Annealed metal is softened through controlled heating and gradual cooling, which increases its ductility and reduces internal stresses, making it easier to work with during manufacturing. Hardened metal undergoes rapid cooling processes like quenching, resulting in a strong, wear-resistant structure due to increased hardness but decreased flexibility. Selecting between annealed and hardened metal depends on the desired balance of strength, machinability, and durability required for specific applications.

Table of Comparison

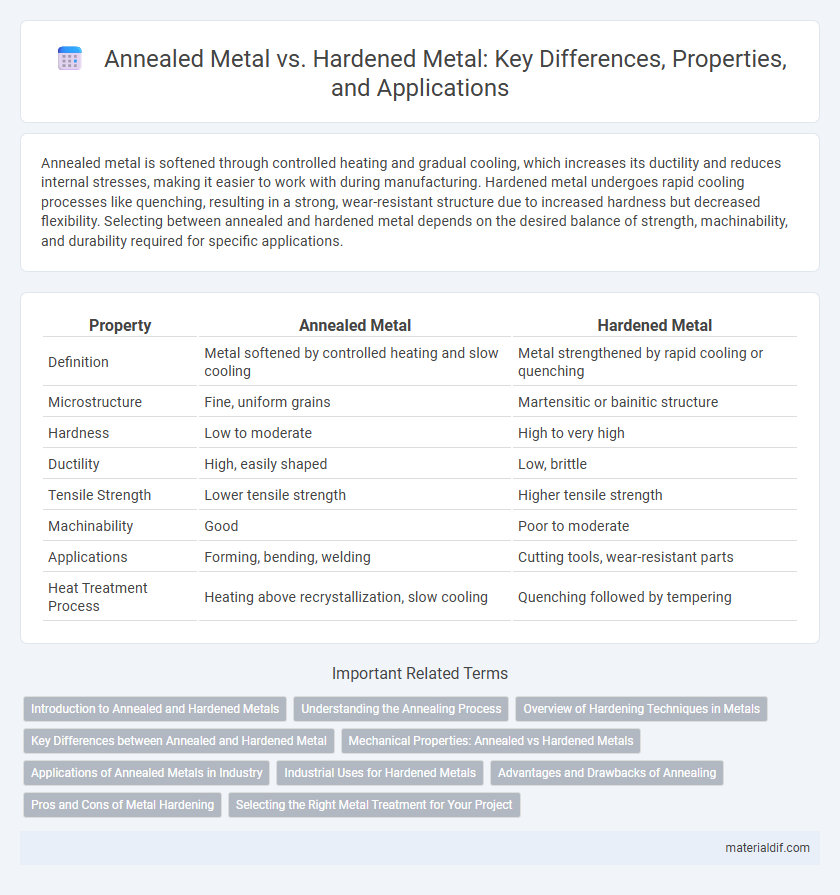

| Property | Annealed Metal | Hardened Metal |

|---|---|---|

| Definition | Metal softened by controlled heating and slow cooling | Metal strengthened by rapid cooling or quenching |

| Microstructure | Fine, uniform grains | Martensitic or bainitic structure |

| Hardness | Low to moderate | High to very high |

| Ductility | High, easily shaped | Low, brittle |

| Tensile Strength | Lower tensile strength | Higher tensile strength |

| Machinability | Good | Poor to moderate |

| Applications | Forming, bending, welding | Cutting tools, wear-resistant parts |

| Heat Treatment Process | Heating above recrystallization, slow cooling | Quenching followed by tempering |

Introduction to Annealed and Hardened Metals

Annealed metal undergoes a heat treatment process that softens the material, enhancing its ductility and reducing internal stresses for improved machinability. Hardened metal is subjected to controlled heating and rapid cooling, typically through quenching, which increases its hardness and tensile strength, making it more resistant to wear and deformation. These metallurgical treatments fundamentally alter the microstructure, impacting mechanical properties tailored for specific industrial applications.

