | Automotive parts, aerospace components, hand tools | Appliance panels, automotive body parts, connectors |

Introduction to Forging and Stamping

Forging shapes metal by applying localized compressive forces, typically using a hammer or press, which refines the grain structure and enhances mechanical properties. Stamping involves cutting or shaping metal sheets through a die, enabling high-volume production with precise dimensions and consistent repeatability. Both processes are fundamental in manufacturing, with forging preferred for strength-critical components and stamping favored for complex, lightweight parts.

Overview of the Forging Process

Forging is a manufacturing process that shapes metal using localized compressive forces, typically delivered by a hammer or press. This process enhances the metal's structural integrity by refining its grain structure and improving mechanical properties like strength and toughness. Forging is commonly used for producing high-strength components in automotive, aerospace, and industrial applications.

Overview of the Stamping Process

The stamping process involves shaping metal sheets into specific forms using a die and a press in a rapid, high-volume production setting. This method excels in producing consistent, intricate designs with minimal material waste, ideal for automotive, appliance, and electronic components. Stamping offers precise dimensional control and repeatability, making it a cost-effective choice for mass manufacturing of metal parts.

Key Differences: Forging vs Stamping

Forging shapes metal by applying compressive forces, producing parts with superior strength and structural integrity due to grain flow alignment; stamping, however, involves cutting and shaping sheets using dies, ideal for high-volume, precise, and cost-effective production of thinner components. Forged parts typically exhibit enhanced mechanical properties, including toughness and fatigue resistance, whereas stamped parts prioritize intricate detail and dimensional accuracy. Choosing between forging and stamping depends on the required application strength, complexity, and production scale in metal manufacturing.

Mechanical Properties Comparison

Forging produces metals with superior mechanical properties, including enhanced tensile strength, impact resistance, and fatigue durability due to the controlled deformation and grain flow alignment. Stamping often results in components with less uniform microstructures, leading to reduced strength and increased susceptibility to cracking under stress. Forged parts exhibit better structural integrity, making them ideal for high-stress applications compared to stamped counterparts.

Material Suitability for Forging and Stamping

Forging is ideal for high-strength materials such as carbon steel, alloy steel, and titanium, where the metal's grain structure is refined for enhanced durability and toughness. Stamping suits thinner, softer metals like aluminum, brass, and thin-gauge steel, enabling high-speed production with precise shapes but less impact on grain structure. Selecting the appropriate process depends heavily on the material's ductility, thickness, and required mechanical properties.

Cost and Production Efficiency

Forging generally incurs higher initial tooling costs but offers superior material strength and durability, making it cost-effective for large-scale production runs where product reliability is crucial. Stamping provides lower per-unit costs and faster cycle times, ideal for high-volume manufacturing with simpler geometries. Choosing between forging and stamping depends on balancing upfront investment against long-term production efficiency and part performance requirements.

Typical Applications in Metal Industries

Forging is widely used in heavy industries for manufacturing high-strength components such as automotive crankshafts, aerospace landing gear, and industrial gears due to its ability to enhance metal grain structure and mechanical properties. Stamping is preferred in mass production of thin metal parts like automotive body panels, household appliance housings, and electronic enclosures because of its speed, precision, and cost-effectiveness. Both processes serve crucial roles in metal industries by balancing strength requirements and production efficiency depending on the application demands.

Environmental Impact and Sustainability

Forging produces metal components through deformation under high pressure, resulting in less material waste compared to stamping, which cuts and shapes metal sheets, often generating more scrap. The energy consumption in forging can be lower due to fewer processing steps, while stamping typically requires significant energy input for press operation and die production. Sustainable metal manufacturing benefits from forging's efficiency in material usage and longer-lasting parts, reducing the environmental footprint associated with raw material extraction and waste management.

Choosing the Right Method for Your Metal Product

Forging produces stronger, more durable metal parts by shaping heated metal under high pressure, ideal for components subjected to heavy stress such as automotive gears and aerospace fittings. Stamping offers precision and efficiency for high-volume production of thin metal sheets, commonly used in electronic housings and appliance panels. Selecting between forging and stamping depends on factors like material strength requirements, production volume, and component complexity.

Forging vs Stamping Infographic

materialdif.com

materialdif.com