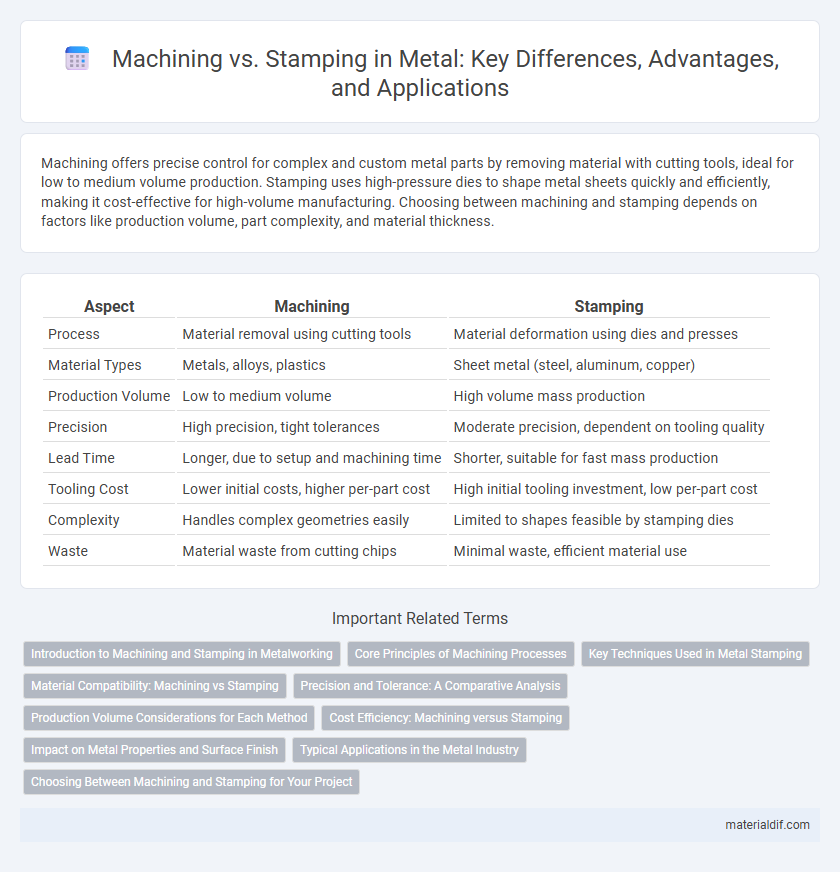

Machining offers precise control for complex and custom metal parts by removing material with cutting tools, ideal for low to medium volume production. Stamping uses high-pressure dies to shape metal sheets quickly and efficiently, making it cost-effective for high-volume manufacturing. Choosing between machining and stamping depends on factors like production volume, part complexity, and material thickness.

Table of Comparison

| Aspect | Machining | Stamping |

|---|---|---|

| Process | Material removal using cutting tools | Material deformation using dies and presses |

| Material Types | Metals, alloys, plastics | Sheet metal (steel, aluminum, copper) |

| Production Volume | Low to medium volume | High volume mass production |

| Precision | High precision, tight tolerances | Moderate precision, dependent on tooling quality |

| Lead Time | Longer, due to setup and machining time | Shorter, suitable for fast mass production |

| Tooling Cost | Lower initial costs, higher per-part cost | High initial tooling investment, low per-part cost |

| Complexity | Handles complex geometries easily | Limited to shapes feasible by stamping dies |

| Waste | Material waste from cutting chips | Minimal waste, efficient material use |

Introduction to Machining and Stamping in Metalworking

Machining in metalworking involves removing material from a workpiece using tools such as lathes, mills, or drills to achieve precise shapes and dimensions. Stamping, on the other hand, uses dies and presses to form or cut metal sheets into desired shapes through deformation processes. Both techniques are vital for manufacturing metal components, with machining offering high precision and stamping providing rapid, cost-effective production for high-volume parts.

Core Principles of Machining Processes

Machining processes involve removing material from a metal workpiece through precise cutting, drilling, or grinding to achieve desired shapes and tolerances. Core principles include the control of cutting speed, feed rate, and tool geometry, which directly impact surface finish and dimensional accuracy. Unlike stamping, machining offers greater flexibility for complex geometries and tight tolerances but typically requires longer cycle times and higher operational costs.

Key Techniques Used in Metal Stamping

Metal stamping involves techniques such as blanking, piercing, bending, flanging, embossing, and coining to shape and cut metal sheets precisely. These key methods enable high-volume production of complex parts with consistent accuracy and minimal material waste. Machining typically removes material via cutting tools, whereas stamping forms parts by deforming the metal, making stamping more efficient for large-scale manufacturing.

Material Compatibility: Machining vs Stamping

Machining offers superior material compatibility by accommodating a wide range of metals including hard alloys, stainless steel, and titanium with precise control over dimensions. Stamping is highly effective for thinner, ductile metals such as aluminum and mild steel but encounters limitations with harder or thicker materials due to tooling wear and deformation risks. Material selection for machining or stamping depends on metal properties, production volume, and required part complexity.

Precision and Tolerance: A Comparative Analysis

Machining offers superior precision and tighter tolerances compared to stamping, making it ideal for complex metal parts requiring intricate details. CNC machining can consistently achieve tolerances as low as +-0.001 inches, whereas stamping typically maintains tolerances around +-0.005 inches due to die limitations. This makes machining the preferred choice for applications where exact dimensions and surface finish are critical.

Production Volume Considerations for Each Method

Machining offers precision and flexibility ideal for low to medium production volumes, where customization and detailed features are critical. Stamping excels in high-volume production due to its rapid cycle times and lower per-unit costs once tooling is established. Choosing the suitable method depends on balancing initial setup expenses with anticipated production quantity to optimize efficiency and cost-effectiveness.

Cost Efficiency: Machining versus Stamping

Machining generally incurs higher initial costs due to tooling and setup expenses but offers greater flexibility for low to medium production volumes, making it cost-efficient for custom or complex metal parts. Stamping delivers significant cost savings in high-volume production with low per-unit costs after initial die investment, ideal for uniform, repetitive parts. Evaluating volume requirements and part complexity is essential to determine the most cost-effective metal fabrication method.

Impact on Metal Properties and Surface Finish

Machining alters metal properties by removing material through cutting, which can induce residual stresses and microstructural changes, affecting hardness and ductility. Stamping, a cold-forming process, maintains the metal's grain structure and enhances strength through strain hardening but may cause surface deformation or scratches. Surface finish from machining typically achieves higher precision and smoother textures, whereas stamping often results in rougher surfaces requiring additional finishing steps.

Typical Applications in the Metal Industry

Machining is commonly used in the metal industry for producing complex parts with tight tolerances, such as aerospace components, automotive engine parts, and custom prototypes. Stamping is ideal for high-volume production of sheet metal components like car body panels, brackets, and electronic enclosures due to its speed and cost-efficiency. Both processes are critical in manufacturing, with machining favored for precision and stamping chosen for mass production of uniform metal parts.

Choosing Between Machining and Stamping for Your Project

Choosing between machining and stamping depends on factors like production volume, precision requirements, and material type. Machining offers high precision and flexibility for low to medium volumes, ideal for complex or customized metal parts. Stamping suits high-volume production with consistent part quality, providing cost efficiency for simple to moderately complex shapes.

Machining vs Stamping Infographic

materialdif.com

materialdif.com