Understanding the Annealing Process

The annealing process involves heating metal to a specific temperature and then slowly cooling it to remove internal stresses, increase ductility, and improve workability. This thermal treatment refines the metal's grain structure, making annealed metal softer and more malleable compared to hardened metal. Hardened metal undergoes rapid cooling after heating, resulting in increased hardness and strength but reduced flexibility.

Overview of Hardening Techniques in Metals

Hardening techniques for metals include quenching, tempering, and case hardening, which enhance strength and wear resistance by altering the metal's microstructure. Annealed metal undergoes a controlled heating and cooling process to relieve internal stresses and increase ductility, whereas hardened metal is subjected to rapid cooling or surface treatments to achieve greater hardness and durability. Common methods such as induction hardening and carburizing selectively harden the surface layer, improving fatigue resistance without compromising the metal's core toughness.

Key Differences between Annealed and Hardened Metal

Annealed metal undergoes a heat treatment process that softens the material, improving its ductility and reducing internal stresses, whereas hardened metal is subjected to rapid cooling techniques like quenching to increase its hardness and strength. The key differences include annealed metal being more malleable and easier to machine, while hardened metal offers superior wear resistance and durability. These contrasting properties determine their specific applications in manufacturing, with annealed metal favored for forming processes and hardened metal used where mechanical strength is critical.

Mechanical Properties: Annealed vs Hardened Metals

Annealed metal exhibits increased ductility and reduced hardness due to the softening process that relieves internal stresses, making it suitable for forming and machining. Hardened metal, achieved through quenching and tempering, significantly enhances tensile strength and hardness, resulting in improved wear resistance but decreased malleability. The trade-off between annealed and hardened metals lies in balancing mechanical properties for specific applications requiring flexibility versus durability.

Applications of Annealed Metals in Industry

Annealed metals are widely used in industries requiring high ductility and formability, such as automotive manufacturing, where they allow for easier stamping and shaping of sheet metals. These metals are essential in electrical applications due to their improved conductivity and reduced brittleness, making them ideal for wiring and connectors. In construction, annealed steel is favored for components that need to absorb stress without cracking, including structural beams and reinforcement bars.

Industrial Uses for Hardened Metals

Hardened metals exhibit increased strength and wear resistance, making them ideal for industrial applications such as cutting tools, machinery components, and heavy-duty fasteners. Unlike annealed metals, hardened metals withstand high stress and abrasive conditions, ensuring durability in manufacturing, construction, and automotive industries. Their enhanced hardness improves performance and extends the lifespan of equipment used in demanding environments.

Advantages and Drawbacks of Annealing

Annealed metal offers enhanced ductility and improved machinability, making it ideal for processes requiring shaping and welding. Its decreased hardness reduces brittleness, lowering the risk of cracking under stress, but this also means it has lower wear resistance compared to hardened metal. The main drawback of annealed metal is its reduced strength and hardness, which limits its use in high-stress or high-wear applications.

Pros and Cons of Metal Hardening

Metal hardening enhances strength, wear resistance, and durability by increasing hardness through heat treatment or alloying, making it ideal for cutting tools and structural components. However, hardened metal can become brittle and prone to cracking under heavy impact or stress, limiting its toughness and flexibility compared to annealed metal. Annealed metal offers improved ductility and machinability, allowing easier shaping and reducing the risk of fractures during forming processes.

Selecting the Right Metal Treatment for Your Project

Annealed metal offers enhanced ductility and reduced hardness, making it ideal for projects requiring extensive shaping or welding, while hardened metal provides superior strength and wear resistance for high-stress applications. Selecting the right metal treatment depends on the intended use, balancing flexibility and durability to meet specific performance criteria. Understanding the mechanical properties of annealed versus hardened metals ensures optimal material performance and longevity in your project.

Annealed Metal vs Hardened Metal Infographic

materialdif.com

materialdif.com