Alloying enhances metal properties by combining different elements to create a new material with improved strength, corrosion resistance, and durability. Tempering modifies the metal's microstructure through controlled heating and cooling, optimizing hardness and toughness without altering its chemical composition. Both processes are essential for tailoring metals to specific engineering applications, balancing performance and longevity.

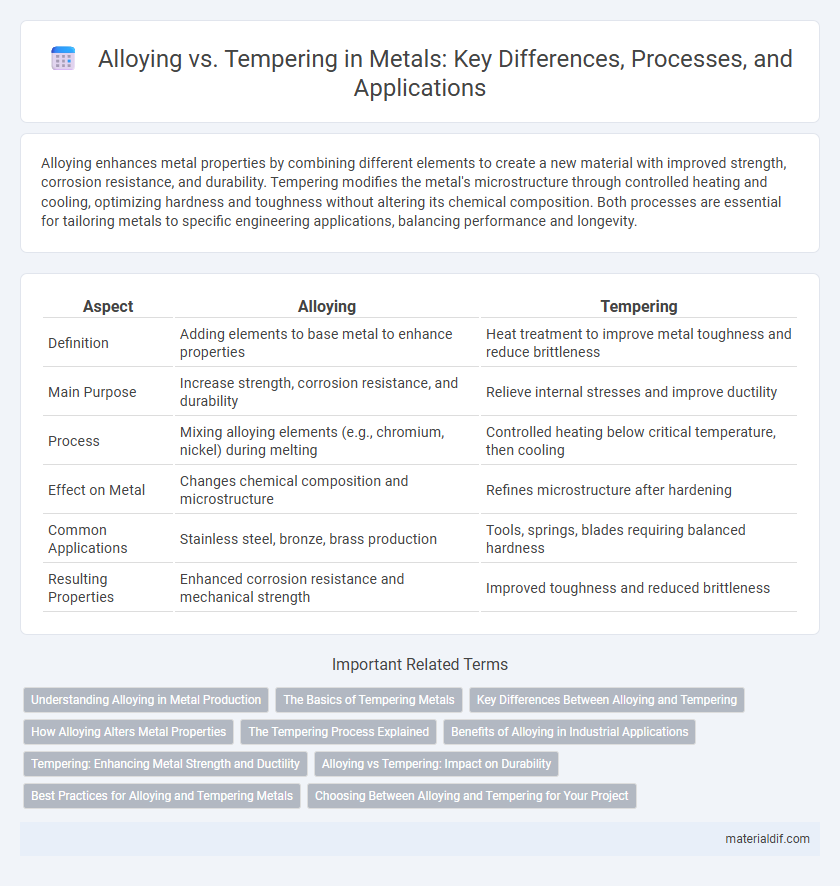

Table of Comparison

| Aspect | Alloying | Tempering |

|---|---|---|

| Definition | Adding elements to base metal to enhance properties | Heat treatment to improve metal toughness and reduce brittleness |

| Main Purpose | Increase strength, corrosion resistance, and durability | Relieve internal stresses and improve ductility |

| Process | Mixing alloying elements (e.g., chromium, nickel) during melting | Controlled heating below critical temperature, then cooling |

| Effect on Metal | Changes chemical composition and microstructure | Refines microstructure after hardening |

| Common Applications | Stainless steel, bronze, brass production | Tools, springs, blades requiring balanced hardness |

| Resulting Properties | Enhanced corrosion resistance and mechanical strength | Improved toughness and reduced brittleness |

Understanding Alloying in Metal Production

Alloying in metal production involves combining two or more metallic elements to enhance properties such as strength, corrosion resistance, and ductility. Common alloying elements include carbon in steel, aluminum in bronze, and chromium in stainless steel, each altering the metal's microstructure for targeted applications. Understanding alloying is essential for tailoring metals to specific industrial demands, influencing mechanical performance and durability.

