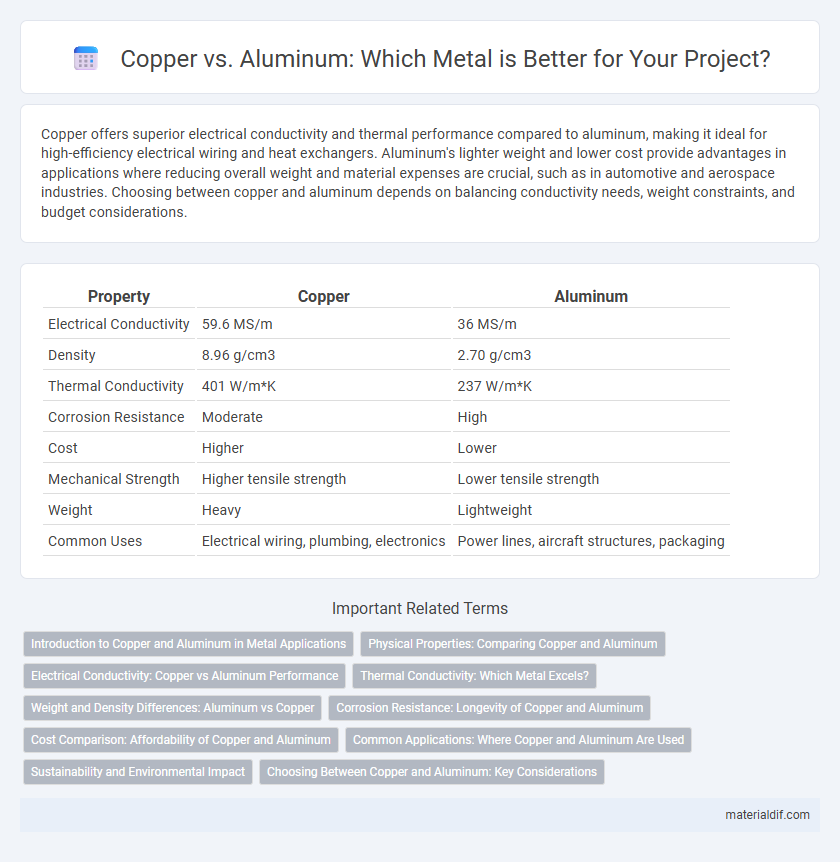

Copper offers superior electrical conductivity and thermal performance compared to aluminum, making it ideal for high-efficiency electrical wiring and heat exchangers. Aluminum's lighter weight and lower cost provide advantages in applications where reducing overall weight and material expenses are crucial, such as in automotive and aerospace industries. Choosing between copper and aluminum depends on balancing conductivity needs, weight constraints, and budget considerations.

Table of Comparison

| Property | Copper | Aluminum |

|---|---|---|

| Electrical Conductivity | 59.6 MS/m | 36 MS/m |

| Density | 8.96 g/cm3 | 2.70 g/cm3 |

| Thermal Conductivity | 401 W/m*K | 237 W/m*K |

| Corrosion Resistance | Moderate | High |

| Cost | Higher | Lower |

| Mechanical Strength | Higher tensile strength | Lower tensile strength |

| Weight | Heavy | Lightweight |

| Common Uses | Electrical wiring, plumbing, electronics | Power lines, aircraft structures, packaging |

Introduction to Copper and Aluminum in Metal Applications

Copper offers superior electrical conductivity and corrosion resistance, making it ideal for electrical wiring and plumbing systems. Aluminum provides a lightweight alternative with excellent thermal conductivity and is widely used in aerospace, automotive, and packaging industries. Both metals play crucial roles in modern metal applications due to their unique mechanical properties and versatility.

