Galvanization involves coating metal with a layer of zinc to protect it from corrosion through a hot-dip or electrochemical process, offering long-lasting rust resistance for outdoor applications. Electroplating deposits a thin layer of metal, such as chromium or nickel, onto a substrate using an electric current, enhancing both aesthetics and surface hardness. While galvanization is primarily used for corrosion prevention, electroplating provides decorative finishes and improved wear resistance on various metal objects.

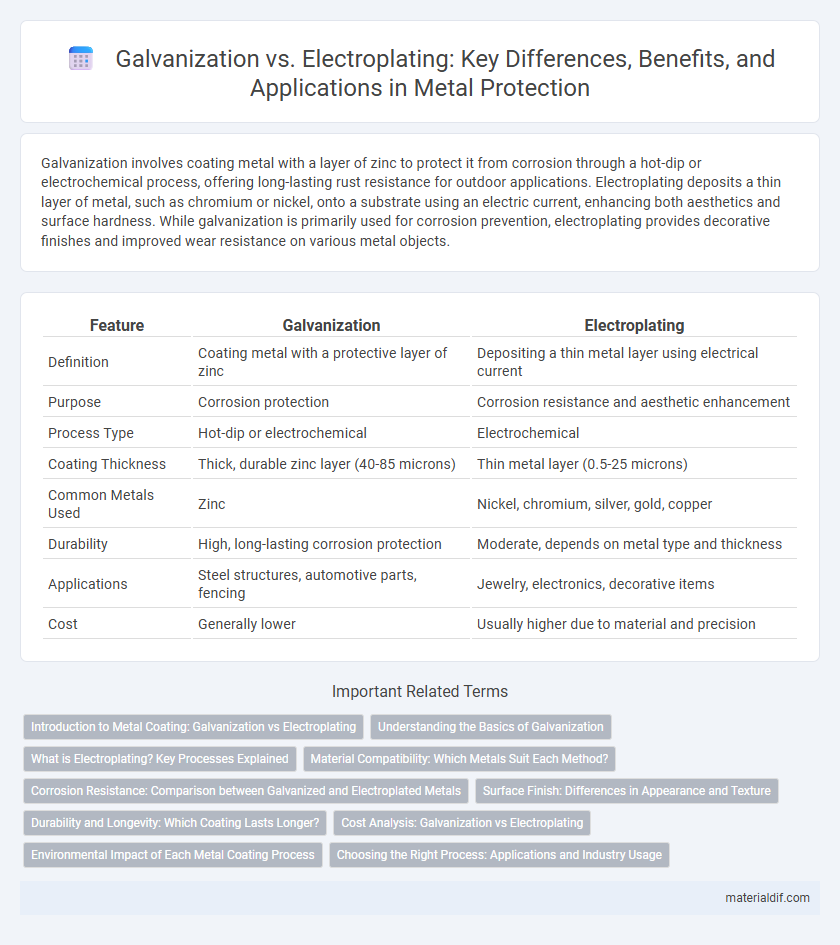

Table of Comparison

| Feature | Galvanization | Electroplating |

|---|---|---|

| Definition | Coating metal with a protective layer of zinc | Depositing a thin metal layer using electrical current |

| Purpose | Corrosion protection | Corrosion resistance and aesthetic enhancement |

| Process Type | Hot-dip or electrochemical | Electrochemical |

| Coating Thickness | Thick, durable zinc layer (40-85 microns) | Thin metal layer (0.5-25 microns) |

| Common Metals Used | Zinc | Nickel, chromium, silver, gold, copper |

| Durability | High, long-lasting corrosion protection | Moderate, depends on metal type and thickness |

| Applications | Steel structures, automotive parts, fencing | Jewelry, electronics, decorative items |

| Cost | Generally lower | Usually higher due to material and precision |

Introduction to Metal Coating: Galvanization vs Electroplating

Galvanization involves coating metal, usually steel or iron, with a protective layer of zinc to prevent rust and corrosion through a hot-dip or electro-galvanizing process. Electroplating uses electrical currents to deposit a thin layer of metal such as nickel, chromium, or gold onto a substrate, enhancing appearance, corrosion resistance, and wear properties. Both metal coating techniques significantly extend the lifespan of metal components in industrial, automotive, and construction applications by providing durable surface protection.

