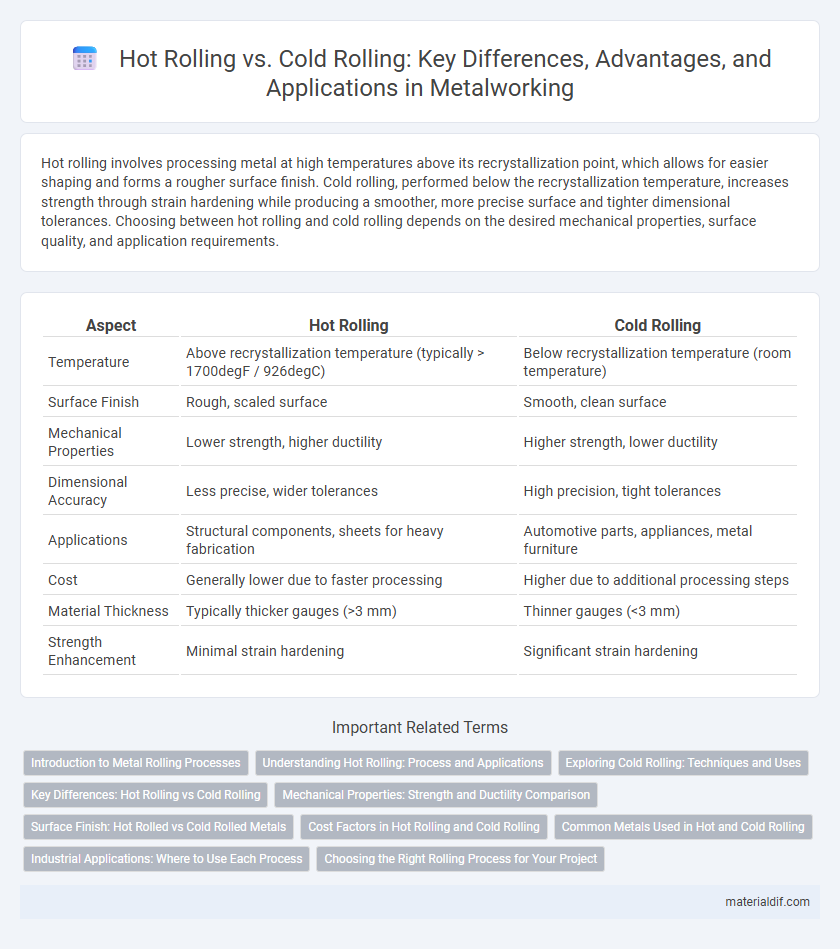

Hot rolling involves processing metal at high temperatures above its recrystallization point, which allows for easier shaping and forms a rougher surface finish. Cold rolling, performed below the recrystallization temperature, increases strength through strain hardening while producing a smoother, more precise surface and tighter dimensional tolerances. Choosing between hot rolling and cold rolling depends on the desired mechanical properties, surface quality, and application requirements.

Table of Comparison

| Aspect | Hot Rolling | Cold Rolling |

|---|---|---|

| Temperature | Above recrystallization temperature (typically > 1700degF / 926degC) | Below recrystallization temperature (room temperature) |

| Surface Finish | Rough, scaled surface | Smooth, clean surface |

| Mechanical Properties | Lower strength, higher ductility | Higher strength, lower ductility |

| Dimensional Accuracy | Less precise, wider tolerances | High precision, tight tolerances |

| Applications | Structural components, sheets for heavy fabrication | Automotive parts, appliances, metal furniture |

| Cost | Generally lower due to faster processing | Higher due to additional processing steps |

| Material Thickness | Typically thicker gauges (>3 mm) | Thinner gauges (<3 mm) |

| Strength Enhancement | Minimal strain hardening | Significant strain hardening |

Introduction to Metal Rolling Processes

Metal rolling processes involve shaping metals by passing them through rollers to reduce thickness and improve mechanical properties. Hot rolling occurs at temperatures above the metal's recrystallization point, allowing significant deformation with less force and enhancing ductility, while cold rolling is conducted below recrystallization temperatures, increasing strength and surface finish through strain hardening. Both methods are essential in manufacturing, with hot rolling mainly used for bulk shaping and cold rolling for precise, high-quality finishes.