Physical Properties: Comparing Copper and Aluminum

Copper boasts higher electrical conductivity (approximately 5.96x10^7 S/m) and thermal conductivity (around 401 W/m*K) compared to aluminum, which has conductivity values of about 3.77x10^7 S/m and 237 W/m*K respectively. Copper's density (8.96 g/cm3) is more than double that of aluminum (2.70 g/cm3), making aluminum a lighter alternative for applications requiring weight reduction. Both metals exhibit excellent corrosion resistance, but copper tends to outperform aluminum in mechanical strength and durability under high-stress physical conditions.

Electrical Conductivity: Copper vs Aluminum Performance

Copper exhibits higher electrical conductivity than aluminum, with a conductivity rating of approximately 59.6 million siemens per meter (MS/m) compared to aluminum's 37.8 MS/m, making copper the preferred choice for applications requiring efficient current flow. Copper's lower resistivity (around 1.68 micro-ohm centimeters) enables reduced energy loss and better performance in electrical wiring and components. Despite aluminum's lighter weight and cost advantages, copper remains superior in critical environments demanding maximum electrical conductivity and durability.

Thermal Conductivity: Which Metal Excels?

Copper exhibits significantly higher thermal conductivity, approximately 401 W/m*K, compared to aluminum's 237 W/m*K, making copper the superior choice for efficient heat transfer. This difference allows copper to excel in applications requiring rapid heat dissipation, such as heat exchangers and electrical components. Despite aluminum's lower thermal conductivity, its lighter weight and lower cost often make it favorable for weight-sensitive or budget-conscious projects.

Weight and Density Differences: Aluminum vs Copper

Aluminum has a density of approximately 2.70 g/cm3, making it significantly lighter than copper, which has a density of about 8.96 g/cm3. This weight difference means aluminum is nearly one-third the weight of copper for the same volume, offering advantages in applications where reducing overall weight is critical. The lower density of aluminum contributes to its widespread use in industries like aerospace and automotive, where lightness and strength balance is essential.

Corrosion Resistance: Longevity of Copper and Aluminum

Copper exhibits superior corrosion resistance compared to aluminum due to its natural patina formation, which protects the underlying metal from further deterioration. Aluminum forms a thin oxide layer that provides some protection but is less durable in harsh environments, especially in acidic or saline conditions. This enhanced corrosion resistance of copper contributes significantly to its longer lifespan and reliability in applications requiring extended durability.

Cost Comparison: Affordability of Copper and Aluminum

Copper generally costs significantly more per pound than aluminum, making aluminum the more affordable option for large-scale projects where budget constraints are critical. The price difference stems from copper's higher material value and greater conductivity, which adds to its overall cost despite better performance in electrical applications. Aluminum's lower cost and lighter weight offer economic advantages, especially in construction and transportation industries where material savings yield substantial cost reductions.

Common Applications: Where Copper and Aluminum Are Used

Copper is widely used in electrical wiring, plumbing, and roofing due to its excellent conductivity and corrosion resistance, making it essential in residential and commercial construction. Aluminum is favored in power transmission lines, automotive components, and packaging industries because of its lightweight nature and good conductivity. Both metals serve critical roles in manufacturing and infrastructure, with copper dominating applications requiring superior electrical performance and aluminum preferred for weight-sensitive uses.

Sustainability and Environmental Impact

Copper offers superior recyclability with a recovery rate of over 90%, reducing the need for mining and lowering environmental degradation compared to aluminum. Aluminum production consumes more energy and generates higher greenhouse gas emissions, though its lightweight properties contribute to fuel efficiency in transportation applications. Sustainable metal sourcing increasingly favors copper due to its longevity, corrosion resistance, and lower ecological footprint throughout its lifecycle.

Choosing Between Copper and Aluminum: Key Considerations

Copper offers superior electrical conductivity and corrosion resistance, making it ideal for high-performance electrical wiring and industrial applications. Aluminum is lighter, more cost-effective, and easier to install, suited for overhead power lines and large-scale construction. When choosing between copper and aluminum, engineers weigh factors like budget, mechanical strength, conductivity requirements, and environmental conditions to determine the optimal metal for each project.

Copper vs Aluminum Infographic

materialdif.com

materialdif.com