Understanding the Basics of Galvanization

Galvanization involves coating steel or iron with a protective layer of zinc to prevent rust and corrosion, primarily through hot-dip galvanizing or electro-galvanizing processes. This method provides long-lasting protection by forming a robust, sacrificial barrier that withstands environmental damage better than electroplating, which uses a thin metal layer deposited via electrical current. Understanding the zinc layer's role in galvanization highlights its effectiveness in industrial applications requiring durable, corrosion-resistant metal surfaces.

What is Electroplating? Key Processes Explained

Electroplating is a metal finishing process where a thin layer of metal is deposited onto the surface of a substrate using an electric current. Key processes involved include surface preparation, where the substrate is cleaned and polished to ensure adhesion; immersion in an electrolytic bath containing metal ions; and application of electric current, which causes metal cations to reduce and deposit onto the substrate. This method enhances corrosion resistance, improves wearability, and provides decorative appeal to metal components.

Material Compatibility: Which Metals Suit Each Method?

Galvanization predominantly suits iron and steel substrates, providing corrosion resistance through a zinc coating that adheres well to these ferrous metals. Electroplating is highly versatile, compatible with a broad range of metals including copper, brass, aluminum, and stainless steel, allowing for precise layering of metals like chromium, nickel, and silver. Selection depends on the base metal's chemical properties and the desired protective or decorative outcome, influencing adhesion and durability in each treatment.

Corrosion Resistance: Comparison between Galvanized and Electroplated Metals

Galvanization provides a robust corrosion-resistant zinc coating that sacrifices itself to protect the underlying metal, making it highly effective for outdoor and industrial applications. Electroplating offers a thinner, often less durable protective layer, which can wear off over time and expose the base metal to corrosion. Galvanized metals generally outperform electroplated ones in long-term corrosion resistance, especially in harsh environmental conditions.

Surface Finish: Differences in Appearance and Texture

Galvanization produces a rougher, matte surface finish due to the thick layer of zinc coating, offering robust corrosion resistance ideal for outdoor metal structures. Electroplating results in a smoother, shinier finish by depositing a thin metal layer such as chrome or nickel, enhancing aesthetic appeal and surface uniformity. The visual and tactile differences between galvanization and electroplating directly impact the metal's performance and suitability in various industrial and decorative applications.

Durability and Longevity: Which Coating Lasts Longer?

Galvanization provides superior durability by forming a thick, corrosion-resistant zinc layer that protects steel through sacrificial corrosion, often lasting decades in harsh environments. Electroplating offers a thinner metal coating, which can enhance appearance but generally wears faster and may require reapplication to maintain protection. For long-term corrosion resistance and longevity, galvanization remains the preferred choice, especially for outdoor and industrial applications.

Cost Analysis: Galvanization vs Electroplating

Galvanization typically offers a more cost-effective solution for corrosion protection on large steel structures due to its lower labor and material expenses compared to electroplating. Electroplating involves higher costs driven by complex equipment, precise control of plating thickness, and the use of expensive metals like chromium or nickel. Budget decisions between galvanization and electroplating often depend on factors such as application scale, desired finish quality, and long-term durability requirements.

Environmental Impact of Each Metal Coating Process

Galvanization uses a zinc coating to protect steel from corrosion, producing less toxic waste compared to electroplating, which often involves hazardous heavy metals such as chromium, nickel, or cadmium. The galvanization process is generally more environmentally friendly due to its lower energy consumption and reduced release of harmful chemicals into water sources. Electroplating generates wastewater containing toxic metal ions requiring advanced treatment to prevent soil and water contamination.

Choosing the Right Process: Applications and Industry Usage

Galvanization provides a thick, corrosion-resistant zinc coating ideal for outdoor structures, automotive parts, and construction materials, offering long-lasting protection in harsh environments. Electroplating allows precise control over coating thickness and metal type, making it suitable for decorative finishes, electronics, and aerospace components where conductivity and appearance are critical. Selecting between galvanization and electroplating depends on factors like environmental exposure, mechanical requirements, and desired aesthetic, guiding industries from manufacturing to electronics in applying the optimal surface treatment.

Galvanization vs Electroplating Infographic

materialdif.com

materialdif.com