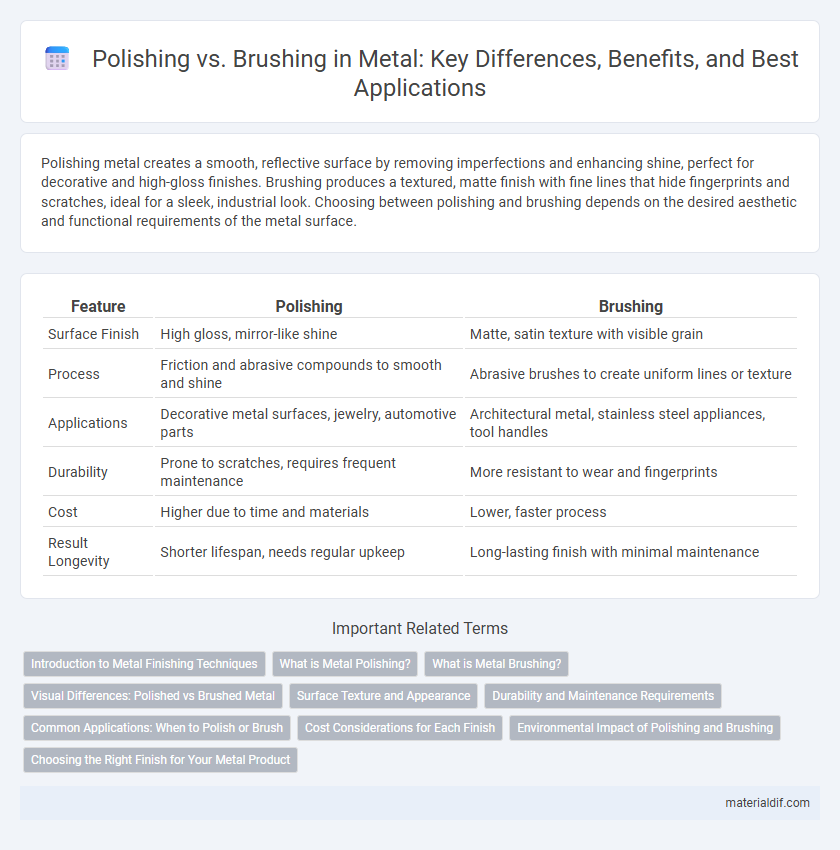

Polishing metal creates a smooth, reflective surface by removing imperfections and enhancing shine, perfect for decorative and high-gloss finishes. Brushing produces a textured, matte finish with fine lines that hide fingerprints and scratches, ideal for a sleek, industrial look. Choosing between polishing and brushing depends on the desired aesthetic and functional requirements of the metal surface.

Table of Comparison

| Feature | Polishing | Brushing |

|---|---|---|

| Surface Finish | High gloss, mirror-like shine | Matte, satin texture with visible grain |

| Process | Friction and abrasive compounds to smooth and shine | Abrasive brushes to create uniform lines or texture |

| Applications | Decorative metal surfaces, jewelry, automotive parts | Architectural metal, stainless steel appliances, tool handles |

| Durability | Prone to scratches, requires frequent maintenance | More resistant to wear and fingerprints |

| Cost | Higher due to time and materials | Lower, faster process |

| Result Longevity | Shorter lifespan, needs regular upkeep | Long-lasting finish with minimal maintenance |

Introduction to Metal Finishing Techniques

Polishing and brushing are essential metal finishing techniques used to enhance surface appearance and texture. Polishing creates a smooth, reflective finish by removing surface imperfections through abrasive materials, while brushing produces a uniform, matte texture with fine, linear scratches using abrasive brushes. These methods are chosen based on desired aesthetics, corrosion resistance, and application requirements in industries such as automotive, aerospace, and architecture.

What is Metal Polishing?

Metal polishing is the process of smoothing and shining metal surfaces by removing scratches, oxidation, and imperfections through abrasive materials or chemical treatments. This technique enhances the metal's reflective quality and durability, making it ideal for decorative or functional purposes. Polished metals exhibit a high-gloss finish that improves corrosion resistance and surface cleanliness.

What is Metal Brushing?

Metal brushing is a surface finishing technique that creates a consistent, linear texture by using abrasive brushes or pads on metal surfaces such as stainless steel and aluminum. This process removes surface imperfections and imparts a matte or satin finish, enhancing the metal's aesthetic appeal and resistance to corrosion. Brushed metal is commonly used in appliances, architectural elements, and automotive parts due to its modern and sophisticated look.

Visual Differences: Polished vs Brushed Metal

Polished metal exhibits a smooth, reflective surface with a mirror-like finish that enhances brightness and clarity. Brushed metal features a textured appearance with fine, linear scratches that create a matte effect, reducing glare and adding visual depth. The contrast between polished and brushed metal lies in the level of shininess and surface detail, influencing aesthetic choices in design and application.

Surface Texture and Appearance

Polishing produces a smooth, reflective surface by removing microscopic imperfections, resulting in a mirror-like finish ideal for aesthetics and corrosion resistance. Brushing creates a textured, matte appearance with fine parallel lines, enhancing the metal's grip and masking fingerprints or scratches. The choice between polishing and brushing depends on the desired visual effect and functional properties of the metal surface.

Durability and Maintenance Requirements

Polishing metal creates a smooth, reflective surface that enhances corrosion resistance and reduces dirt accumulation, making it easier to clean but often requiring frequent upkeep to maintain its shine. Brushing produces a textured, matte finish that effectively hides scratches and fingerprints, offering superior durability and lower maintenance in high-traffic or industrial environments. Both finishes impact longevity differently, with polishing suited for decorative applications and brushing preferred for functional, wear-resistant surfaces.

Common Applications: When to Polish or Brush

Polishing metal enhances surface smoothness and shine, making it ideal for decorative items, jewelry, and automotive parts where aesthetics are crucial. Brushing creates a uniform, matte finish with fine texture, commonly used for stainless steel appliances, architectural elements, and industrial equipment to mask fingerprints and surface imperfections. Choosing between polishing and brushing depends on whether the priority is visual appeal or functional surface texture.

Cost Considerations for Each Finish

Polishing metal surfaces requires more time and specialized equipment, resulting in higher labor and operational costs compared to brushing. Brushed finishes typically involve less intensive processes, making them more cost-effective for large-scale or industrial applications. Material type and desired finish quality also significantly impact the overall expense of each method.

Environmental Impact of Polishing and Brushing

Polishing metals often involves chemical compounds and abrasive materials that can generate hazardous waste and contribute to water pollution if not managed properly. Brushing typically uses mechanical abrasion with less chemical input, resulting in lower toxic emissions and reduced environmental footprint. Choosing brushing over polishing can minimize ecological damage by reducing chemical discharge and energy consumption in metal finishing processes.

Choosing the Right Finish for Your Metal Product

Polishing creates a smooth, reflective surface that enhances corrosion resistance and highlights the metal's natural luster, ideal for decorative purposes and high-end applications. Brushing produces a textured, matte finish with fine lines that mask imperfections and fingerprints, making it suitable for industrial or contemporary designs. Selecting the right finish depends on the metal type, usage environment, and aesthetic goals to ensure durability and visual appeal.

Polishing vs Brushing Infographic

materialdif.com

materialdif.com