Brass, an alloy of copper and zinc, offers excellent machinability and corrosion resistance, making it ideal for decorative and musical instrument applications. Bronze, primarily composed of copper and tin, provides superior strength and wear resistance, preferred for heavy-duty industrial parts and sculptures. Both metals exhibit distinct properties that determine their suitability depending on the required durability and aesthetic appeal.

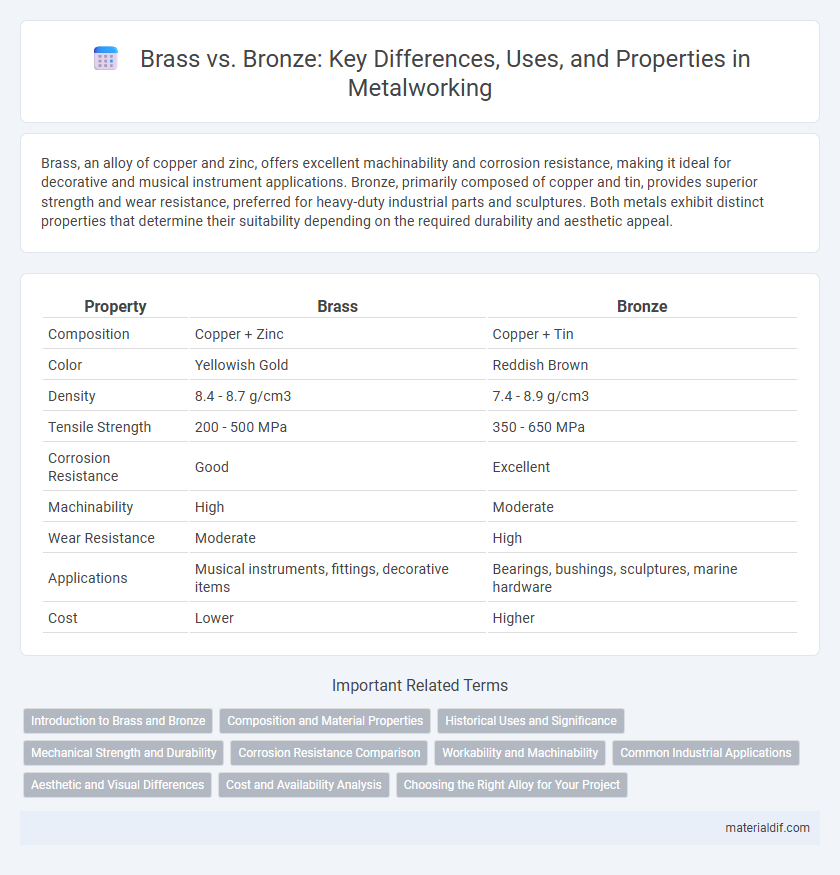

Table of Comparison

| Property | Brass | Bronze |

|---|---|---|

| Composition | Copper + Zinc | Copper + Tin |

| Color | Yellowish Gold | Reddish Brown |

| Density | 8.4 - 8.7 g/cm3 | 7.4 - 8.9 g/cm3 |

| Tensile Strength | 200 - 500 MPa | 350 - 650 MPa |

| Corrosion Resistance | Good | Excellent |

| Machinability | High | Moderate |

| Wear Resistance | Moderate | High |

| Applications | Musical instruments, fittings, decorative items | Bearings, bushings, sculptures, marine hardware |

| Cost | Lower | Higher |

Introduction to Brass and Bronze

Brass is an alloy primarily composed of copper and zinc, known for its bright gold-like appearance and excellent machinability. Bronze, made mainly from copper and tin, displays superior corrosion resistance and a reddish-brown hue. Both metals have been historically essential in applications ranging from musical instruments to industrial machinery, with distinct physical and chemical properties influencing their use.

