Sheet metal fabrication involves cutting, bending, and assembling flat metal sheets into various shapes and products, offering high customization and versatility. Metal stamping uses specialized dies and presses to quickly produce large quantities of uniform metal parts, making it ideal for mass production. Choosing between the two depends on the project scale, complexity, and cost-effectiveness requirements.

Table of Comparison

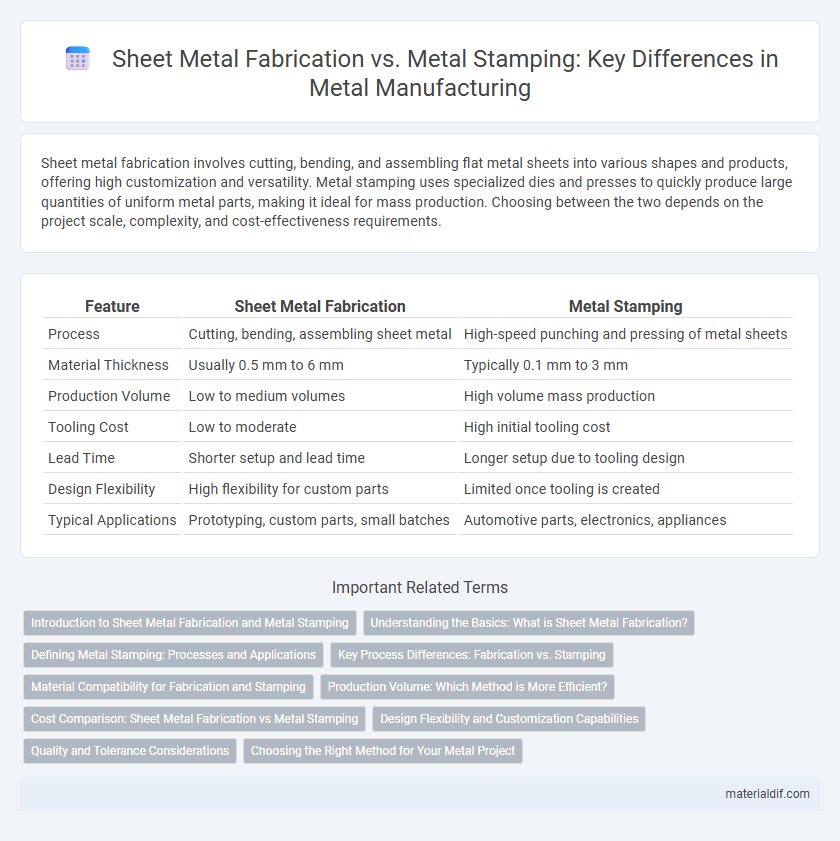

| Feature | Sheet Metal Fabrication | Metal Stamping |

|---|---|---|

| Process | Cutting, bending, assembling sheet metal | High-speed punching and pressing of metal sheets |

| Material Thickness | Usually 0.5 mm to 6 mm | Typically 0.1 mm to 3 mm |

| Production Volume | Low to medium volumes | High volume mass production |

| Tooling Cost | Low to moderate | High initial tooling cost |

| Lead Time | Shorter setup and lead time | Longer setup due to tooling design |

| Design Flexibility | High flexibility for custom parts | Limited once tooling is created |

| Typical Applications | Prototyping, custom parts, small batches | Automotive parts, electronics, appliances |

Introduction to Sheet Metal Fabrication and Metal Stamping

Sheet metal fabrication involves cutting, bending, and assembling flat metal sheets into specific shapes using processes like shearing, punching, and welding. Metal stamping uses high-pressure dies and presses to form metal into precise shapes through blanking, embossing, and coining, ideal for high-volume production. Both techniques enhance manufacturing efficiency but differ in complexity, production speed, and suitability for custom versus mass-produced components.

Understanding the Basics: What is Sheet Metal Fabrication?

