Galvanized metal features a protective zinc coating that prevents rust and corrosion, making it ideal for outdoor and industrial applications where durability is crucial. Painted metal offers aesthetic versatility and additional protection but may require regular maintenance as paint can chip or peel over time. Choosing between galvanized and painted metal depends on the environment and desired longevity, with galvanized providing superior corrosion resistance and painted metal allowing for customizable finishes.

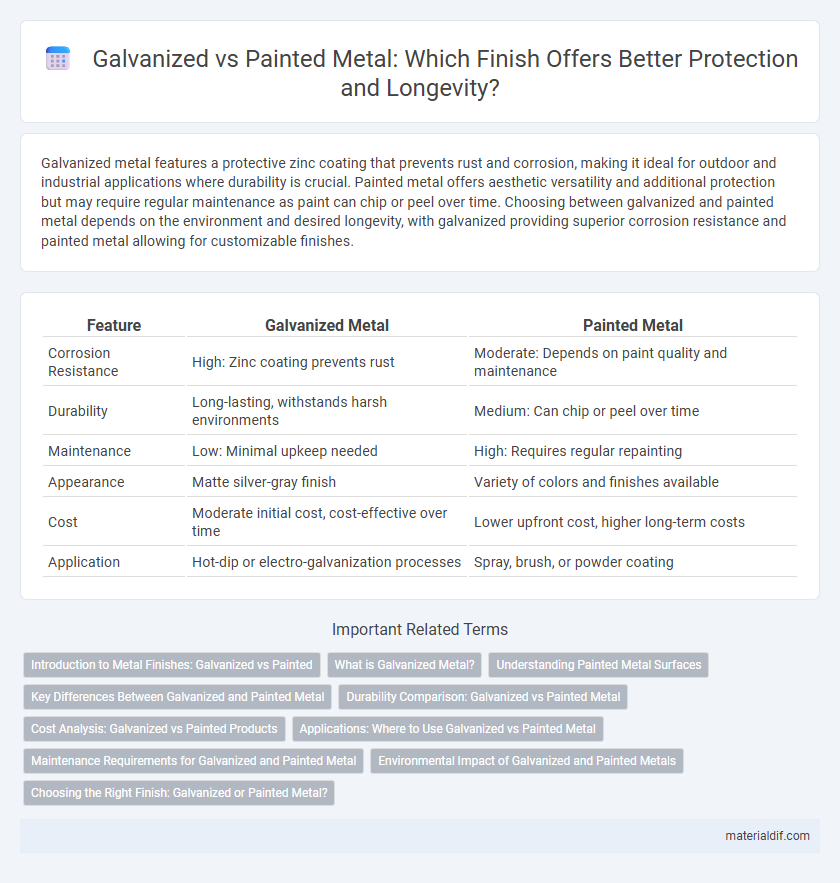

Table of Comparison

| Feature | Galvanized Metal | Painted Metal |

|---|---|---|

| Corrosion Resistance | High: Zinc coating prevents rust | Moderate: Depends on paint quality and maintenance |

| Durability | Long-lasting, withstands harsh environments | Medium: Can chip or peel over time |

| Maintenance | Low: Minimal upkeep needed | High: Requires regular repainting |

| Appearance | Matte silver-gray finish | Variety of colors and finishes available |

| Cost | Moderate initial cost, cost-effective over time | Lower upfront cost, higher long-term costs |

| Application | Hot-dip or electro-galvanization processes | Spray, brush, or powder coating |

Introduction to Metal Finishes: Galvanized vs Painted

Galvanized metal features a protective zinc coating that prevents rust and corrosion, making it ideal for outdoor applications and harsh environments. Painted metal provides a customizable finish that enhances aesthetics and offers a layer of protection but may require periodic maintenance to prevent chipping or peeling. Choosing between galvanized and painted finishes depends on factors such as durability, environmental exposure, and desired appearance.

What is Galvanized Metal?

