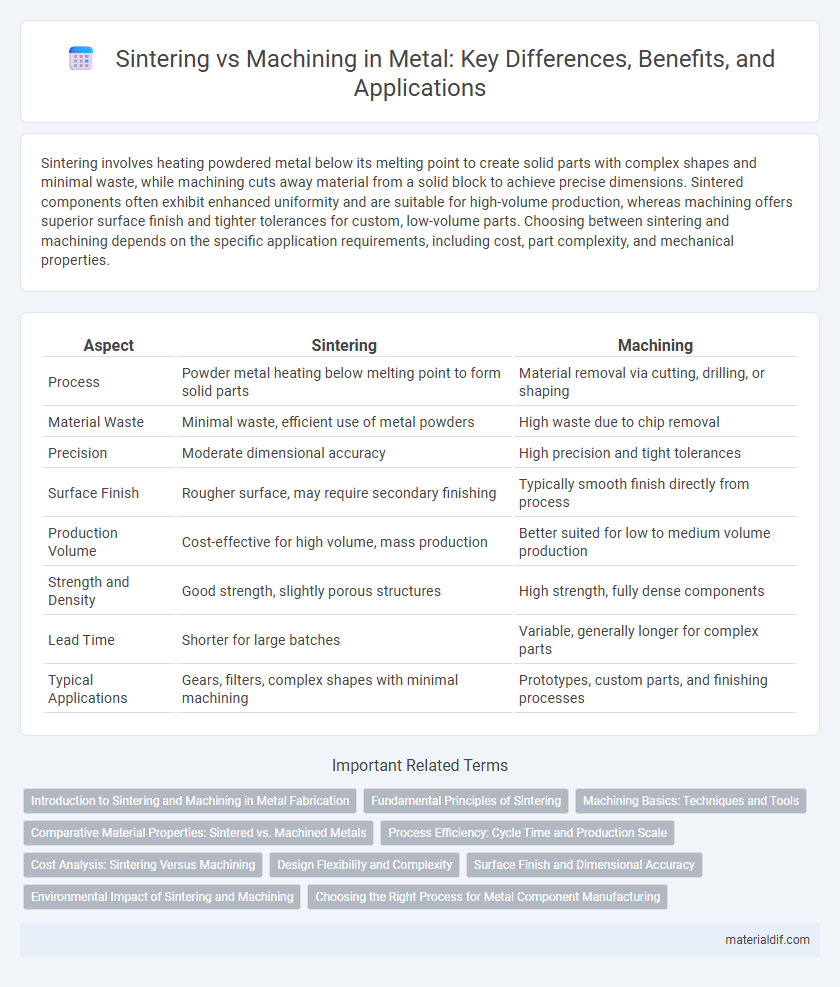

Sintering involves heating powdered metal below its melting point to create solid parts with complex shapes and minimal waste, while machining cuts away material from a solid block to achieve precise dimensions. Sintered components often exhibit enhanced uniformity and are suitable for high-volume production, whereas machining offers superior surface finish and tighter tolerances for custom, low-volume parts. Choosing between sintering and machining depends on the specific application requirements, including cost, part complexity, and mechanical properties.

Table of Comparison

| Aspect | Sintering | Machining |

|---|---|---|

| Process | Powder metal heating below melting point to form solid parts | Material removal via cutting, drilling, or shaping |

| Material Waste | Minimal waste, efficient use of metal powders | High waste due to chip removal |

| Precision | Moderate dimensional accuracy | High precision and tight tolerances |

| Surface Finish | Rougher surface, may require secondary finishing | Typically smooth finish directly from process |

| Production Volume | Cost-effective for high volume, mass production | Better suited for low to medium volume production |

| Strength and Density | Good strength, slightly porous structures | High strength, fully dense components |

| Lead Time | Shorter for large batches | Variable, generally longer for complex parts |

| Typical Applications | Gears, filters, complex shapes with minimal machining | Prototypes, custom parts, and finishing processes |

Introduction to Sintering and Machining in Metal Fabrication

Sintering is a metal fabrication process that involves heating powdered metal below its melting point to fuse particles into a solid, dense material with enhanced structural integrity. Machining, in contrast, is a subtractive process that shapes metal parts by removing material through cutting, drilling, or grinding to achieve precise dimensions and surface finishes. Sintering promotes complex geometries and material efficiency, while machining provides tight tolerances and smooth finishes crucial for high-performance metal components.

