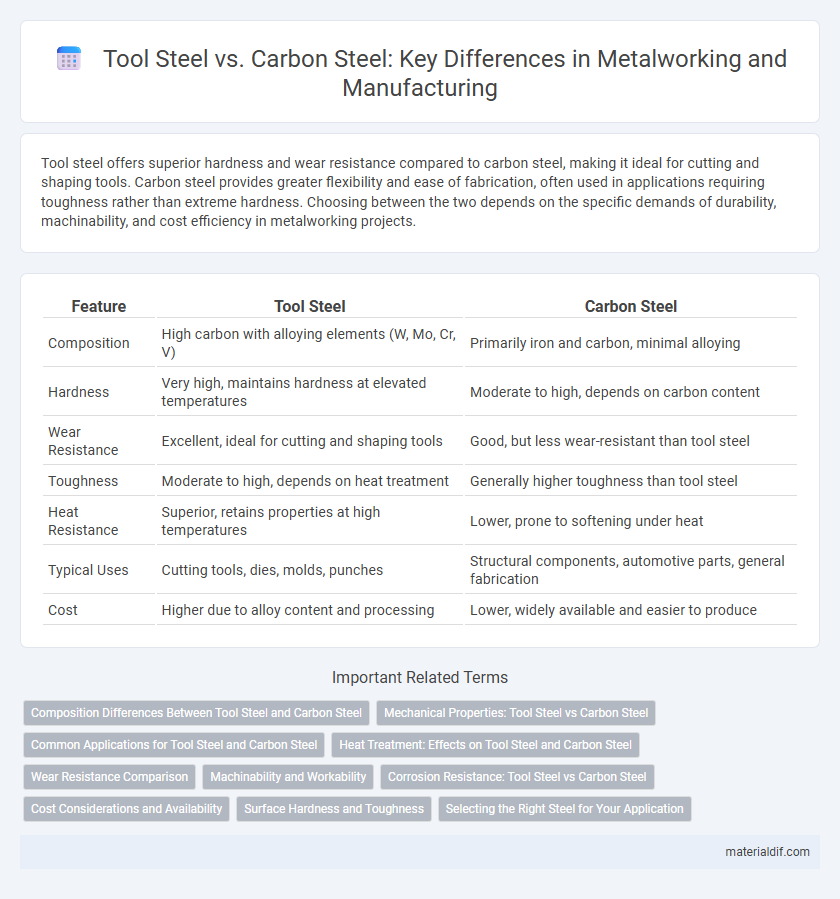

Tool steel offers superior hardness and wear resistance compared to carbon steel, making it ideal for cutting and shaping tools. Carbon steel provides greater flexibility and ease of fabrication, often used in applications requiring toughness rather than extreme hardness. Choosing between the two depends on the specific demands of durability, machinability, and cost efficiency in metalworking projects.

Table of Comparison

| Feature | Tool Steel | Carbon Steel |

|---|---|---|

| Composition | High carbon with alloying elements (W, Mo, Cr, V) | Primarily iron and carbon, minimal alloying |

| Hardness | Very high, maintains hardness at elevated temperatures | Moderate to high, depends on carbon content |

| Wear Resistance | Excellent, ideal for cutting and shaping tools | Good, but less wear-resistant than tool steel |

| Toughness | Moderate to high, depends on heat treatment | Generally higher toughness than tool steel |

| Heat Resistance | Superior, retains properties at high temperatures | Lower, prone to softening under heat |

| Typical Uses | Cutting tools, dies, molds, punches | Structural components, automotive parts, general fabrication |

| Cost | Higher due to alloy content and processing | Lower, widely available and easier to produce |

Composition Differences Between Tool Steel and Carbon Steel

Tool steel contains higher amounts of alloying elements such as tungsten, molybdenum, chromium, and vanadium compared to carbon steel, which primarily consists of iron and carbon. These alloying elements in tool steel enhance hardness, wear resistance, and heat resistance, making it suitable for cutting and shaping tools. Carbon steel, with its simpler composition typically ranging from 0.02% to 2.1% carbon, offers strength and ductility but lacks the specialized properties provided by the alloying elements in tool steel.

