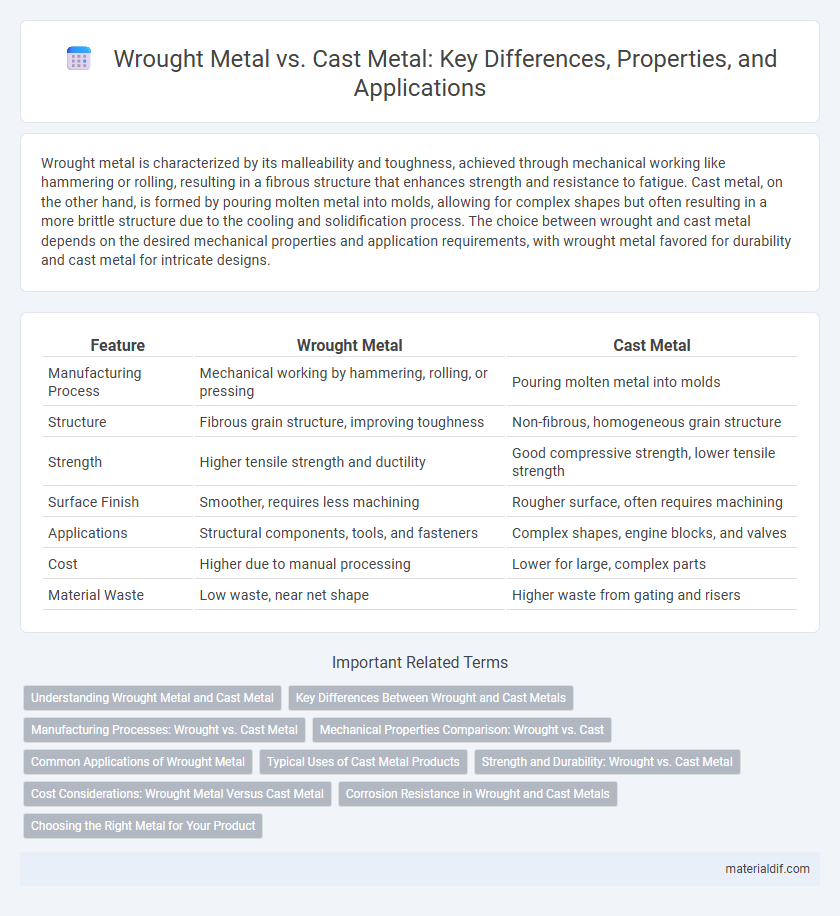

Wrought metal is characterized by its malleability and toughness, achieved through mechanical working like hammering or rolling, resulting in a fibrous structure that enhances strength and resistance to fatigue. Cast metal, on the other hand, is formed by pouring molten metal into molds, allowing for complex shapes but often resulting in a more brittle structure due to the cooling and solidification process. The choice between wrought and cast metal depends on the desired mechanical properties and application requirements, with wrought metal favored for durability and cast metal for intricate designs.

Table of Comparison

| Feature | Wrought Metal | Cast Metal |

|---|---|---|

| Manufacturing Process | Mechanical working by hammering, rolling, or pressing | Pouring molten metal into molds |

| Structure | Fibrous grain structure, improving toughness | Non-fibrous, homogeneous grain structure |

| Strength | Higher tensile strength and ductility | Good compressive strength, lower tensile strength |

| Surface Finish | Smoother, requires less machining | Rougher surface, often requires machining |

| Applications | Structural components, tools, and fasteners | Complex shapes, engine blocks, and valves |

| Cost | Higher due to manual processing | Lower for large, complex parts |

| Material Waste | Low waste, near net shape | Higher waste from gating and risers |

Understanding Wrought Metal and Cast Metal

Wrought metal is characterized by being mechanically worked through processes such as hammering, rolling, or forging, resulting in a fibrous structure that enhances its strength and ductility. Cast metal, on the other hand, is produced by melting the metal and pouring it into molds, creating components with complex shapes but often more brittle and less uniform due to rapid cooling. Understanding these differences in microstructure and production methods is crucial for selecting the appropriate metal type for applications requiring specific mechanical properties and durability.