Understanding Hot Rolling: Process and Applications

Hot rolling involves deforming metal above its recrystallization temperature, typically over 1700degF (927degC), allowing significant shape changes without cracking. This process produces large structural components like beams and rails with improved ductility and reduced internal stresses. Common applications include steel plates, sheets, and strips used in construction, automotive manufacturing, and heavy machinery.

Exploring Cold Rolling: Techniques and Uses

Cold rolling involves deforming metal sheets or strips below their recrystallization temperature, enhancing surface finish and mechanical properties such as strength and hardness. Key techniques include reversing mills, tandem mills, and skin pass rolling, each offering precise control over thickness and surface texture. Cold-rolled metals are extensively used in automotive panels, appliances, and metal furniture due to their improved dimensional accuracy and superior formability compared to hot-rolled counterparts.

Key Differences: Hot Rolling vs Cold Rolling

Hot rolling involves processing metal above its recrystallization temperature, resulting in easier shaping and improved ductility, while cold rolling is done below this temperature, enhancing surface finish and mechanical strength through strain hardening. Key differences include grain structure refinement in cold rolling, which leads to higher tensile strength, contrasted with the coarser grains from hot rolling that improve formability. Surface quality also varies, with cold rolling producing smoother, more precise dimensions compared to the rougher finishes typical of hot-rolled metals.

Mechanical Properties: Strength and Ductility Comparison

Hot rolling produces metals with lower strength but higher ductility due to the recrystallization process that reduces internal stresses and refines grain structure. Cold rolling significantly increases strength through strain hardening while decreasing ductility by introducing dislocations and residual stresses. The choice between hot and cold rolling depends on the specific application requirements for mechanical performance in steel or aluminum products.

Surface Finish: Hot Rolled vs Cold Rolled Metals

Hot rolled metals exhibit a rougher, scaled surface due to exposure to high temperatures during processing, resulting in lower dimensional accuracy and less refined finish. Cold rolled metals maintain a smooth, shiny surface with enhanced surface quality because the process occurs at room temperature, providing precise thickness control and improved mechanical properties. The choice between hot rolled and cold rolled metals significantly impacts the final product's aesthetic appeal and suitability for applications requiring superior surface finish.

Cost Factors in Hot Rolling and Cold Rolling

Hot rolling generally incurs lower production costs due to reduced energy consumption and simpler processing equipment compared to cold rolling. Cold rolling involves higher costs from additional steps such as annealing and surface finishing, alongside increased energy use for precise temperature control. Material waste tends to be lower in cold rolling, but the overall expense is dominated by labor and equipment maintenance intricacies.

Common Metals Used in Hot and Cold Rolling

Steel, aluminum, and copper are the most common metals used in both hot rolling and cold rolling processes due to their excellent mechanical properties and versatility. Hot rolling is primarily employed for metals like steel and aluminum alloys to improve ductility and reduce thickness at elevated temperatures. Cold rolling is favored for producing high-precision sheets and strips, especially in stainless steel, aluminum, and copper, offering enhanced surface finish and increased strength.

Industrial Applications: Where to Use Each Process

Hot rolling is ideal for large structural components like beams, rails, and pipes due to its ability to produce metal with excellent workability and reduced internal stresses. Cold rolling excels in manufacturing precision parts such as automotive body panels, appliances, and metal furniture where superior surface finish, tighter tolerances, and increased strength are essential. Industrial applications leverage hot rolling for bulk material production and heavy fabrication, while cold rolling is preferred for high-quality, finished products requiring enhanced mechanical properties.

Choosing the Right Rolling Process for Your Project

Selecting the appropriate rolling process depends on the desired material properties and application requirements. Hot rolling offers improved ductility and reduced internal stresses, making it ideal for large-scale structural components, while cold rolling provides superior surface finish and increased strength suited for precise, high-tolerance parts. Evaluating factors like thickness reduction, dimensional accuracy, and mechanical performance guides the optimal decision between hot rolling and cold rolling for metal fabrication projects.

Hot Rolling vs Cold Rolling Infographic

materialdif.com

materialdif.com