Mechanical Properties: Tool Steel vs Carbon Steel

Tool steel exhibits higher hardness, wear resistance, and toughness compared to carbon steel, making it ideal for cutting, shaping, and forming applications. Carbon steel offers greater ductility and ease of machining but generally lacks the superior strength and heat resistance of tool steel. The alloying elements in tool steel, such as tungsten, molybdenum, and vanadium, significantly enhance its mechanical properties, distinguishing it from the simpler composition of carbon steel.

Common Applications for Tool Steel and Carbon Steel

Tool steel is primarily used for manufacturing cutting tools, molds, dies, and precision instruments due to its high hardness and wear resistance. Carbon steel finds common applications in construction, automotive components, and general machine parts because of its strength and affordability. Both materials are essential in industries requiring specific mechanical properties tailored to tool performance or structural integrity.

Heat Treatment: Effects on Tool Steel and Carbon Steel

Tool steel undergoes specialized heat treatment processes such as quenching and tempering to develop high hardness, wear resistance, and toughness critical for cutting and shaping tools. Carbon steel benefits from heat treatment by improving hardness and strength but generally lacks the alloying elements necessary to maintain toughness at elevated temperatures, limiting its tool performance. The precise control of heat treatment parameters in tool steel ensures optimal microstructure transformation, enhancing durability and resistance to deformation.

Wear Resistance Comparison

Tool steel exhibits significantly higher wear resistance compared to carbon steel due to its alloying elements like tungsten, molybdenum, and vanadium that form hard carbides enhancing durability. Carbon steel, primarily composed of iron and carbon, lacks these alloying elements, making it more susceptible to abrasion and deformation under heavy use. The enhanced wear resistance of tool steel makes it ideal for cutting, shaping, and tooling applications where longevity and toughness are critical.

Machinability and Workability

Tool steel offers superior machinability compared to carbon steel due to its alloy composition, including elements like tungsten, molybdenum, and vanadium that enhance hardness and wear resistance. Carbon steel provides better workability with easier forming and welding processes, as it contains less alloying elements and has lower hardness. For precision machining and high-strength applications, tool steel is preferable, while carbon steel suits tasks requiring easier shaping and moderate strength.

Corrosion Resistance: Tool Steel vs Carbon Steel

Tool steel exhibits superior corrosion resistance compared to carbon steel due to its alloying elements such as chromium, vanadium, and molybdenum, which form protective oxides on the surface. Carbon steel, with its higher carbon content but minimal alloying, tends to rust more quickly when exposed to moisture and oxygen. The enhanced corrosion resistance in tool steel extends its durability and suitability for precision tools and industrial applications where oxidation resistance is critical.

Cost Considerations and Availability

Tool steel generally has a higher cost compared to carbon steel due to its alloy composition and specialized manufacturing processes. Carbon steel is more widely available and produced in larger quantities, making it a cost-effective option for many applications. The choice between tool steel and carbon steel depends on balancing budget constraints with performance requirements in specific industrial uses.

Surface Hardness and Toughness

Tool steel exhibits superior surface hardness compared to carbon steel due to its higher alloy content, enabling enhanced wear resistance and precision in cutting applications. Carbon steel offers greater toughness, making it more resistant to impact and less prone to brittle failure under heavy loads. The balance between surface hardness and toughness determines the optimal steel choice for specific industrial tools and machinery components.

Selecting the Right Steel for Your Application

Choosing between tool steel and carbon steel depends on the specific requirements of your application, such as hardness, wear resistance, and toughness. Tool steel, known for its high hardness and durability, is ideal for cutting, molding, and shaping tools where precision and longevity are critical. Carbon steel offers better ductility and is more cost-effective, making it suitable for structural components and applications where flexibility and affordability are prioritized.

Tool Steel vs Carbon Steel Infographic

materialdif.com

materialdif.com