Key Differences Between Wrought and Cast Metals

Wrought metal is shaped by mechanical processes such as hammering, rolling, or pressing, resulting in a denser structure with improved tensile strength and ductility compared to cast metal, which is formed by pouring molten metal into molds. Cast metals tend to have a more brittle microstructure with potential porosity and are better suited for complex shapes and intricate designs, while wrought metals excel in applications requiring toughness and fatigue resistance. The fundamental difference lies in the manufacturing method, where wrought metal undergoes plastic deformation enhancing grain alignment, whereas cast metal solidifies in a mold leading to a granular microstructure.

Manufacturing Processes: Wrought vs. Cast Metal

Wrought metal undergoes mechanical working processes such as rolling, forging, and extrusion, which refine its grain structure and enhance mechanical properties like strength and toughness. Cast metal is produced by melting and pouring molten metal into molds, creating complex shapes but often resulting in coarser grain structures with potential internal defects. The manufacturing process of wrought metal allows for better control over material properties, while casting offers versatility in shape and size for components.

Mechanical Properties Comparison: Wrought vs. Cast

Wrought metal exhibits superior mechanical properties such as higher tensile strength, toughness, and ductility compared to cast metal due to its refined grain structure achieved through mechanical working processes. Cast metals often present a coarse, brittle microstructure with lower impact resistance and reduced fatigue strength, making them less suitable for dynamic or load-bearing applications. The enhanced mechanical performance of wrought metals results from the elimination of casting defects and alignment of grain flow, which contribute to improved hardness and elongation characteristics.

Common Applications of Wrought Metal

Wrought metal is extensively used in applications requiring high strength and ductility, such as structural beams, automotive components, and aerospace hardware. Its fine grain structure and superior toughness make it ideal for tools, decorative ironwork, and hardware like hinges and fasteners. Common industries utilizing wrought metal include construction, transportation, and manufacturing, where precision and durability are critical.

Typical Uses of Cast Metal Products

Cast metal products are widely used in industries requiring complex shapes and high strength, such as automotive engine blocks, machinery components, and pipe fittings. Their excellent ability to form intricate designs makes them ideal for valves, pumps, and heavy equipment parts that demand durability and wear resistance. Cast metals also play a crucial role in construction, providing structural components and decorative architectural elements with precise dimensions and robustness.

Strength and Durability: Wrought vs. Cast Metal

Wrought metal typically exhibits greater strength and durability due to its fibrous grain structure formed through plastic deformation, which enhances resistance to impact and fatigue. Cast metal, produced by pouring molten metal into molds, often has a more brittle microstructure with potential porosity, resulting in lower tensile strength but excellent compressive strength for intricate shapes. The choice between wrought and cast metal depends on the application's mechanical demands, with wrought metal preferred for high-stress components and cast metal favored for complex geometries requiring corrosion resistance.

Cost Considerations: Wrought Metal Versus Cast Metal

Wrought metal typically incurs higher production costs due to extensive labor and machining processes, whereas cast metal benefits from lower manufacturing expenses by using molds for mass production. The complexity of wrought metal fabrication, including forging and rolling, contributes to increased material waste and energy consumption, impacting overall cost efficiency. Cast metal, while more economical, may require additional finishing work to address surface imperfections, balancing initial savings with post-production expenditures.

Corrosion Resistance in Wrought and Cast Metals

Wrought metal typically exhibits superior corrosion resistance compared to cast metal due to its refined grain structure and reduced porosity. The working processes in wrought metal minimize defects and increase density, enhancing its resistance to chemical and environmental degradation. Cast metals often contain micro-shrinkages and inclusions that can act as initiation points for corrosion, making them less durable in harsh conditions.

Choosing the Right Metal for Your Product

Wrought metal offers superior strength and ductility due to its forged and worked structure, ideal for applications requiring durability and precision shaping. Cast metal, formed by pouring molten metal into molds, excels in complex shapes and intricate details but may have lower tensile strength. Selecting the right metal depends on balancing factors like mechanical performance, design complexity, and manufacturing cost for optimal product functionality.

Wrought Metal vs Cast Metal Infographic

materialdif.com

materialdif.com