Sheet metal fabrication involves cutting, bending, and assembling thin metal sheets into various shapes and structures using techniques such as shearing, punching, and welding. This process allows for customized and complex designs tailored to specific applications across industries like automotive, aerospace, and construction. Unlike metal stamping, which primarily focuses on high-volume production of uniform parts, sheet metal fabrication emphasizes versatility and precision in creating detailed, low to medium-volume components.

Defining Metal Stamping: Processes and Applications

Metal stamping involves the precise shaping of sheet metal using dies and presses to create specific parts or components, often in high volumes. This process includes various techniques such as blanking, embossing, bending, and coining, enabling the production of complex shapes with tight tolerances. Metal stamping is widely applied in automotive manufacturing, electronics, and appliance industries due to its efficiency and repeatability.

Key Process Differences: Fabrication vs. Stamping

Sheet metal fabrication involves shaping and assembling metal sheets through processes like cutting, bending, and welding, providing versatile customization for complex designs. Metal stamping uses high-speed presses and dies to punch or form metal sheets into precise shapes, ideal for large-volume production with consistent accuracy. While fabrication emphasizes manual and machine-aided customization, stamping excels in rapid, repeatable manufacturing with minimal post-processing.

Material Compatibility for Fabrication and Stamping

Sheet metal fabrication accommodates a wide range of materials, including aluminum, stainless steel, and copper alloys, offering versatility in thickness and size for custom projects. Metal stamping excels with high-volume production of consistent parts, primarily suitable for ductile metals like brass, steel, and aluminum sheets with uniform thickness. Material compatibility determines the choice between fabrication's flexibility for complex shapes and stamping's efficiency for repetitive, standardized components.

Production Volume: Which Method is More Efficient?

Sheet metal fabrication excels in low to medium production volumes due to its flexibility in creating customized parts with minimal setup time. Metal stamping is more efficient for high production volumes as it uses pre-made dies to rapidly produce consistent, complex shapes with lower per-unit costs. Production volume significantly impacts method selection, with stamping favored for large runs and fabrication preferred for smaller batch sizes.

Cost Comparison: Sheet Metal Fabrication vs Metal Stamping

Sheet metal fabrication typically incurs higher costs for low to medium production volumes due to labor-intensive processes such as cutting, bending, and welding. Metal stamping offers significant cost advantages in high-volume production runs, with lower per-unit costs driven by automation and faster cycle times. Tooling expenses for metal stamping are substantial upfront, but these are amortized over large quantities, making it more economical for mass production compared to the flexible but costlier sheet metal fabrication.

Design Flexibility and Customization Capabilities

Sheet metal fabrication offers superior design flexibility and customization capabilities by accommodating complex geometries and varied thicknesses through processes like cutting, bending, and welding. Metal stamping excels in high-volume production with consistent precision but is limited in design adaptability due to reliance on fixed tooling and dies. Choosing between sheet metal fabrication and metal stamping depends on project requirements for intricate designs versus mass production efficiency.

Quality and Tolerance Considerations

Sheet metal fabrication offers greater flexibility in achieving complex geometries with tight tolerances, making it ideal for custom or low-volume projects requiring high precision. Metal stamping excels in producing high-volume parts with consistent quality and precise tolerances due to its repeatable die process, reducing variability. Quality in metal stamping is maintained through rigorous die maintenance and process control, whereas sheet metal fabrication demands skilled craftsmanship and advanced machinery to ensure dimensional accuracy and surface finish.

Choosing the Right Method for Your Metal Project

Sheet metal fabrication offers versatile customization through cutting, bending, and assembling processes, ideal for complex, low-volume projects requiring precision and flexibility. Metal stamping excels in high-volume production runs by using dies to create uniform parts quickly and cost-effectively, making it suitable for automotive, aerospace, and electronics industries. Selecting the right method depends on project scale, design complexity, material type, and budget constraints, ensuring optimal efficiency and quality in metal manufacturing.

Sheet Metal Fabrication vs Metal Stamping Infographic

materialdif.com

materialdif.com