The Basics of Tempering Metals

Tempering metals involves heating an alloy, typically steel, to a specific temperature below its critical point and then cooling it to enhance toughness and reduce brittleness without sacrificing hardness. Unlike alloying, which introduces new elements like chromium or nickel to alter metal properties at the atomic level, tempering adjusts the existing microstructure to balance strength and ductility. This controlled heat treatment process is essential for improving the performance and durability of hardened steels used in tools, machinery, and structural components.

Key Differences Between Alloying and Tempering

Alloying involves mixing different metals to create a new material with enhanced properties such as increased strength, corrosion resistance, or conductivity, whereas tempering is a heat treatment process applied to metals to improve toughness and reduce brittleness after quenching. Alloyed metals exhibit altered chemical compositions that influence their fundamental characteristics, while tempered metals undergo microstructural changes to relieve stresses and refine hardness. The key difference lies in alloying changing the material's overall composition, while tempering modifies the metal's internal structure without altering its elemental makeup.

How Alloying Alters Metal Properties

Alloying alters metal properties by introducing different elements into the base metal, resulting in enhanced strength, hardness, corrosion resistance, and thermal stability. The added alloying elements form solid solutions or intermetallic compounds that disrupt the metal's crystal lattice, improving mechanical performance and durability. This controlled modification of chemical composition tailors metals for specific industrial applications, such as aerospace, automotive, and construction.

The Tempering Process Explained

The tempering process involves heating a metal, typically steel, to a temperature below its critical point, then allowing it to cool slowly to reduce brittleness and increase toughness. This heat treatment alters the microstructure by relieving internal stresses formed during quenching, enhancing ductility without significantly compromising hardness. Unlike alloying, which changes the chemical composition of a metal, tempering modifies physical properties through controlled thermal cycles to achieve desired mechanical characteristics.

Benefits of Alloying in Industrial Applications

Alloying enhances metals by improving their mechanical properties, corrosion resistance, and thermal stability, making them ideal for demanding industrial applications. The introduction of elements like chromium, nickel, and molybdenum creates materials with superior strength and durability suited for construction, automotive, and aerospace industries. These tailored properties achieved through alloying extend component lifespan and reduce maintenance costs compared to solely tempering processes.

Tempering: Enhancing Metal Strength and Ductility

Tempering is a heat treatment process that enhances metal strength and ductility by carefully reheating quenched steel to a specific temperature below its critical point, reducing brittleness while maintaining hardness. This controlled heating adjusts the microstructure, promoting uniform grain distribution and relieving internal stresses, which improves toughness and resistance to fracture. Compared to alloying, tempering provides a cost-effective method to finely tune mechanical properties without altering chemical composition.

Alloying vs Tempering: Impact on Durability

Alloying enhances a metal's durability by incorporating elements such as chromium, nickel, or manganese, which improve corrosion resistance, hardness, and tensile strength. Tempering, a heat treatment process applied to hardened steel, reduces brittleness and enhances toughness without significantly altering chemical composition. While alloying fundamentally changes the metal's internal structure at a molecular level, tempering modifies its microstructure to balance strength and ductility, collectively optimizing performance under mechanical stress.

Best Practices for Alloying and Tempering Metals

Best practices for alloying metals include precise control of composition and temperature to achieve desired mechanical properties, such as strength, corrosion resistance, and ductility. In tempering, controlled heating and cooling rates are critical to relieve internal stresses and improve toughness without compromising hardness. Proper integration of alloying and tempering processes enhances metal performance in applications like aerospace, automotive, and construction.

Choosing Between Alloying and Tempering for Your Project

Choosing between alloying and tempering depends on the specific performance requirements and application of the metal. Alloying enhances properties by mixing elements such as chromium, nickel, or manganese to improve strength, corrosion resistance, and toughness at the molecular level. Tempering, on the other hand, refines the microstructure of hardened steel through controlled heating, increasing ductility and reducing brittleness while maintaining hardness.

Alloying vs Tempering Infographic

materialdif.com

materialdif.com