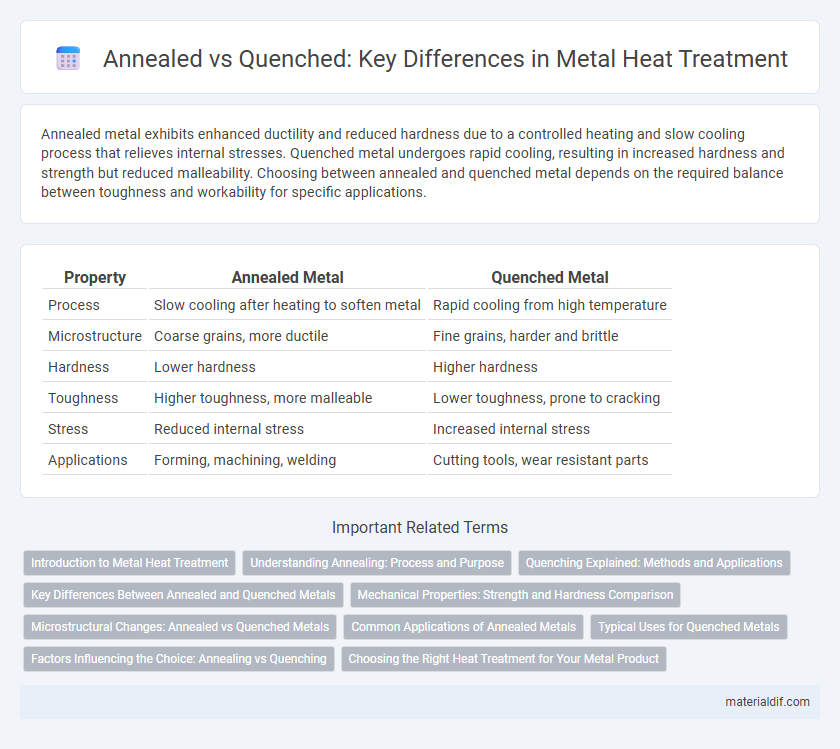

Annealed metal exhibits enhanced ductility and reduced hardness due to a controlled heating and slow cooling process that relieves internal stresses. Quenched metal undergoes rapid cooling, resulting in increased hardness and strength but reduced malleability. Choosing between annealed and quenched metal depends on the required balance between toughness and workability for specific applications.

Table of Comparison

| Property | Annealed Metal | Quenched Metal |

|---|---|---|

| Process | Slow cooling after heating to soften metal | Rapid cooling from high temperature |

| Microstructure | Coarse grains, more ductile | Fine grains, harder and brittle |

| Hardness | Lower hardness | Higher hardness |

| Toughness | Higher toughness, more malleable | Lower toughness, prone to cracking |

| Stress | Reduced internal stress | Increased internal stress |

| Applications | Forming, machining, welding | Cutting tools, wear resistant parts |

Introduction to Metal Heat Treatment

Annealed metals undergo a controlled heating process followed by slow cooling to enhance ductility and reduce hardness, improving machinability and relieving internal stresses. Quenched metals experience rapid cooling from a high temperature, typically in water or oil, resulting in increased hardness and strength but reduced ductility. These heat treatment methods are essential for tailoring the mechanical properties of metals to specific industrial applications.

Understanding Annealing: Process and Purpose

Annealing is a heat treatment process that involves heating metal to a specific temperature, maintaining it for a period, and then cooling it slowly to remove internal stresses and improve ductility. This process refines the grain structure, enhancing the metal's machinability and electrical conductivity while reducing hardness and brittleness. Understanding annealing is essential for optimizing metal properties for applications requiring improved formability and toughness.

Quenching Explained: Methods and Applications

Quenching is a rapid cooling process used to increase metal hardness and strength by transforming its microstructure, typically involving immersion in water, oil, or air. Common quenching methods include water quenching for maximum hardness, oil quenching for reduced cracking risk, and air quenching for slower cooling rates, each tailored to specific alloy properties. This technique is widely applied in tool manufacturing, automotive components, and aerospace parts to enhance wear resistance and mechanical performance.

Key Differences Between Annealed and Quenched Metals

Annealed metals undergo a controlled heating and slow cooling process that reduces hardness and improves ductility by relieving internal stresses. Quenched metals, however, are rapidly cooled from a high temperature, increasing hardness and strength while often reducing ductility due to the formation of martensite. The key differences lie in their mechanical properties: annealing enhances malleability and toughness, whereas quenching results in a harder, more brittle microstructure.

Mechanical Properties: Strength and Hardness Comparison

Annealed metals exhibit lower strength and hardness due to their softened microstructure, which enhances ductility and reduces internal stresses. Quenched metals significantly increase strength and hardness by forming a martensitic structure, resulting in improved wear resistance and durability. This heat treatment difference makes quenched metals ideal for applications requiring high mechanical performance, while annealed metals suit processes that need malleability.

Microstructural Changes: Annealed vs Quenched Metals

Annealed metals exhibit a coarse, equiaxed grain structure with reduced dislocation density, resulting from slow cooling that allows atoms to rearrange into a stable configuration. Quenched metals display a fine, martensitic or bainitic microstructure formed by rapid cooling, trapping atoms in a distorted lattice that increases hardness and strength. These microstructural changes directly influence mechanical properties, with annealing enhancing ductility and quenched metals improving hardness and tensile strength.

Common Applications of Annealed Metals

Annealed metals are widely used in applications requiring enhanced ductility and reduced hardness, making them ideal for manufacturing automotive components, electrical wiring, and metal forming processes. The annealing process reduces internal stresses, improving machinability and allowing metals like steel and copper to be shaped without cracking. Commonly found in construction, aerospace, and electronics, annealed metals provide reliable performance where flexibility and strength balance is critical.

Typical Uses for Quenched Metals

Quenched metals are commonly used in applications requiring enhanced hardness and strength, such as cutting tools, automotive components, and wear-resistant machinery parts. The rapid cooling process increases tensile strength and fatigue resistance, making quenched steel ideal for gears, springs, and structural elements subjected to high stress. These properties enable quenched metals to perform effectively in industrial environments demanding durability and impact resistance.

Factors Influencing the Choice: Annealing vs Quenching

The choice between annealed and quenched metal depends on factors such as desired mechanical properties, including hardness and ductility, and the specific application requirements. Annealing improves metal ductility and reduces internal stresses through slow cooling, making it suitable for parts requiring flexibility and machinability. Quenching involves rapid cooling to increase hardness and strength but induces brittleness, which is preferable for wear-resistant components or tools subjected to high stress.

Choosing the Right Heat Treatment for Your Metal Product

Choosing between annealed and quenched heat treatments depends on the desired metal properties; annealing softens the metal, enhancing ductility and reducing internal stress, making it ideal for machining or forming processes. Quenching rapidly cools the metal, increasing hardness and strength but reducing ductility, suitable for wear-resistant applications. Understanding the specific performance requirements of the metal product ensures the selection of the optimal heat treatment for durability and functionality.

Annealed vs Quenched Infographic

materialdif.com

materialdif.com