Composition and Material Properties

Brass is primarily an alloy of copper and zinc, typically containing 55%-95% copper with varying zinc content, which gives it excellent machinability and corrosion resistance. Bronze mainly consists of copper and tin, usually around 88% copper with 12% tin, resulting in higher strength, hardness, and wear resistance compared to brass. The differing compositions influence their applications; brass is favored for decorative and low-friction components, while bronze suits heavy-duty mechanical parts requiring durability.

Historical Uses and Significance

Brass, an alloy of copper and zinc, was widely used in ancient Egypt and Rome for decorative art, musical instruments, and coinage due to its bright gold-like appearance and corrosion resistance. Bronze, composed primarily of copper and tin, played a critical role in the Bronze Age, enabling the creation of advanced tools, weapons, and sculptures, which significantly influenced early human civilization and warfare. Both metals exhibit unique historical significance, with bronze marking the transition to complex societies and brass symbolizing advancements in metallurgy and artistic expression.

Mechanical Strength and Durability

Brass offers excellent mechanical strength with good tensile properties, making it suitable for applications requiring moderate durability and resistance to wear. Bronze, composed primarily of copper and tin, generally exhibits higher hardness and superior resistance to corrosion and fatigue, enhancing its durability in harsh environments. The choice between brass and bronze depends on the specific requirements for mechanical strength and long-term durability in different industrial uses.

Corrosion Resistance Comparison

Brass, an alloy of copper and zinc, offers excellent corrosion resistance in atmospheric and mild industrial environments but can suffer dezincification in highly corrosive or marine conditions. Bronze, primarily composed of copper and tin, exhibits superior resistance to saltwater corrosion and is often preferred for marine applications and underwater components due to its toughness and durability. The inherent chemical stability of bronze makes it more suitable than brass for prolonged exposure to aggressive environments where corrosion resistance is critical.

Workability and Machinability

Brass, an alloy of copper and zinc, exhibits superior workability due to its malleability and ductility, making it easier to form and shape compared to bronze. Bronze, primarily composed of copper and tin, tends to be harder and more brittle, which can reduce its machinability and increase tool wear during processing. Manufacturers often prefer brass for intricate machining tasks requiring precision, while bronze is favored in applications demanding greater strength and wear resistance despite its tougher machinability.

Common Industrial Applications

Brass, an alloy of copper and zinc, is widely used in plumbing fittings, musical instruments, and decorative hardware due to its excellent machinability and corrosion resistance. Bronze, primarily composed of copper and tin, finds common applications in bearings, bushings, marine components, and sculptures because of its superior strength and wear resistance. Both alloys are essential in industrial environments but are chosen based on specific mechanical properties and exposure conditions.

Aesthetic and Visual Differences

Brass exhibits a bright, golden-yellow sheen with high reflectivity, making it favored for decorative items where a shiny, polished appearance is desired. Bronze typically has a deeper, reddish-brown tone with a slightly duller matte finish, lending a more antique or rustic aesthetic often used in sculptures and classical art. The color intensity of brass can range from pale to rich yellow, while bronze varies from dark brown to coppery, both metals developing unique patinas that enhance their visual appeal over time.

Cost and Availability Analysis

Brass generally costs less than bronze due to its simpler alloy composition, mainly copper and zinc, which utilizes more abundant raw materials. Bronze, an alloy primarily of copper and tin, often incurs higher expenses because of tin's relative scarcity and fluctuating market prices. Availability of brass is typically higher worldwide, making it a more accessible choice for large-scale industrial applications compared to the more specialized supply chain of bronze.

Choosing the Right Alloy for Your Project

Brass, an alloy of copper and zinc, offers excellent machinability and corrosion resistance, making it ideal for decorative items and plumbing components. Bronze, primarily composed of copper and tin, provides superior strength and wear resistance, suited for heavy-duty applications such as bearings and marine hardware. Selecting the right alloy depends on balancing factors like mechanical properties, environmental exposure, and aesthetic requirements to ensure optimal performance in your project.

Brass vs Bronze Infographic

materialdif.com

materialdif.com