Fundamental Principles of Sintering

Sintering involves heating metal powders below their melting point to enable atomic diffusion, causing particles to bond and form a solid mass without liquefying the material. This process enhances material density, mechanical strength, and thermal conductivity by reducing porosity through particle coalescence. Unlike machining, which removes material, sintering creates near-net-shape components by consolidating powders, optimizing material usage and minimizing waste.

Machining Basics: Techniques and Tools

Machining involves removing material from metal workpieces using tools such as lathes, milling machines, and CNC routers to achieve precise shapes and dimensions. Common techniques include turning, drilling, milling, and grinding, each employing specific cutting tools like carbide inserts, drills, and end mills designed for durability and accuracy. Mastery of feed rates, cutting speeds, and tool geometry optimizes surface finish and dimensional tolerance, critical for high-performance metal components.

Comparative Material Properties: Sintered vs. Machined Metals

Sintered metals exhibit enhanced porosity and uniform microstructure, resulting in improved wear resistance and self-lubrication capabilities compared to machined metals, which typically have higher density and superior dimensional accuracy. The sintering process allows for tailored material properties such as controlled hardness and strength by adjusting particle size and sintering temperature, whereas machining relies on cutting and shaping solid metal, often causing residual stress and material waste. Consequently, sintered metals are preferred in applications demanding complex geometries and lightweight components, while machined metals excel in precision parts requiring smooth surface finishes and tight tolerances.

Process Efficiency: Cycle Time and Production Scale

Sintering offers rapid cycle times by enabling the simultaneous consolidation of metal powders into complex shapes, significantly boosting production scale for high-volume manufacturing. Machining requires longer cycle times due to material removal processes and tool changes, making it less efficient for mass production but suitable for low-volume, high-precision parts. Optimizing process efficiency involves balancing sintering's speed and scalability with machining's flexibility and precision depending on production demands.

Cost Analysis: Sintering Versus Machining

Sintering offers a cost-effective solution for producing complex metal parts with minimal material waste and lower energy consumption compared to traditional machining processes. Machining involves higher labor costs and longer production times due to material removal and tool wear, increasing overall expenses. In large-scale manufacturing, sintering reduces unit costs significantly through efficient material utilization and reduced post-processing requirements.

Design Flexibility and Complexity

Sintering offers superior design flexibility by enabling the production of complex geometries and intricate internal structures that are challenging or impossible to achieve through traditional machining. Machining excels in creating precise external features but is limited in handling complex internal cavities or thin-walled components without compromising structural integrity. The additive nature of sintering supports intricate designs in industries such as aerospace and automotive, where optimized weight and material usage are critical.

Surface Finish and Dimensional Accuracy

Sintering produces a porous surface texture that may require secondary finishing processes to achieve smoothness, while machining delivers superior surface finish directly by removing material with precision cutting tools. Dimensional accuracy in machining is generally higher due to controlled material removal, whereas sintering relies heavily on powder compaction and shrinkage control, often resulting in slight dimensional variations. Choosing between sintering and machining hinges on the required surface quality and tightness of tolerances for metal components.

Environmental Impact of Sintering and Machining

Sintering significantly reduces environmental impact by minimizing material waste and lowering energy consumption compared to machining, which often generates substantial scrap metal and requires higher power levels for cutting processes. The powder metallurgy process inherent in sintering enables precise shaping with reduced emissions, whereas machining involves extensive use of cutting fluids that contribute to chemical waste. Sintering also supports recycling of metal powders, enhancing sustainability, while machining's reliance on fossil fuel-based energy sources amplifies its carbon footprint.

Choosing the Right Process for Metal Component Manufacturing

Selecting the optimal process for metal component manufacturing requires evaluating sintering and machining based on material properties, production volume, and desired precision. Sintering offers cost-effective mass production with excellent material utilization and uniform microstructure, ideal for complex shapes and high-volume parts. Machining provides superior dimensional accuracy and surface finish for low-volume or highly detailed components but often incurs higher material waste and longer cycle times.

Sintering vs Machining Infographic

materialdif.com

materialdif.com