Mill finish refers to the raw surface texture of metal after it is rolled or extruded, characterized by a dull, matte appearance with visible imperfections and mill marks. Mirror finish, on the other hand, involves extensive polishing to create a smooth, highly reflective surface that enhances corrosion resistance and aesthetic appeal. Choosing between mill finish and mirror finish depends on the intended application, balancing cost, durability, and visual requirements.

Table of Comparison

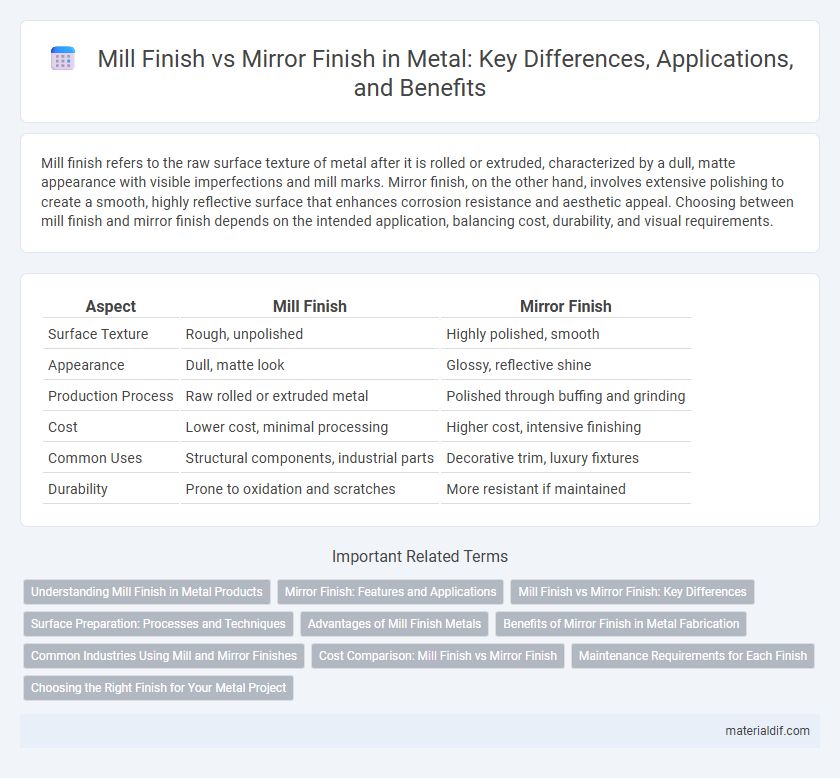

| Aspect | Mill Finish | Mirror Finish |

|---|---|---|

| Surface Texture | Rough, unpolished | Highly polished, smooth |

| Appearance | Dull, matte look | Glossy, reflective shine |

| Production Process | Raw rolled or extruded metal | Polished through buffing and grinding |

| Cost | Lower cost, minimal processing | Higher cost, intensive finishing |

| Common Uses | Structural components, industrial parts | Decorative trim, luxury fixtures |

| Durability | Prone to oxidation and scratches | More resistant if maintained |

Understanding Mill Finish in Metal Products

Mill finish in metal products refers to the surface texture left on metal after the initial manufacturing process, typically rolling or extrusion. This finish is characterized by a dull, rough appearance with visible marks from the production equipment, lacking any additional polishing or treatments. Understanding mill finish is crucial for applications where surface aesthetics are less important, prioritizing cost-efficiency and preparing the metal for subsequent finishing processes like painting or coating.

Mirror Finish: Features and Applications

Mirror finish metal surfaces exhibit a highly reflective, smooth appearance achieved through advanced polishing techniques that remove imperfections and enhance brightness. This finish is commonly used in decorative architectural elements, luxury automotive parts, and high-end consumer electronics where aesthetics and corrosion resistance are critical. Its ability to reduce surface roughness also improves cleanability and hygiene, making it ideal for medical devices and kitchen appliances.

Mill Finish vs Mirror Finish: Key Differences

Mill finish metal features a rough, unpolished surface straight from the rolling or extrusion process, often characterized by a dull gray appearance and occasional surface imperfections. Mirror finish metal undergoes extensive polishing and buffing to achieve a highly reflective, smooth surface with enhanced aesthetic appeal and corrosion resistance. The key differences lie in surface texture, reflectivity, and typical applications, where mill finish suits industrial uses and mirror finish is favored for decorative and precision components.

Surface Preparation: Processes and Techniques

Mill finish metal surfaces are produced directly from the rolling mill, characterized by a rough texture and visible imperfections like scale and scratches, requiring minimal cleaning before further processing. Mirror finish involves extensive surface preparation including polishing, buffing, and sometimes chemical treatments to achieve a smooth and highly reflective appearance free of defects. Techniques such as abrasive blasting, grinding, and electro-polishing are commonly employed to enhance surface smoothness and luster in mirror finishes, ensuring superior aesthetic and protective qualities.

Advantages of Mill Finish Metals

Mill finish metals offer cost-effective solutions with their natural, unpolished surface, eliminating the need for additional processing. Their rougher texture enhances paint adhesion and provides improved grip in industrial applications. The oxide layer formed during manufacturing also increases corrosion resistance compared to polished finishes.

Benefits of Mirror Finish in Metal Fabrication

Mirror finish in metal fabrication provides superior corrosion resistance by creating a smoother surface that minimizes exposure to environmental contaminants. This high-reflectivity finish enhances aesthetic appeal, making metal products visually striking and suitable for decorative applications. Additionally, the polished surface reduces friction, improving wear resistance and extending the lifespan of metal components in industrial use.

Common Industries Using Mill and Mirror Finishes

Mill finish is commonly used in construction, automotive, and manufacturing industries due to its cost-effectiveness and straightforward production process. Mirror finish is preferred in medical, aerospace, and food processing industries where surface smoothness and aesthetic appeal are critical for hygiene, corrosion resistance, and precision. The choice between mill and mirror finishes depends on industry-specific requirements for functionality, appearance, and durability.

Cost Comparison: Mill Finish vs Mirror Finish

Mill finish metal typically costs less due to minimal processing, as it is left in the state after rolling, whereas mirror finish requires extensive polishing and buffing, significantly increasing labor and time expenses. The added cost of mirror finish is justified in applications demanding high aesthetic appeal or superior surface smoothness, but for functional or structural uses, mill finish offers a budget-friendly option. Choosing between mill finish and mirror finish hinges on balancing cost considerations with the specific project requirements for surface quality.

Maintenance Requirements for Each Finish

Mill finish metal requires minimal maintenance but is prone to oxidation and surface discoloration due to its untreated state, often needing regular cleaning to prevent buildup of dirt and corrosion. Mirror finish metal demands more frequent maintenance, including polishing and protective coatings, to preserve its reflective surface and prevent scratches and tarnishing. Choosing between the two finishes depends on balancing aesthetic appeal with the effort and cost of upkeep in various environments.

Choosing the Right Finish for Your Metal Project

Selecting the appropriate metal finish depends on the project's functional and aesthetic requirements, where mill finish offers a raw, untreated surface ideal for industrial use and cost-efficiency, while mirror finish provides a highly reflective, polished surface suitable for decorative and corrosion-resistant applications. Mill finish retains natural surface imperfections, requiring additional treatment if a smoother texture is desired, whereas mirror finish requires extensive polishing to achieve a flawless appearance and improved durability. Understanding the specific environmental exposure, maintenance needs, and visual impact guides the choice between mill finish and mirror finish for optimal metal project results.

Mill Finish vs Mirror Finish Infographic

materialdif.com

materialdif.com