Galvanized metal is steel or iron coated with a layer of zinc to prevent rust and corrosion, enhancing its durability and lifespan. The galvanization process typically involves hot-dip coating, where the metal is submerged in molten zinc for a robust protective barrier. This zinc layer acts as a sacrificial anode, protecting the base metal from environmental elements more effectively than paint.

Understanding Painted Metal Surfaces

Painted metal surfaces offer enhanced aesthetic versatility and corrosion resistance through protective coatings that seal the metal from environmental exposure. Unlike galvanized metal, which relies on a zinc layer for rust prevention, painted surfaces depend on high-quality primers and topcoats tailored for durability under varying weather conditions. Proper surface preparation and paint selection are critical to maximizing the lifespan and performance of painted metal in industrial and architectural applications.

Key Differences Between Galvanized and Painted Metal

Galvanized metal undergoes a zinc coating process that provides corrosion resistance by forming a protective barrier, making it ideal for outdoor and industrial applications. Painted metal relies on surface coatings for protection and aesthetic appeal, but it requires regular maintenance to prevent chipping and rust. Key differences include durability, with galvanized metal offering longer-lasting protection, and the visual finish, where painted metal allows for customizable colors and textures.

Durability Comparison: Galvanized vs Painted Metal

Galvanized metal offers superior durability by providing a protective zinc coating that resists rust and corrosion in harsh environments, extending the metal's lifespan significantly. Painted metal protects through a barrier layer that can chip, peel, or fade over time, requiring regular maintenance to maintain its appearance and corrosion resistance. In high-moisture or industrial settings, galvanized metal typically outperforms painted metal in long-term durability and corrosion protection.

Cost Analysis: Galvanized vs Painted Products

Galvanized metal typically incurs higher upfront costs due to the hot-dip galvanization process, which involves coating steel with a layer of zinc to provide long-lasting corrosion resistance. Painted metal usually offers lower initial expenses, but may require frequent maintenance and repainting over time, increasing overall lifecycle costs. When analyzing cost-effectiveness, galvanized products prove more economical for long-term durability, especially in harsh environments, whereas painted metals suit applications with budget constraints and controlled settings.

Applications: Where to Use Galvanized vs Painted Metal

Galvanized metal excels in outdoor applications like construction, roofing, and automotive parts due to its superior corrosion resistance and durability in harsh environments. Painted metal is ideal for indoor uses, decorative elements, and machinery requiring aesthetic appeal and customizable color finishes. Choosing galvanized metal suits heavy-duty, weather-exposed projects while painted metal serves well in settings demanding visual enhancement and moderate protection.

Maintenance Requirements for Galvanized and Painted Metal

Galvanized metal requires minimal maintenance due to its protective zinc coating that resists rust and corrosion over time. Painted metal demands regular inspection and touch-ups to prevent peeling, chipping, and exposure of the base metal to moisture, which can accelerate rust formation. Proper maintenance of painted surfaces includes cleaning, repainting, and addressing any scratches promptly to prolong durability and appearance.

Environmental Impact of Galvanized and Painted Metals

Galvanized metal typically has a lower environmental impact due to its long-lasting zinc coating that prevents corrosion, reducing the need for frequent replacements and minimizing waste. Painted metals often require chemical solvents and volatile organic compounds (VOCs) in their coatings, which can contribute to air pollution and pose environmental hazards during application and disposal. Zinc used in galvanization is recyclable, enhancing sustainability, whereas paint layers may complicate recycling efforts and increase environmental burdens.

Choosing the Right Finish: Galvanized or Painted Metal?

Choosing the right finish for metal depends on the application and environment; galvanized metal offers superior corrosion resistance due to its zinc coating, making it ideal for outdoor and industrial use. Painted metal provides a wider range of colors and aesthetic options, along with a protective layer that can be reapplied for maintenance. Consider durability, exposure to elements, and desired appearance when selecting between galvanized and painted metal finishes.

Galvanized vs Painted Infographic

materialdif.com

materialdif.com