Annealing involves heating metal to a specific temperature and then cooling it slowly to soften the material, improving ductility and reducing internal stresses. Tempering follows quenching by reheating the metal to a lower temperature and then cooling it, which enhances toughness while reducing brittleness. Both processes optimize metal properties but serve different purposes: annealing for softness and tempering for balanced strength and hardness.

Table of Comparison

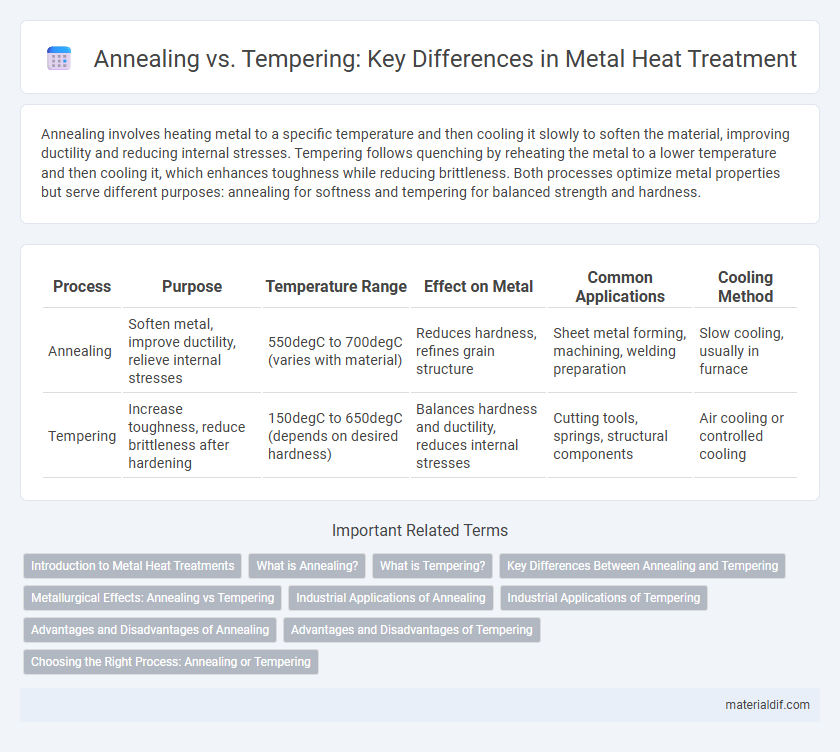

| Process | Purpose | Temperature Range | Effect on Metal | Common Applications | Cooling Method |

|---|---|---|---|---|---|

| Annealing | Soften metal, improve ductility, relieve internal stresses | 550degC to 700degC (varies with material) | Reduces hardness, refines grain structure | Sheet metal forming, machining, welding preparation | Slow cooling, usually in furnace |

| Tempering | Increase toughness, reduce brittleness after hardening | 150degC to 650degC (depends on desired hardness) | Balances hardness and ductility, reduces internal stresses | Cutting tools, springs, structural components | Air cooling or controlled cooling |

Introduction to Metal Heat Treatments

Annealing and tempering are essential metal heat treatments used to improve alloy properties by altering their microstructure. Annealing involves heating the metal to a specific temperature followed by slow cooling, which softens the metal and enhances ductility. Tempering is performed after quenching, heating the metal to a lower temperature to reduce brittleness while maintaining strength.

What is Annealing?

Annealing is a heat treatment process used to soften metal, improve its ductility, and relieve internal stresses by heating the material to a specific temperature and then allowing it to cool slowly. This process refines the metal's microstructure, enhancing machinability and reducing hardness for easier fabrication. Annealing is commonly applied to steel, copper, aluminum, and other alloys to restore workability after cold working or casting.

What is Tempering?

Tempering is a heat treatment process applied to hardened metal to improve its toughness and reduce brittleness by reheating it to a specific temperature below its critical point. This process relieves internal stresses and enhances ductility while maintaining an adequate level of hardness essential for structural performance. Tempering is crucial for optimizing the mechanical properties of steel and other alloys used in industrial applications.

Key Differences Between Annealing and Tempering

Annealing softens metal by heating it to a specific temperature and cooling it slowly, which reduces hardness and improves ductility for enhanced machinability. Tempering follows quenching and involves reheating the metal to a lower temperature to decrease brittleness while maintaining strength and toughness. Key differences include their purposes, cooling rates--slow for annealing and rapid for quenching before tempering--and resulting mechanical properties tailored for specific industrial applications.

Metallurgical Effects: Annealing vs Tempering

Annealing involves heating metal to a specific temperature and then slowly cooling it, which refines grain structure, reduces hardness, and improves ductility by relieving internal stresses. Tempering, performed after quenching, reheats hardened metal to a lower temperature to decrease brittleness while maintaining strength through controlled precipitation of carbides. Both processes alter the microstructure but differ in their metallurgical effects, with annealing promoting softness and tempering enhancing toughness.

Industrial Applications of Annealing

Annealing improves ductility and reduces hardness in metals, making it essential for industrial applications such as automotive manufacturing, aerospace components, and heavy machinery production. This heat treatment process relieves internal stresses and refines the microstructure, enhancing machinability and formability of steel and aluminum alloys. Consistent annealing ensures high-quality metal parts, critical for maintaining structural integrity and durability in demanding industrial environments.

Industrial Applications of Tempering

Tempering is widely used in industrial applications to enhance the toughness and ductility of steel after quenching, reducing brittleness while maintaining hardness. It is critical in manufacturing automotive components, aerospace parts, and heavy machinery where improved mechanical properties and resistance to impact are required. The precise control of temperature during tempering influences the microstructure, directly affecting fatigue strength and wear resistance in industrial steel products.

Advantages and Disadvantages of Annealing

Annealing enhances metal ductility and reduces hardness, making it easier to machine and form, but it can cause grain growth that may weaken strength. This heat treatment process also relieves internal stresses, improving dimensional stability while potentially increasing susceptibility to wear. The slower cooling rate of annealing compared to tempering results in a softer microstructure ideal for further processing but less suitable for high-strength applications.

Advantages and Disadvantages of Tempering

Tempering improves the toughness and ductility of steel by reducing brittleness caused by quenching, enhancing its impact resistance and machinability. However, over-tempering can lower hardness and strength, diminishing wear resistance and load-bearing capacity. The process offers controlled mechanical properties but requires precise temperature management to avoid compromising the material's performance in industrial applications.

Choosing the Right Process: Annealing or Tempering

Choosing the right heat treatment process depends on the desired mechanical properties and applications of the metal. Annealing is ideal for metals requiring enhanced ductility and reduced hardness through slow cooling, while tempering is suited for hardened steels needing increased toughness and reduced brittleness by reheating after quenching. Consider factors such as metal composition, required strength, and machinability when selecting between annealing and tempering for optimal performance.

Annealing vs Tempering Infographic

materialdif.com

materialdif.com