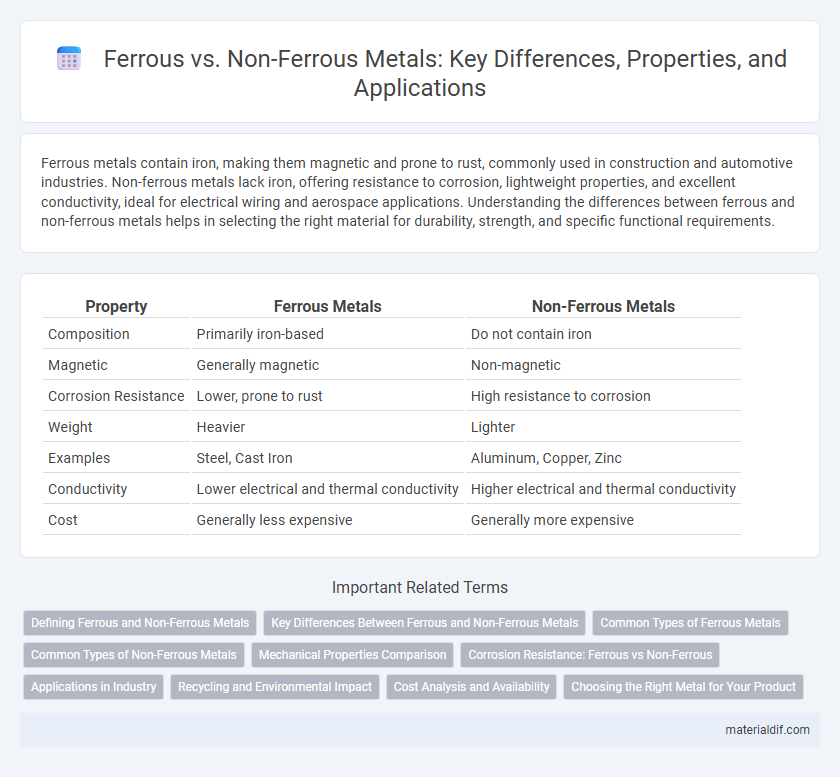

Ferrous metals contain iron, making them magnetic and prone to rust, commonly used in construction and automotive industries. Non-ferrous metals lack iron, offering resistance to corrosion, lightweight properties, and excellent conductivity, ideal for electrical wiring and aerospace applications. Understanding the differences between ferrous and non-ferrous metals helps in selecting the right material for durability, strength, and specific functional requirements.

Table of Comparison

| Property | Ferrous Metals | Non-Ferrous Metals |

|---|---|---|

| Composition | Primarily iron-based | Do not contain iron |

| Magnetic | Generally magnetic | Non-magnetic |

| Corrosion Resistance | Lower, prone to rust | High resistance to corrosion |

| Weight | Heavier | Lighter |

| Examples | Steel, Cast Iron | Aluminum, Copper, Zinc |

| Conductivity | Lower electrical and thermal conductivity | Higher electrical and thermal conductivity |

| Cost | Generally less expensive | Generally more expensive |

Defining Ferrous and Non-Ferrous Metals

Ferrous metals primarily contain iron, making them magnetic and highly durable, with common examples including steel and cast iron. Non-ferrous metals lack iron, offering superior resistance to corrosion and lighter weight, as seen in aluminum, copper, and zinc. Understanding the fundamental differences between ferrous and non-ferrous metals is essential for selecting materials based on strength, conductivity, and environmental resistance.

Key Differences Between Ferrous and Non-Ferrous Metals

Ferrous metals contain iron, making them magnetic and prone to rust, with common examples including steel and cast iron that offer high tensile strength and durability. Non-ferrous metals lack iron, which makes them corrosion-resistant, lightweight, and non-magnetic, featuring materials such as aluminum, copper, and zinc commonly used in electrical wiring and lightweight applications. The key differences between ferrous and non-ferrous metals lie in magnetic properties, susceptibility to oxidation, density, and typical industrial uses.

Common Types of Ferrous Metals

Common types of ferrous metals include carbon steel, stainless steel, and cast iron, each with distinct properties and uses. Carbon steel is widely used for construction and manufacturing due to its strength and affordability, while stainless steel offers corrosion resistance essential in medical and kitchen applications. Cast iron provides excellent compressive strength and is commonly found in machinery and automotive parts.

Common Types of Non-Ferrous Metals

Common types of non-ferrous metals include aluminum, copper, lead, zinc, and nickel, each valued for unique properties such as corrosion resistance, electrical conductivity, and lightweight strength. Aluminum is widely used in aerospace and automotive industries due to its excellent strength-to-weight ratio, while copper is essential for electrical wiring because of its superior electrical conductance. Lead serves in batteries and radiation shielding, zinc is primarily used for galvanizing to prevent rust, and nickel is crucial in stainless steel production for enhanced durability and corrosion resistance.

Mechanical Properties Comparison

Ferrous metals, composed primarily of iron and carbon, exhibit high tensile strength and magnetic properties, making them ideal for construction and heavy machinery applications. Non-ferrous metals such as aluminum, copper, and titanium generally offer superior corrosion resistance, lower density, and better electrical conductivity, which enhances their usability in aerospace, electronics, and automotive industries. The mechanical properties of ferrous metals typically include greater hardness and wear resistance, while non-ferrous metals excel in malleability and thermal conductivity.

Corrosion Resistance: Ferrous vs Non-Ferrous

Ferrous metals, primarily composed of iron, are prone to rust and corrosion when exposed to moisture and oxygen due to their iron content. Non-ferrous metals such as aluminum, copper, and stainless steel exhibit superior corrosion resistance, making them ideal for environments with high humidity or exposure to chemicals. This inherent corrosion resistance in non-ferrous metals results from their ability to form stable oxide layers that protect the underlying metal from further degradation.

Applications in Industry

Ferrous metals, primarily composed of iron, are extensively used in construction, automotive manufacturing, and heavy machinery due to their strength and magnetic properties. Non-ferrous metals like aluminum, copper, and zinc are preferred in aerospace, electrical wiring, and corrosion-resistant applications because of their lightweight, conductivity, and resistance to rust. Industrial sectors rely on the specific characteristics of ferrous and non-ferrous metals to optimize performance, durability, and cost-efficiency in manufacturing processes.

Recycling and Environmental Impact

Ferrous metals, such as steel and iron, are highly recyclable and can be melted down repeatedly without degradation, significantly reducing the demand for mining and lowering environmental impact. Non-ferrous metals like aluminum and copper also offer excellent recyclability, with aluminum recycling saving up to 95% of the energy required for primary production, thereby minimizing greenhouse gas emissions. Recycling both ferrous and non-ferrous metals mitigates waste in landfills, conserves natural resources, and reduces pollution, making metal recycling a critical component of sustainable industrial practices.

Cost Analysis and Availability

Ferrous metals, primarily composed of iron, are generally more cost-effective due to abundant global reserves and well-established extraction processes, making them widely available in construction and manufacturing industries. Non-ferrous metals like aluminum, copper, and titanium often carry higher prices driven by limited deposits and more energy-intensive refining methods, despite their superior corrosion resistance and conductivity. Availability of non-ferrous metals is subject to geopolitical factors and recycling efficiency, influencing long-term cost fluctuations in electronics and aerospace sectors.

Choosing the Right Metal for Your Product

Ferrous metals, primarily composed of iron, offer superior strength and magnetic properties, making them ideal for construction, automotive, and heavy machinery applications where durability is critical. Non-ferrous metals, including aluminum, copper, and titanium, provide excellent corrosion resistance, lightweight characteristics, and high electrical conductivity, suitable for aerospace, electronics, and marine industries. Selecting the right metal depends on specific product requirements such as strength, weight, corrosion resistance, and cost-efficiency, ensuring optimal performance and longevity.

Ferrous vs Non-Ferrous Infographic

materialdif.com

materialdif.com